Abstract

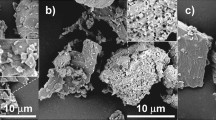

Biodegradable polymer plays a major role in Additive Manufacturing (AM) technologies due to its novel characteristics that include its complete degradability and eco-friendly nature. The present research work aims to obtain smooth and stable Poly Lactic Acid (PLA)/Eggshell particles (E) composite filaments with enhanced mechanical and thermal properties for additive manufacturing applications. Composite filaments were developed by varying the ratio of E/PLA to 4-6-8-10-12 weight percentages (wt.%) using a single screw extruder. A study of physical, chemical, mechanical, and thermal properties for the manufactured filaments was made. The extruded filaments were subjected to thermal analysis using Melt Flow Index (MFI) to obtain the optimum value for AM applications. XRD analysis made on 4 wt.% eggshell revealed a higher crystallinity than neat PLA. The thermal results of neat PLA and various weight compositions of E revealed there is a decrease in thermal stability and thermal decomposition due to an increase in filler content. 4 wt.% of E shows the good tensile strength of 49.29 MPa with smooth and stable E/PLA composite filaments during extrusion. The SEM images of the composites revealed the interaction between the filler and the matrix. Based on the experimental work, it is observed that the addition of eggshell powder into the PLA increases the mechanical properties with an optimum content of 4 wt.% of E.

Similar content being viewed by others

References

X. Tian, T. Liu, Q. Wang, A. Dilmurat, D. Li and G. Ziegmann, Recycling and Remanufacturing of 3D Printed Continuous Carbon Fiber Reinforced PLA Composites, J. Clean. Prod., 2017, 142, p 1609–1618.

R. Siva, G. Gopinatha, I. MouliPremchand, G. Mathiselvan, M. SaravanaKumar. Study on Morphological and Mechanical Properties on Treated and Untreated Veldt Grape/PLA Composites. Materials Today Proceedings, https://doi.org/10.1016/j.matpr.2021.06.425

M.A. Kreiger, M.L. Mulder, A.G. Glover and J.M. Pearce, Life Cycle Analysis of Distributed Recycling of Post-consumer High Density Polyethylene for 3-D Printing Filament, J. Clean. Prod., 2014, 70, p 90–96.

S.R. Begum, M.S. Kumar, C.I. Pruncu, M. Vasumathi and P. Harikrishnan, Optimization and Fabrication of Customized Scaffold Using Additive Manufacturing to Match the Property of Human Bone, J. Mater. Eng. Perform., 2021 https://doi.org/10.1007/s11665-020-05449-7

Z. Liu, Q. Lei and S. Xing, Mechanical Characteristics of Wood, Ceramic, Metal and Carbon Fiber-Based PLA Composites Fabricated by FDM, J. Market. Res., 2019, 8(5), p 3741–3751.

Sivagnanamani, G. S., Ramesh, P., Kumar, M. H., and Arul Mozhi Selvan, V. (2021). Fracture Analysis of Fused Deposition Modelling of Bio-composite Filaments. In Fracture Failure Analysis of Fiber Reinforced Polymer Matrix Composites (pp. 71-84). Springer, Singapore.

S. Kumar and A. Czekanski, Development of Filaments Using Selective Laser Sintering Waste Powder, J. Clean. Prod., 2017, 165, p 1188–1196.

V. Hembrick-Holloman, T. Samuel, Z. Mohammed, S. Jeelani and V.K. Rangari, Ecofriendly Production of Bioactive Tissue Engineering Scaffolds Derived from Egg-and Sea-Shells, J. Market. Res., 2020, 9(6), p 13729–13739.

Boparai, K. S., Singh, R., & Singh, H. (2016). Experimental Investigations for Development of Nylon6-Al-Al2O3 Alternative FDM Filament. Rapid Prototyp. J.

I. Antoniac, D. Popescu, A. Zapciu, A. Antoniac, F. Miculescu and H. Moldovan, Magnesium Filled Polylactic Acid (PLA) Material for Filament Based 3D Printing, Materials, 2019, 12(5), p 719.

F. Daver, K.P.M. Lee, M. Brandt and R. Shanks, Cork–PLA Composite Filaments for Fused Deposition Modelling, Compos. Sci. Technol., 2018, 168, p 230–237.

R. Singh, S. Singh and F. Fraternali, Development of In-house Composite Wire Based Feed Stock Filaments of Fused Deposition Modelling for Wear-Resistant Materials and Structures, Compos. B Eng., 2016, 98, p 244–249.

C.E. Corcione, E. Palumbo, A. Masciullo, F. Montagna and M.C. Torricelli, Fused Deposition Modeling (FDM): An Innovative Technique Aimed at Reusing Lecce Stone Waste for Industrial Design and Building Applications, Constr. Build. Mater., 2018, 158, p 276–284.

Wu, D., Spanou, A., Diez-Escudero, A., & Persson, C. (2020). 3D-Printed PLA/HA Composite Structures as Synthetic Trabecular Bone: A Feasibility Study Using Fused Deposition Modeling. J. Mech. Behav. Biomed. Mater., 103, 103608.

Heidari-Rarani, M., Rafiee-Afarani, M., & Zahedi, A. M. (2019). Mechanical Characterization of FDM 3D Printing of Continuous Carbon Fiber Reinforced PLA Composites. Compos. Part B: Engineering, 175, 107147.

Boparai, K. S., Singh, R., & Singh, H. (2016). Process Optimization of Single Screw Extruder for Development of Nylon 6-Al-Al2O3 Alternative FDM Filament. Rapid Prototyp. J..

R. Singh, R. Kumar, I. Farina, F. Colangelo, L. Feo and F. Fraternali, Multi-material Additive Manufacturing of Sustainable Innovative Materials and Structures, Polymers, 2019, 11(1), p 62.

K.S.S. Kumar, M. Vivekananthan, M. Saravanakumar and F.S. Raj, Investigation of Physico Chemical, Mechanical and Thermal Properties of the Guettarda Speciosa Bark Fibers, Materials Today: Proceedings, 2021, 37, p 1845–1849. https://doi.org/10.1016/j.matpr.2020.07.443

A.M. Abdullah, T.N.A.T. Rahim, W.N.F.W. Hamad, D. Mohamad, H.M. Akil and Z.A. Rajion, Mechanical and Cytotoxicity Properties of Hybrid Ceramics Filled Polyamide 12 Filament Feedstock for Craniofacial Bone Reconstruction via Fused Deposition Modelling, Dent. Mater., 2018, 34(11), p e309–e316.

R. Donate, M. Monzón, Z. Ortega, L. Wang, V. Ribeiro, D. Pestana and R.L. Reis, Comparison Between Calcium Carbonate and β-Tricalcium Phosphate as Additives of 3D Printed Scaffolds with Polylactic Acid Matrix, J. Tissue Eng. Regen. Med., 2020, 14(2), p 272–283.

M. Janek, V. Žilinská, V. Kovár, Z. Hajdúchová, K. Tomanová, P. Peciar and Ľ Bača, Mechanical Testing of Hydroxyapatite Filaments for Tissue Scaffolds Preparation by Fused Deposition of Ceramics, J. Eur. Ceram. Soc., 2020, 40(14), p 4932–4938.

Z. Weng, J. Wang, T. Senthil and L. Wu, Mechanical and Thermal Properties of ABS/Montmorillonite Nanocomposites for Fused Deposition Modeling 3D Printing, Mater. Des., 2016, 102, p 276–283.

K.S. Boparai, R. Singh, F. Fabbrocino and F. Fraternali, Thermal Characterization of Recycled Polymer for Additive Manufacturing Applications, Compos. B Eng., 2016, 106, p 42–47.

Rahimizadeh, A., Kalman, J., Fayazbakhsh, K., & Lessard, L. (2019). Recycling of Fiberglass wind Turbine Blades into Reinforced Filaments for Use in Additive Manufacturing. Compos. Part B: Eng., 175, 107101.

L. Delva, K. Ragaert, J. Degrieck and L. Cardon, The Effect of Multiple Extrusions on the Properties of Montmorillonite Filled Polypropylene, Polymers, 2014, 6(12), p 2912–2927.

D. Filgueira, S. Holmen, J.K. Melbø, D. Moldes, A.T. Echtermeyer and G. Chinga-Carrasco, Enzymatic-Assisted Modification of Thermomechanical Pulp Fibers to Improve the Interfacial Adhesion with Poly(lactic acid) for 3D Printing, ACS Sustain. Chem. Eng., 2017, 5(10), p 9338–9346.

Wang, P., Zou, B., Ding, S., Huang, C., Shi, Z., Ma, Y., & Yao, P. (2020). Preparation of Short CF/GF Reinforced PEEK Composite Filaments and Their Comprehensive Properties Evaluation for FDM-3D Printing. Compos. Part B: Eng., 198, 108175.

Z. Lule and J. Kim, Nonisothermal Crystallization of Surface-Treated Alumina and Aluminum Nitride-Filled Polylactic Acid Hybrid Composites, Polymers, 2019, 11(6), p 1077.

B. Ashok, S. Naresh, K.O. Reddy, K. Madhukar, J. Cai, L. Zhang and A.V. Rajulu, Tensile and Thermal Properties of Poly(lactic acid)/Eggshell Powder Composite Films, Int. J. Polym. Anal. Charact., 2014, 19(3), p 245–255.

R. Nasrin, S. Biswas, T.U. Rashid, S. Afrin, R.A. Jahan, P. Haque and M.M. Rahman, Preparation of Chitin-PLA Laminated Composite for Implantable Application, Bioactive Mater., 2017, 2(4), p 199–207.

Yuniarto, K., Purwanto, Y. A., Purwanto, S., Welt, B. A., Purwadaria, H. K., & Sunarti, T. C. (2016, April). Infrared and Raman Studies on Polylactide Acid and Polyethylene Glycol-400 Blend. In AIP Conference Proceedings (Vol. 1725, No. 1, p. 020101). AIP Publishing LLC.

Brito, G. F., Agrawal, P., & Mélo, T. J. (2016, September). Mechanical and Morphological Properties of PLA/BioPE Blend Compatibilized with E‐GMA and EMA‐GMA Copolymers. In Macromolecular Symposia (Vol. 367, No. 1, pp. 176-182).

Huang, Y. Z., Ji, Y. R., Kang, Z. W., Li, F., Ge, S. F., Yang, D. P., Fan, X. Q. (2020). Integrating Eggshell-Derived CaCO3/MgO Nanocomposites and Chitosan into a Biomimetic Scaffold for Bone Regeneration. Chem. Eng. J., 395, 125098.

M.S. Tizo, L.A.V. Blanco, A.C.Q. Cagas, B.R.B.D. Cruz, J.C. Encoy, J.V. Gunting and V.I.F. Mabayo, Efficiency of Calcium Carbonate from Eggshells as an Adsorbent for Cadmium Removal in Aqueous Solution, Sustain. Environ. Res., 2018, 28(6), p 326–332.

J.P. Mofokeng, A.S. Luyt, T. Tábi and J. Kovács, Comparison of Injection Moulded, Natural Fibre-Reinforced Composites with PP and PLA as Matrices, J. Thermoplast. Compos. Mater., 2012, 25(8), p 927–948.

E.H. Backes, L.D.N. Pires, L.C. Costa, F.R. Passador and L.A. Pessan, Analysis of the Degradation During Melt Processing of PLA/Biosilicate® Composites, J. Compos. Sci., 2019, 3(2), p 52.

K. Kaewtatip, C. Chiarathanakrit and S.A. Riyajan, The Effects of Egg Shell and Shrimp Shell on the Properties of Baked Starch Foam, Powder Technol., 2018, 335, p 354–359.

S.T. Morbale, S.S. Shinde, S.D. Jadhav, M.B. Deshmukh and S.S. Patil, Modified Eggshell Catalyzed, One-pot Synthesis and Antimicrobial Evaluation of 1, 4-dihydropyridines and Polyhydroquinolines, Lett, 2015, 7, p 169–182.

C.E. Tanase and I. Spiridon, PLA/chitosan/keratin Composites for Biomedical Applications, Mater. Sci. Eng., C, 2014, 40, p 242–247.

A. Potnuru and Y. Tadesse, Investigation of Polylactide and Carbon Nanocomposite Filament for 3D Printing, Prog. Addit. Manuf., 2019, 4(1), p 23–41.

H. Daraei, A. Mittal, J. Mittal and H. Kamali, Optimization of Cr (VI) Removal onto Biosorbent Eggshell Membrane: Experimental & Theoretical Approaches, Desalin. Water Treat., 2014, 52(7–9), p 1307–1315.

Y. Li, C. Han, Y. Yu, L. Xiao and Y. Shao, Crystallization Behaviors of Poly(lactic acid) Composites Fabricated Using Functionalized Eggshell Powder and Poly(ethylene glycol), Thermochim. Acta, 2018, 663, p 67–76.

Acknowledgment

The authors thank the Centre for Research, Anna University, Chennai-600025. For the financial support in the form of fellowship (Anna Centenary Research Fellowship, ACRF) (Ref. No. CFR/ACRF/2018/AR1/5).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sivagnanamani, G.S., Begum, S.R., Siva, R. et al. Experimental Investigation on Influence of Waste Egg Shell Particles on Polylactic Acid Matrix for Additive Manufacturing Application. J. of Materi Eng and Perform 31, 3471–3480 (2022). https://doi.org/10.1007/s11665-021-06464-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06464-y