Abstract

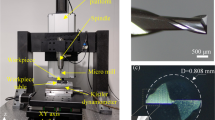

TB8 titanium alloy has good comprehensive properties and has been widely used in the aerospace field. In this paper, the laser-assisted micromachining (LAMM) of TB8 titanium alloy was carried out to study the influence laws of laser beam power and laser scanning speed on the laser heat-affected zone (HAZ) and establish the finite element temperature field model. The experimental results of conventional machining and LAMM were compared. The effects of laser beam power, cutting speed and cutting depth on microstructure, surface microhardness, and surface residual stress of TB8 titanium alloy were studied and analyzed. The experimental results show that the laser HAZ depth and width decrease with the increase of cutting speed and increase with the increase of laser beam power. The simulation has a good correlation with the experiment, which proves the correctness of the simulation. The LAMM can reduce the grain breakage of the machining profile. With the increase of cutting depth and laser beam power, the grain breakage decreases first and then increases, and the cutting speed is the opposite. When the cutting speed is 50 mm/s, the maximum improvement is 16.9%. The LAMM can reduce the surface residual compressive stress and improve the surface hardness of the workpiece.

Similar content being viewed by others

Reference

Y. Chen, The Research on Microstructure and Mechanical Properties of β 21S Titanium Alloy, China Acad. J. Electron. Publ. House (1997), p 11–14, in China

W. Ye, X. Tuo and S. Wang, Deformation behavior of β21S titanium alloy under hot compression, Chin. J. Rare Met., 2002 https://doi.org/10.13373/j.cnki.cjrm (in China)

H. Vigié, A. Soula and B. Viguier, Aging of the β21s Titanium Alloy, Solid State Phenom., 2017, 258, p 550–553.

S. Sun, M. Brandt and M.S. Dargusch, Thermally Enhanced Machining of Hard-to-Machine Materials, Int. J. Mach. Tools Manuf, 2010, 50(8), p 663–680. https://doi.org/10.1016/j.ijmachtools.2010.04.008

K. Venkatesan, R. Ramanujam and P. Kuppan, A Review on Conventional and Laser Assisted Machining of Aluminium Based Metal Matrix Composites, Eng. Rev, 2014, 34(2), p 75–84.

J. Xu, X. Nie, C. Zhai, W. Ren, Z. Lian, J. Tian and H. Yu, The Study on Surface Quality and Tool Wear on Laser-Assisted Micromachining of β21s Titanium Alloy, Int. J. Adv. Manuf. Technol, 2020, 110(9–10), p 2283–2293. https://doi.org/10.1007/s00170-020-05970-y

W. Zhang, Q. Yang, Y. Tan, M. Ma, S. Xiang and F. Zhao, Simulation and Experimental Study of Dynamical Recrystallization Kinetics of tb8 Titanium Alloys, Materials (Basel), 2020, 13(19), p 1–19. https://doi.org/10.3390/ma13194429

M. Balbaa, M.N.A. Nasr and H. Elgama, A Sensitivity Analysis on the Effect of Laser Power on Residual Stresses When Laser-assisted Machining AISI 4340, Procedia CIRP, 2017, 58, p 31–36. https://doi.org/10.1016/j.procir.2017.03.182

S. Melkote, M. Kumar, F. Hashimoto and G. Lahoti, Laser Assisted Micro-Milling of Hard-to-Machine Materials, CIRP Ann. Manuf. Technol., 2009, 58(1), p 45–48. https://doi.org/10.1016/j.cirp.2009.03.053

O.A. Shams, A. Pramanik and T.T. Chandratilleke, Thermal-assisted machining of titanium alloys, Advanced manufacturing technologies. K. Gupta Ed., Springer, 2017, p 49–76. https://doi.org/10.1007/978-3-319-56099-1_3

S. Agrawal and S.S. Joshi, Analytical Modelling of Residual Stresses in Orthogonal Machining of AISI4340 Steel, J. Manuf. Process, 2013, 15(1), p 167–179. https://doi.org/10.1016/j.jmapro.2012.11.004

D.H. Kim and C.M. Lee, A Study of Cutting Force and Preheating-Temperature Prediction for Laser-Assisted Milling of Inconel 718 and AISI 1045 Steel, Int. J. Heat Mass Transf., 2014, 71, p 264–274. https://doi.org/10.1016/j.ijheatmasstransfer.2013.12.021

B. Huang, C. Li, L. Shi, G. Qiu, and T. ZUO, China Materials Engineering Symposium Volume 4 Nonferrous Metal Materials Engineering, Chemical Industry Press, 2005, Volume 1, p 673, in China

J.A. Becker, K.D. Berg, M.A. Røder, K. Brasso, and P. Iversen, Cytoreductive Prostatectomy in Metastatic Prostate Cancer: A Systematic Review, Scand. J. Urol., 2018, 52, p 1–7. https://doi.org/10.1080/21681805.2017.1363816

T. Yu, L. Wang, Y. Zhao, H. Wang, K. Geng and H. Ni, Growth Behavior of β-Grain of Near β-type High Strength Titanium Alloy Ti-26, J. Zhengzhou Univ., 2009, 30(1), p 7–9. (in China)

Z. Wei, X. Shewei, G. Peng, L. Qian and C. Jun, Research on Grain Growth Behavior of TB8 Titanium Alloy, Prog. Titan. Ind., 2014, 31, p 6–8. (in China)

Z. Peng and P. Yan, Investigation into Residual Stress of Austenitic 304 Stainless Steel at Cryogenic Temperature, Binggong Xuebao/Acta Armamentarii, 2019, 40(6), p 1271–1276. https://doi.org/10.3969/j.issn.1000-1093.2019.06.018,inChina

Acknowledgments

This work was supported by the National Natural Science Foundation of China (No. U19A20103), the China Postdoctoral Science Foundation (No. 2019M661184), the “111” Project of China (No. D17017), and the National Key Research and Development Program of China (No. 2018YFB1107400).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xu, J., Sun, G., Zhai, C. et al. Study on the Heat-Affected Zone, Microstructure, and Surface Quality of TB8 Titanium Alloy Treated by Laser-Assisted Micromachining. J. of Materi Eng and Perform 31, 2978–2990 (2022). https://doi.org/10.1007/s11665-021-06431-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06431-7