Abstract

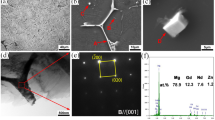

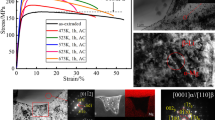

The microstructure characteristics and the elevated-temperature tensile behavior of Al-7Si-0.3Mg alloys with Zr/Hf additions were studied. The results showed that the individual addition of Zr promoted the precipitation of β" precipitates and the best effect was achieved by their combined addition. The individual addition of Zr or Hf and the combined addition of Zr and Hf in alloy could cause a reduction in the elevated-temperature tensile strength. Al-7Si-0.3Mg-0.14Zr-0.44Hf alloy displayed a noticeable increase in the ductility coupled with a remarkable decrease in the strength at elevated-temperature tensile test. The degradation in the strength of all the alloys was attributed to the phase transformation and coarsening behavior. The pre-β and β precipitates played the main strengthening effect because of the fact that the additional Zr and/or Hf containing dispersoids (i.e., Si-Zr/Hf) had relatively large size, nanobelt/rectangle-like morphology, and thereby low number density and volume fraction.

Similar content being viewed by others

References

P. Prasad, Characterization of New, Cast, High Temperature Aluminum Alloys for Diesel Engine Applications, University of Cincinnati, PhD Diss., 2006.

M. Javidani and D. Larouche, Application of cast Al–Si Alloys in Internal Combustion Engine Components, Int. Mater. Rev., 2014, 59, p 132–158.

M. Fadaei, H. Vafadar and A. Noorpoor, New Thermo-Mechanical Analysis of Cylinder Heads Using A Multi-Field Approach, Sci. Iran. B, 2011, 18, p 66–74.

D. Pierce, A. Haynes, J. Hughes, R. Graves, P. Maziasz, G. Muralidharan, A. Shyam, B. Wang, R. England and C. Daniel, High Temperature Materials for Heavy Duty Diesel Engines: Historical and Future Trends, Prog. Mater. Sci., 2019, 103, p 109–179.

H. Elhadari, H. Patel, D. Chen and W. Kasprzak, Tensile and Fatigue Properties of a Cast Aluminum Alloy with Ti, Zr and V Additions, Mater. Sci. Eng. A, 2011, 528, p 8128–8138.

Z.Z. Zhao, H.X. Yin, A.M. Zhao et al., Effect of Sc Micro Alloying Addition on Microstructure and Mechanical Properties of as-cast Al–12Si Alloy, Mater. Sci. Eng. A, 2014, 35, p 133–137.

S. Mondol, S. Kashyap and S. Kumar, Improvement of High Temperature Strength of 2219 Alloy by Sc and Zr Addition Through a Novel Three-Stage Heat Treatment Route, Mater. Sci. Eng. A, 2018, 732, p 157–166.

S.K. Shaha, F. Czerwinski, W. Kasprzak, J. Friedman and D.L. Chen, Improving High-Temperature Tensile and Low-Cycle Fatigue Behavior of Al-Si-Cu-Mg Alloys Through Micro-Additions of Ti, V, and Zr, Metall. Mater. Trans. A, 2015, 46, p 3063–3078.

H.L. Huang, Y.H. Dong, Y. Xing, Z.H. Jia and Q. Liu, Low Cycle Fatigue Behaviour at 300 °C and Microstructure of Al-Si-Mg Casting Alloys with Zr and Hf Additions, J. Alloy. Compd., 2018, 765, p 1253–1262.

K.E. Knipling, D.C. Dunand and D.N. Seidman, Criteria for Developing Castable, Creep-Resistant Aluminum-Based Alloys, Z. Metallkd, 2006, 97, p 246–265.

J. Ding, P. Zhang, X.W. Li, L.S. Wang et al. Microstructure and Thermal Stability Evolution Behavior of Sc-containing A356.2 Aluminum Alloy Under Cyclic Thermal Exposure Conditions. Mater. Sci. Eng. A, 2018, 723, p 165–173.

W. Kasprzak, B.S. Amirkhiz and M. Niewczas, Structure and Properties of cast Al-Si Based Alloy With Zr-V-Ti Additions and its Evaluation of High Temperature Performance, J. Alloy. Compd., 2014, 595, p 67–79.

A.M.A. Mohamed, F.H. Samuel and S.A. Kahtani, Microstructure, Tensile Properties and Fracture Behavior of High Temperature Al-Si-Mg-Cu Cast Alloys, Mater. Sci. Eng. A, 2013, 577, p 64–72.

H.L. Huang, M.P. Liu, X.L. Wang, Y. Xing, Z.H. Jia et al., Atomic Scale Analysis of Hf-Containing Precipitates in an Al-Si-Mg-Hf Alloy, J. Alloy. Compd., 2018, 741, p 1070–1079.

X.L. Wang, Z.Q. Xie, H.L. Huang, Z.H. Jia, G. Yang, L. Gu and Q. Liu, Precipitation of (Si2-xAlx)Hf in the Al-Si-Mg-Hf Alloy, Microsc. Microanal., 2017, 23, p 724–729.

Y. Xing, Z.H. Jia, J.H. Li, L.P. Ding, H.L. Huang and Q. Liu, Microstructure and Mechanical Properties of Foundry Al-Si-Cu-Hf alloy, Mater. Sci. Eng. A, 2018, 722, p 197–205.

W.F. Miao and D.E. Laughlin, Effects of Cu Content and Pre aging on Precipitation Characteristics in Aluminum Alloy 6022, Metall. Mater. Trans. A, 1999, 3, p 361–371.

R. Chen, Q.Y. Xu, H.T. Guo, Z.Y. Xia, Q.F. Wu and B.C. Liu, Modeling the Precipitation Kinetics and Tensile Properties in Al-7Si-Mg cast aluminum alloys, Mater. Sci. Eng. A, 2017, 685, p 403–416.

R.X. Li, R.D. Li and Y.H. Zhao, Age-Hardening Behavior of cast Al–Si Base Alloy, Mater. Lett., 2004, 58, p 2096–2101.

M. Rahimian, S. Amirkhanlou, P. Blake and S. Ji, Nanoscale Zr-Containing Precipitates: a Solution for Significant Improvement of High-Temperature Strength in Al-Si-Cu-Mg Alloys, Mater. Sci. Eng. A, 2018, 721, p 328–338.

G.Y. Liu, P. Blake, S.X. Ji. Effect of Zr on the High Cycle Fatigue and Mechanical Properties of Al–Si–Cu–Mg Alloys at Elevated Temperatures. J. Alloy. Compd. 2019, 809, p 151795.

K.L. Fan, X.S. Liu, G.Q. He and H. Chen, Elevated Temperature Low Cycle Fatigue of a Gravity Casting Al-Si-Cu alloy used for Engine Cylinder Heads, Mater. Sci. Eng. A, 2015, 632, p 127–136.

D.A. Lados and D. Apelian, Relationships Between Microstructure and Fatigue Crack Propagation Paths in Al–Si–Mg Cast Alloys, Eng. Fract. Mech., 2008, 75, p 821–832.

U. De Francisco, N.O. Larrosa, M.J. Peel. Hydrogen Environmentally Assisted Cracking During Static Loading of AA7075 and AA7449. Mater. Sci. Eng. A 2019, p 138662.

H.L. Huang, Z.H. Jia, Y. Xing, X.L. Wang and Q. Liu, Microstructure of Al-Si-Mg Alloy with Zr/Hf Additions During Solidification and Solution Treatment, Rare Met., 2019, 38, p 1033–1042.

J.Y. Yao, D.A. Graham, B. Rinderer and M.J. Couper, A TEM Study of Precipitation in Al-Mg-Si Alloys, Micron, 2001, 32, p 865–870.

J. W. Martin, Precipitation Hardening: Theory and Applications, Butterworth-Heinemann, 2012.

L. Alyaldin, M.H. Abdelaziz, A.M. Samuel and F.H. Samuel, Effect of Ni and Mn Additions on the Ambient and High-Temperature Performance of Zr-Containing Al-Si-Cu-Mg-Based Alloys: Role of Precipitation Hardening, Int. J. Metal. Cast., 2019, 12, p 825–838.

M.H. Abdelaziz, Microstructural and Mechanical Characterization of Transition Elements-Containing Al-Si-Cu-Mg Alloys For Elevated-Temperature Applications, Université du Québec à Chicoutimi, PhD Diss., 2018.

M.H. Abdelaziz, H.W. Doty, S. Valtierra and F.H. Samuel, Static Versus Dynamic Thermal Exposure of Transition Elements-Containing Al-Si-Cu-Mg Cast Alloy, Mater. Sci. Eng. A, 2019, 739, p 499–512.

Acknowledgments

This work was supported by Science and Technology Development Project of Guangdong Academy of Science (Grant No. 2020GDASYL-20200103131), National Natural Science Foundation of China (Grant No. 51871035), Innovative Research Groups of the National Natural Science Foundation of China (Grant No. 51421001) and Foundation and Applied Foundation Research of Guangdong Province (Grant No. 2019A15151101153)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Huang, H., Hu, C., Song, D. et al. Microstructure Characteristics and Elevated-Temperature Tensile Properties of Al-7Si-0.3Mg Alloys with Zr and Hf Addition. J. of Materi Eng and Perform 30, 9059–9066 (2021). https://doi.org/10.1007/s11665-021-06080-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06080-w