Abstract

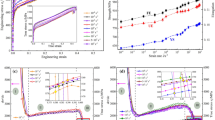

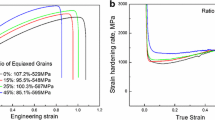

The mechanical behaviors and microstructural characteristics of three twinning-induced plasticity (TWIP) steels prepared using directional solidification at withdrawal rates of 3, 8, and 15 µms−1 (abbreviated as DS3, DS8, and DS15, respectively) were investigated. The results showed that all the samples solidified steadily in a cellular growth mode. The dendrite spacing decreased on increasing the withdrawal rate, but eliminated grains resulted from increased growth competition. At a low strain rate of 2.27×10−3 s−1, DS8 exhibited the best mechanical properties because of the adequately stimulated TWIP effect with well-developed twin structures and good deformation synergy between columnar grains being conducive to uniform stress distribution. Therefore, the work hardening ability significantly improved, with the highest working hardening exponent, ni, obtained at a high strain level. This was accompanied by a remarkably enhanced uniform plastic deformation ability. A weakened TWIP effect occurred due to suppressed twinning with fewer and nonuniform twins structures at a high strain rate of 3.79×10-1 s-1. The high strain rate was evident to be not conducive to the activation of planar slip for directionally solidified samples, resulting in fewer and inhomogeneous slip systems. This effectively weakened twinning with relatively strong dislocation gliding instead. This remarkably decreased all the ni values in the medium-to-high strain range, leading to a significantly decreased plastic deformation ability and finally resulting in severely degraded plasticity, especially for DS8.

Similar content being viewed by others

Reference

O. Grassel, L. Kruger, G. Frommeyer and L.W. Meyer, High Strength Fe-Mn-(Al, Si)TRIP/TWIP Steels Development-Properties-Application, Int. J. Plastic., 2000, 16, p 1391–1409.

G. Frommeyer, U. Brux and P. Neumann, Supra-Ductile and High-Strength Manganese-TRIP/TWIP Steels for High Energy Absorption Purpose, TSIJ Int., 2003, 43(3), p 438–446.

S. Vercammen, B. Blanpain, B.C.D. Cooman and P. Wollantsa, Cold Rolling Behavior of an Austenitic Fe-30Mn-3Al-3Si TWIP-Steel: The Importance of Deformation Twinning, Acta Mater., 2004, 52, p 2005–2012.

M. Koyama, T. Sawaguchi and K. Tsuzaki, Selective Appearance of ε-martensitic Transformation and Dynamic Strain Aging in Fe-Mn-C Austenitic Steels, Phil. Mag. Lett., 2012, 92, p 145–152.

S.K. Mishra, S.M. Tiwari, A.M. Kumar and L.G. Hector Jr., Effect of Strain and Strain Path on Texture and Twin Development in Austenitic Steel with Twinning-Induced Plasticity, Metall. Mater. Trans. A., 2012, 43A, p 1598–1609.

V. Shterner, A. Molotnikov, I. Timokhina, Y. Estrin and H. Beladi, A Constitutive Model of the Deformation Behavior of Twinning Induced Plasticity (TWIP) Steel at Different Temperatures, Mater. Sci. Eng. A., 2014, 613, p 224–231.

D.T. Pierce, J.A. Jiménez, J. Bentley, D. Raabe, C. Oskay and J.E. Wittig, The Influence of Manganese Content on the Stacking Fault and Austenite/ε-martensite Interfacial Energies in Fe-Mn-(Al-Si) Steels Investigated by Experiment and Theory, Acta Mater., 2014, 68, p 238–253.

S. Curtze and V.T. Kuokkala, Dependence of Tensile Deformation Behavior of TWIP Steels on Stacking Fault Energy, Temperature and Strain Rate, Acta Mater., 2010, 58(15), p 5129–5141.

Y. Ha, H. Kim, K.H. Kwon, S.G. Lee, S. Lee and N.J. Kim, Microstructural Evolution in Fe-22Mn-0.4C Twinning-Induced Plasticity Steel During High Strain Rate Deformation, Metall. Mater. Trans. A., 2005, 46, p 545–548.

S. Allain, J.P. Chateau, O. Bouaziz, S. Migot and N. Guelton, Correlations Between the Calculated Stacking Fault Energy and the Plasticity Mechanisms in Fe-Mn-C Alloys, Mater. Sci. Eng. A., 2004, 387-389, p 158–162.

A. Saeed-Akbari, J. Imlau, U. Prahl and W. Bleck, Derivation and Variation in Composition-Dependent Stacking Fault Energy Maps Based on Subregular Solution Model in High-Manganese Steels, Metall. Mater. Trans. A., 2009, 40A, p 3076–3090.

C. Haase, L.A. Barralesmora, D.A. Molodov and G. Gottstein, Tailoring the Mechanical Properties of a Twinning-Induced Plasticity Steel by Retention of Deformation Twins During Heat Treatment, Metall. Mater. Trans. A., 2013, 44, p 4445–4449.

P. Kusakin, A. Belyakov, C. Haase, R. Kaibysheva and D.A. Molodovb, Microstructure Evolution and Strengthening Mechanisms of Fe-23Mn-0.3C-1.5Al TWIP Steel During Cold Rolling, Mater. Sci. Eng. A., 2014, 617, p 52–60.

Y. Yang, C.F. Li and K.H. Song, Effect of Strain Rate on the Microstructures and Properties of Hot-Rolled TWIP Steel in the Solution Condition, Adv. Mater. Res., 2012, 430–432, p 256-259.

Y.I. Wei-Fa, D.Y. Zhu, H.U. Zhen-Ming, Z.B. Yang and S.M. Lin, Effect of Hot Rolling Deformation on Microstructure Defects and Mechanical Properties of High Carbon TWIP Steel, Mater. Sci. Tech-lond., 2011, 19, p 45–49.

O. Bouaziz, C.P. Scott and G. Petitgand, Effect of Grain and Twin Boundaries on the Hardening Mechanisms of Twinning-Induced Plasticity Steels, Scr. Mater., 2009, 60, p 714–716.

R. Ueji, N. Tsuchida, H. Fujii, D. Kondo and K. Kunishige, Effect of Grain Size on Tensile Properties of TWIP Steel, J Jpn I Met., 2007, 71(9), p 815–821.

G. Dini, A. Najafizadeh, R. Ueji and S.M. Monir-Vaghefi, Improved Tensile Properties of Partially Recrystallized Submicron Grained TWIP Steel, Mater. Lett., 2010, 64, p 15–18.

G. Dini, A. Najafizadeh, R. Ueji and S.M. Monir-Vaghefi, Tensile Deformation Behavior of High Manganese Austenitic Steel: The Role of Grain Size, Mater Des., 2010, 31, p 3395–3402.

T. Lee, M. Koyama, K. Tsuzaki, Y.H. Lee and C.S. Lee, Tensile Deformation Behavior of Fe-Mn-C TWIP Steel with Ultrafine Elongated Grain Structure, Mater Lett., 2012, 75, p 169–171.

L. Wang, J.A. Benito, J. Calvo and J.M. Cabrera, Equal Channel Angular Pressing of a TWIP Steel: Microstructure and Mechanical Response, J Mater Sci., 2017, 52, p 6291–6309.

W.H. Jiang, X.F. Sun, H.R. Guan and Z.Q. Hu, Influence of high-Temperature Air Pre-exposure on Mechanical Strength of a Directionally Solidified Cobalt-Base Superalloy, J. Mater Sci., 2001, 36(4), p 859–863.

H. Bei, G.M. Pharr and E.P. George, A Review of Directionally Solidified Intermetallic Composites for High-Temperature Structural Applications, J Mater Sci., 2004, 39(12), p 3975–3984.

X.B. Zhao, L. Liu, Z.H. Yu, W.G. Zhang, J. Zhang and H.G. Fu, Influence of Directional Solidification Variables on the Microstructure and Crystal Orientation of AM3 Under High Thermal Gradient, J Mater Sci., 2009, 45(22), p 6101–6107.

J.J. Tang and X. Xue, Phase-field Simulation of Directional Solidification of a Binary Alloy under Different Boundary Heat Flux Conditions, J. Mater Sci., 2009, 44(3), p 745–753.

H.R. Zhang, X.X. Tang, L. Zhou, M. Gao, C.G. Zhou and H. Zhang, Interactions Between Ni-44Ti-5Al-2Nb-Mo Alloy and Oxide Ceramics During Directional Solidification Process, J. Mater Sci., 2012, 47, p 6451–6458.

Y. Tomita and K. Okabayashi, Tensile Stress-Strain Analysis of Cold Worked Metals and Steels and Dual-Phase Steels, Metall. Mater. Trans. A., 1985, 16, p 865–872.

M.S. Nagorka, C.G. Levi, G.E. Lucas and S.D. Ridder, The Potential of Rapid Solidification in Oxide-Dispersion-Strengthened Copper Alloy Development, Mater. Sci. Eng. A., 1991, 142(2), p 277–289.

Z. Jiang, J. Lian and J. Chen, Strain Hardening Behaviour and its Relationship to Tensile Mechanical Properties of Dual Phase Steel, Mater. Sci. Technol., 1992, 8, p 1075–1081.

M. Umemoto, Z.G. Liu, S. Sugimoto and K. Tsuchiya, Tensile Stress-Strain Analysis of Single-Structure Steels, Metall. Mater. Trans. A., 2000, 31, p 1785–1794.

G. Dini, R. Ueji, A. Najafizadeh and S.M. Monir-Vaghefi, Flow Stress Analysis of TWIP Steel via the XRD Measurement of Dislocation Density, Mater. Sci. Eng. A., 2010, 527, p 2759–2763.

O. Bouaziz, S. Allain, C.P. Scott, P. Cugy and D. Barbier, High Manganese Austenitic Twinning Induced Plasticity Steels: A Review of the Microstructure Properties Relationships, Curr. Opin. Solid State Mater. Sci., 2011, 15, p 141–168.

I. Gutierrez-Urrutia and D. Raabe, Multistage Strain Hardening Through Dislocation Substructure and Twinning in a High Strength and Ductile Weight-Reduced Fe-Mn-Al-C Steel, Acta Mater., 2012, 60, p 5791–5802.

D.A. Hughes, N. Hansen and D.J. Bammann, Geometrically Necessary Boundaries, Incidental Dislocation Boundaries and Geometrically Necessary Dislocations, Scripta Mater., 2003, 48, p 147–153.

K. Huang and R.E. Logé, A Review of Dynamic Recrystallization Phenomena in Metallic Materials, Mater Des., 2016, 111, p 548–574.

L.S. Toth, Y. Estrin, R. Lapovok and C. Gu, A Model of Grain Fragmentation Based on Lattice Curvature, Acta Mater., 2010, 58, p 1782–1794.

I. Gutierrez-Urrutia, S. Zaefferer and D. Raabe, The Effect of Grain Size and Grain Orientation on Deformation Twinning in a Fe-22wt.%Mn-06wt.%C TWIP Steel, Mater. Sci. Eng. A, 2010, 527, p 3552–60.

E.E. Pattersona, D.P. Fielda and Y.D. Zhang, Characterization of Twin Boundaries in an Fe-17.5Mn-0.56C Twinning Induced Plasticity Steel, Mater, Charact., 2013, 85, p 100–110.

I. Karaman, H. Sehitoglu, H.J. Maier and Y.I. Chumlyakov, Competing Mechanisms and Modeling of Deformation in Austenitic Stainless Steel Single Crystals with and Without Nitrogen, Acta Mater., 2001, 49(19), p 3919–3933.

X. Wang, J.A. Muñiz-Lerma, O. Sanchez-Mata, M. Attarian Shandiz, N. Brodusch, R. Gauvin and M. Brochu, Characterization of Single Crystalline Austenitic Stainless Steel Thin Struts Processed by Laser Powder Bed Fusion, Scr. Mater., 2019, 163, p 51–56.

D. Raabe, M. Sachtleber, H. Weiland, G. Scheele and Z. Zhao, Grain-Scale Micromechanics of Polycrystal Surfaces During Plastic Straining, Acta Mater., 2003, 51, p 1539–1560.

I. Karaman, H. Sehitoglu, K. Gall, Y.I. Chumlyakov and H.J. Maier, Deformation of Single Crystal Hadfield Steel by Twinning and Slip, Acta Mater., 2000, 48, p 1345–1359.

H. Beladi, I.B. Timokhina, Y. Estrin, J. Kim, B.C. De Cooman and S.K. Kim, Orientation Dependence of Twinning and Strain Hardening Behaviour of a High Manganese Twinning Induced Plasticity Steel with Polycrystalline Structure Acta, Materialia, 2011, 59, p 7787–7799.

N.P. Gurao, P. Kumar, B. Bhattacharya, A. Haldar and S. Suwas, Evolution of Crystallographic Texture and Microstructure During Cold Rolling of Twinning-Induced Plasticity (TWIP) Steel: Experiments and Simulations, Metall. Mater. Trans. A, 2012, 43, p 5193–5201.

V. Tari, A.D. Rollett, H.E. Kadiri, H. Beladi, A.L. Oppedal and R.L. King, The Effect of Deformation Twinning on Stress Localization in a Three Dimensional TWIP Steel Microstructure, Modelling Simul. Mater. Sci. Eng., 2015, 23, p 045010.

M.X. Huang, Z.Y. Liang and Z.C. Luo, Critical Assessment 15: Science of Deformation and Failure Mechanisms in Twinning Induced Plasticity Steels, Mater. Sci. Technol., 2015, 31, p 1265–12702.

Z.Y. Liang, Z.C. Luo and M.X. Huang, Temperature Dependence of Strengthening Mechanisms in a Twinning-Induced Plasticity Steel, Int. J. Plast., 2019, 116, p 192–202.

J.S. Jeong, Y.M. Koo, I.K. Jeong, S.K. Kim and S.K. Kwon, Micro-Structural Study of High-Mn TWIP Steels using Diffraction Profile Analysis, Mater. Sci. Eng. A, 2011, 530, p 128–134.

A.S. Hamadaa, A. Kisko, A. Khosravifard, M.A. Hassan, L.P. Karjalainen and D. Porter, Ductility and Formability of Three High-Mn TWIP Steels in Quasi-Static and High-Speed Tensile and Erichsen Tests, Mater. Sci. Eng. A, 2018, 712, p 255–265.

H.R. Abedi, A. Zarei-Hanzaki, S.M. Fatemi-Varzaneh and A.A. Roostaei, The Semi-Solid Tensile Deformation Behavior of Wrought AZ31 Magnesium Alloy, Mater. Des., 2010, 31, p 4386–4391.

A.R. Khalesian, A. Zarei-Hanzaki, H.R. Abedi and F. Pilehva, An Investigation into the Room Temperature Mechanical Properties and Microstructural Evolution of Thermomechanically Processed TWIP Steel, Mater. Sci. Eng. A., 2014, 596, p 200–206.

Acknowledgment

This work was jointly supported by the National Natural Science Foundation of China (51701206), Natural Science Basic Research Program of Shaanxi (2019JQ-833), Anhui Natural Science Foundation (1808085QE166), Special Scientific Research Project of Shanxi Education Committee (19JQ0974), and Doctoral Research Initiation Project of Yan'an University (YDBD2018-21)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare there is no conflicts of interest regarding the publication of this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, D., Wang, W., Huang, Y. et al. An Investigation on Microstructures and Mechanical Properties of Twinning-Induced Plasticity Steels Prepared by Directional Solidification. J. of Materi Eng and Perform 31, 3326–3340 (2022). https://doi.org/10.1007/s11665-021-06423-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06423-7