Abstract

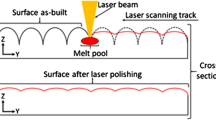

Directed energy deposition (DED) is one of the most used additive manufacturing processes for the fabrication of 3D-metal components. However, surface quality is not always within the limits required for most applications. Post-processing operations can overcome such a limitation. Laser polishing (LP) can be performed with the use of a same energy source and same gripping position, thus improving both surface roughness and functional characteristics (e.g., wettability). However, the literature lacks studies on the process parameters and their influence on roughness and wettability characteristics. This article investigates the influence of LP on surface roughness and wettability of AISI 316L SS produced by DED and proposes equations that predict surface roughness and remelted layer thickness (RLT) as a function of laser power (P). The surfaces were characterized by metallographic analysis, microhardness, surface roughness parameters (Sa, Sz, Sku, and Ssk), and contact angle. The results showed a reduction of up to 86% in Sa, and the Sz/Sa ratio as a P-function was correlated to a surface improvement. Sku and Ssk help to better characterize the surface, thus affecting its wettability. The RLT displayed a linear and P-dependent behavior. No alteration in the microstructure/microhardness was observed after the LP.

Similar content being viewed by others

References

N. Haghdadi, M. Laleh, M. Moyle and S. Primig, Additive Manufacturing of Steels: A Review of Achievements and Challenges, J. Mater. Sci., 2021, 56(1), p 64–107. https://doi.org/10.1007/s10853-020-05109-0

T.D. Ngo, A. Kashani, G. Imbalzano, K.T.Q. Nguyen and D. Hui, Additive Manufacturing (3D Printing ): A Review of Materials, Methods, Applications and Challenges, Compos. Part B, 2018, 143(February), p 172–196. https://doi.org/10.1016/j.compositesb.2018.02.012

ASTM, “Guide for Additive Manufacturing — Design — Directed Energy,” (West Conshohocken, PA.), 2019

M. Mehrpouya, A. Dehghanghadikolaei, B. Fotovvati, A. Vosooghnia, S.S. Emamian and A. Gisario, The Potential of Additive Manufacturing in the Smart Factory Industrial 4.0: A Review, Appl. Sci., 2019, 9(18), p 3865. https://doi.org/10.3390/app9183865

A. Bandyopadhyay, Y. Zhang and S. Bose, Recent Developments in Metal Additive Manufacturing, Curr. Opin. Chem. Eng., 2020, 28, p 96–104. https://doi.org/10.1016/j.coche.2020.03.001

T. DebRoy, H.L. Wei, J.S. Zuback, T. Mukherjee, J.W. Elmer, J.O. Milewski, A.M. Beese, A. Wilson-Heid, A. De and W. Zhang, Additive Manufacturing of Metallic Components—Process, Structure and Properties, Prog. Mater. Sci., 2018, 92, p 112–224. https://doi.org/10.1016/j.pmatsci.2017.10.001

ASTM International, ASTM F3187-16, Standard Guide for Directed Energy Deposition of Metals, 2016, p 1–22

K. Alrbaey, D.I. Wimpenny and A. Moroz, Electropolishing of Re-Melted SLM Stainless Steel 316L Parts Using Deep Eutectic Solvents: 3 9 3 Full Factorial Design, J. Mater. Eng. Perform., 2016, 25(7), p 2836–2846. https://doi.org/10.1007/s11665-016-2140-2

A. Huckstepp, Digital Alloys’ Guide to Metal Additive Manufacturing – Part 11: Surface Roughness, Digital Alloys, 2019

A.M.K. Hafiz, E.V. Bordatchev and R.O. Tutunea-Fatan, Influence of Overlap between the Laser Beam Tracks on Surface Quality in Laser Polishing of AISI H13 Tool Steel, J. Manuf. Process., 2012, 14(4), p 425–434. https://doi.org/10.1016/j.jmapro.2012.09.004

M. Marya, V. Singh, J.Y. Hascoet and S. Marya, A Metallurgical Investigation of the Direct Energy Deposition Surface Repair of Ferrous Alloys, J. Mater. Eng. Perform., 2018, 27(2), p 813–824. https://doi.org/10.1007/s11665-017-3117-5

A. Saboori, A. Aversa, G. Marchese, S. Biamino, M. Lombardi, and P. Fino, Application of Directed Energy Deposition-Based Additive Manufacturing in Repair, Appl. Sci., 2019, 9(16). https://doi.org/10.3390/app9163316

D. Ahn, H. Lee, J. Cho and D. Guk, Improvement of the Wear Resistance of Hot Forging Dies Using a Locally Selective Deposition Technology with Transition Layers, CIRP Ann. Manuf. Technol., 2016, 65(1), p 257–260. https://doi.org/10.1016/j.cirp.2016.04.013

M. Soshi, J. Ring, C. Young, Y. Oda and M. Mori, Innovative Grid Molding and Cooling Using an Additive and Subtractive Hybrid CNC Machine Tool, CIRP Ann. Manuf. Technol., 2017, 66(1), p 401–404. https://doi.org/10.1016/j.cirp.2017.04.093

P. Bajaj, A. Hariharan, A. Kini, P. Kürnsteiner, D. Raabe and E.A. Jägle, Steels in Additive Manufacturing: A Review of Their Microstructure and Properties, Mater. Sci. Eng. A, 2019, 2020, p 772. https://doi.org/10.1016/j.msea.2019.138633

A. Saboori, A. Aversa, G. Marchese, S. Biamino, M. Lombardi and P. Fino, Microstructure and Mechanical Properties of AISI 316L Produced by Directed Energy Deposition-Based Additive Manufacturing: A Review, Appl. Sci., 2020 https://doi.org/10.3390/app10093310

A. Azarniya, X.G. Colera, M.J. Mirzaali, S. Sovizi, F. Bartolomeu, M.K. St Weglowski, W.W. Wits, C.Y. Yap, J. Ahn, G. Miranda, F.S. Silva, H.R. Madaah Hosseini, S. Ramakrishna and A.A. Zadpoor, Additive Manufacturing of Ti–6Al–4V Parts through Laser Metal Deposition (LMD): Process, Microstructure, and Mechanical Properties, J. Alloys Compd., 2019, 804, p 163–191. https://doi.org/10.1016/j.jallcom.2019.04.255

A. Wiberg, J. Persson and J. Ölvander, Design for Additive Manufacturing—A Review of Available Design Methods and Software, Rapid Prototyp. J., 2019, 25(6), p 1080–1094. https://doi.org/10.1108/RPJ-10-2018-0262

Y. Kaynak and O. Kitay, The Effect of Post-Processing Operations on Surface Characteristics of 316L Stainless Steel Produced by Selective Laser Melting, Addit. Manuf., 2018, 2019(26), p 84–93. https://doi.org/10.1016/j.addma.2018.12.021

H. Hassanin, A. Elshaer, R. Benhadj-Djilali, F. Modica, and I. Fassi, Surface Finish Improvement of Additive Manufactured Metal Parts, Micro and Precision Manufacturing, K. Gupta, Ed., Springer, Cham, 2018, p 145–164. https://doi.org/10.1007/978-3-319-68801-5_7

L. Denti and A. Sola, On the Effectiveness of Different Surface Finishing Techniques on A357.0 Parts Produced by Laser-Based Powder Bed Fusion: Surface Roughness and Fatigue Strength, Metals (Basel), 2019, 9(12), p 1284. https://doi.org/10.3390/met9121284

F. Bruzzo, G. Catalano, A.G. Demir and B. Previtali, Surface Finishing by Laser Re-Melting Applied to Robotized Laser Metal Deposition, Opt. Lasers Eng., 2020, 2021, p 137. https://doi.org/10.1016/j.optlaseng.2020.106391

Y. Tian, D. Tomus, A. Huang and X. Wu, Melt Pool Morphology and Surface Roughness Relationship for Direct Metal Laser Solidification of Hastelloy X, Rapid Prototyp. J., 2020, 26(8), p 1389–1399.

Y. Zhao, J. Sun, J. Li, P. Wang, Z. Zheng, J. Chen and Y. Yan, The Stress Coupling Mechanism of Laser Additive and Milling Subtractive for FeCr Alloy Made by Additive –Subtractive Composite Manufacturing, J. Alloys Compd., 2018, 769, p 898–905. https://doi.org/10.1016/j.jallcom.2018.08.079

S. Greco, S. Kieren-Ehses, B. Kirsch and J.C. Aurich, Micro Milling of Additively Manufactured AISI 316L: Impact of the Layerwise Microstructure on the Process Results, Int. J. Adv. Manuf. Technol., 2021, 112(1–2), p 361–373. https://doi.org/10.1007/s00170-020-06387-3

O. Oyelola, P. Crawforth, R. M’Saoubi and A.T. Clare, Machining of Additively Manufactured Parts: Implications for Surface Integrity, Procedia CIRP, 2016, 45, p 119–122. https://doi.org/10.1016/j.procir.2016.02.066

J. Guo, M. Goh, Z. Zhu, X. Lee, M.L.S. Nai and J. Wei, On the Machining of Selective Laser Melting CoCrFeMnNi High-Entropy Alloy, Mater. Des., 2018, 153, p 211–220. https://doi.org/10.1016/j.matdes.2018.05.012

Y. Lu, G.F. Sun, Z.D. Wang, B.Y. Su, Y.K. Zhang and Z.H. Ni, The Effects of Laser Peening on Laser Additive Manufactured 316L Steel, Int. J. Adv. Manuf. Technol., 2020, 107(5–6), p 2239–2249. https://doi.org/10.1007/s00170-020-05167-3

M. Sugavaneswaran, A.V. Jebaraj, M.D.B. Kumar, K. Lokesh and A.J. Rajan, Enhancement of Surface Characteristics of Direct Metal Laser Sintered Stainless Steel 316L by Shot Peening, Surf. Interfaces, 2018, 12(May), p 31–40. https://doi.org/10.1016/j.surfin.2018.04.010

M. Salmi, J. Huuki and I.F. Ituarte, The Ultrasonic Burnishing of Cobalt-Chrome and Stainless Steel Surface Made by Additive Manufacturing, Prog. Addit. Manuf., 2017, 2(1–2), p 31–41. https://doi.org/10.1007/s40964-017-0017-z

J. Zhang, A. Chaudhari and H. Wang, Surface Quality and Material Removal in Magnetic Abrasive Finishing of Selective Laser Melted 316L Stainless Steel, J. Manuf. Process., 2019, 45(February), p 710–719. https://doi.org/10.1016/j.jmapro.2019.07.044

H. Yamaguchi, O. Fergani and P.Y. Wu, Modification Using Magnetic Field-Assisted Finishing of the Surface Roughness and Residual Stress of Additively Manufactured Components, CIRP Ann. Manuf. Technol., 2017, 66(1), p 305–308. https://doi.org/10.1016/j.cirp.2017.04.084

P. Tyagi, T. Goulet, C. Riso, R. Stephenson, N. Chuenprateep, J. Schlitzer, C. Benton and F. Garcia-Moreno, Reducing the Roughness of Internal Surface of an Additive Manufacturing Produced 316 Steel Component by Chempolishing and Electropolishing, Addit. Manuf., 2018, 2019(25), p 32–38. https://doi.org/10.1016/j.addma.2018.11.001

Y. Bai, C. Zhao, J. Yang, J.Y.H. Fuh, W.F. Lu, C. Weng and H. Wang, Dry Mechanical-Electrochemical Polishing of Selective Laser Melted 316L Stainless Steel, Mater. Des., 2020, 193, p 108840. https://doi.org/10.1016/j.matdes.2020.108840

D. Wang, Y. Liu, Y. Yang and D. Xiao, Theoretical and Experimental Study on Surface Roughness of 316L Stainless Steel Metal Parts Obtained through Selective Laser Melting, Rapid Prototyp. J., 2016, 22(4), p 706–716. https://doi.org/10.1108/RPJ-06-2015-0078

L. Giorleo, E. Ceretti and C. Giardini, Ti Surface Laser Polishing: Effect of Laser Path and Assist Gas, Procedia CIRP, 2015, 33, p 446–451. https://doi.org/10.1016/j.procir.2015.06.102

J. Kumstel, Laser Polishing of Metallic Freeform Surfaces by Using a Dynamic Laser Beam Preforming System, J. Laser Appl., 2021, 33, p 022020. https://doi.org/10.2351/1.5128459

B. Rosa, P. Mognol and J. Hascoët, Laser Polishing of Additive Laser Manufacturing Surfaces, J. Laser Appl., 2015, 27(S2), p S29102. https://doi.org/10.2351/1.4906385

J. Dos Santos Solheid, H.J. Seifert and W. Pfleging, Laser Surface Modification and Polishing of Additive Manufactured Metallic Parts, Procedia CIRP, 2018, 74, p 280–284. https://doi.org/10.1016/j.procir.2018.08.111

N. Islam, J. Schanz, D. Kolb and H. Riegel, Improvement of Surface Quality and Process Area Rate in Selective Laser Melting by Beam Oscillation Scan Technique, J. Mater. Eng. Perform., 2021 https://doi.org/10.1007/s11665-021-05665-9

T. Ermergen and F. Taylan, Review on Surface Quality Improvement of Additively Manufactured Metals by Laser Polishing, Arab. J. Sci. Eng., 2021 https://doi.org/10.1007/s13369-021-05658-9

S. Marimuthu, A. Triantaphyllou, M. Antar, D. Wimpenny, H. Morton and M. Beard, Laser Polishing of Selective Laser Melted Components, Int. J. Mach. Tools Manuf., 2015, 95, p 97–104. https://doi.org/10.1016/j.ijmachtools.2015.05.002

A. Temmler, D. Liu, J. Preußner, S. Oeser, J. Luo, R. Poprawe and J.H. Schleifenbaum, Influence of Laser Polishing on Surface Roughness and Microstructural Properties of the Remelted Surface Boundary Layer of Tool Steel H11, Mater. Des., 2020, 192, p 108689. https://doi.org/10.1016/j.matdes.2020.108689

L. Chen, B. Richter, X. Zhang, X. Ren and F.E. Pfefferkorn, Modification of Surface Characteristics and Electrochemical Corrosion Behavior of Laser Powder Bed Fused Stainless-Steel 316L after Laser Polishing, Addit. Manuf., 2019, 2020(32), p 101013. https://doi.org/10.1016/j.addma.2019.101013

F.E. Pfefferkorn, N.A. Duffie, J.D. Morrow and Q. Wang, Effect of Beam Diameter on Pulsed Laser Polishing of S7 Tool Steel, CIRP Ann. Manuf. Technol., 2014, 63(1), p 237–240. https://doi.org/10.1016/j.cirp.2014.03.055

L. Cao, S. Chen, M. Wei, Q. Guo, J. Liang, C. Liu and M. Wang, Effect of Laser Energy Density on Defects Behavior of Direct Laser Depositing 24CrNiMo Alloy Steel, Opt. Laser Technol., 2018, 2019(111), p 541–553. https://doi.org/10.1016/j.optlastec.2018.10.025

L. Chen, B. Richter, X. Zhang, K.B. Bertsch, D.J. Thoma and E. Pfefferkorn, A Effect of Laser Polishing on the Microstructure and Mechanical Properties of Stainless Steel 316L Fabricated by Laser Powder Bed Fusion, Mater. Sci. Eng. A, 2020, 2021(802), p 140579. https://doi.org/10.1016/j.msea.2020.140579

D. Zhang, J. Yu, H. Li, X. Zhou, C. Song and C. Zhang, Investigation of Laser Polishing of Four Selective Laser Melting Alloy Samples, Appl. Sci., 2020 https://doi.org/10.3390/app10030760

K.J. Kubiak, M.C.T. Wilson, T.G. Mathia and P. Carval, Wettability versus Roughness of Engineering Surfaces, Wear, 2011, 271, p 523–528. https://doi.org/10.1016/j.wear.2010.03.029

C. Ma, S. Bai, X. Peng and Y. Meng, Anisotropic Wettability of Laser Micro-Grooved SiC Surfaces, Appl. Surf. Sci., 2013, 284, p 930–935. https://doi.org/10.1016/j.apsusc.2013.08.055

S. Mukherjee, S. Dhara and P. Saha, Enhanced Corrosion, Tribocorrosion Resistance and Controllable Osteogenic Potential of Stem Cells on Micro-Rippled Ti6Al4V Surfaces Produced by Pulsed Laser Remelting, J. Manuf. Process., 2021, 65(March), p 119–133. https://doi.org/10.1016/j.jmapro.2021.03.023

J. Zhao, J. Guo, P. Shrotriya, Y. Wang and Y. Han, A Rapid One-Step Nanosecond Laser Process for Fabrication of Super- Hydrophilic Aluminum Surface, Opt. Laser Technol., 2019, 117(1038), p 134–141. https://doi.org/10.1016/j.optlastec.2019.04.015

D. Kwon, S. Wooh, H. Yoon and K. Char, Mechanoresponsive Tuning of Anisotropic Wetting on Hierarchically Structured Patterns, Langmuir, 2018, 34(16), p 4732–4738. https://doi.org/10.1021/acs.langmuir.8b00496

K.C. Yung, S.S. Zhang, L. Duan, H.S. Choy and Z.X. Cai, Laser Polishing of Additive Manufactured Tool Steel Components Using Pulsed or Continuous-Wave Lasers, Int. J. Adv. Manuf. Technol., 2019, 105(1–4), p 425–440. https://doi.org/10.1007/s00170-019-04205-z

A. Ascari, A.H.A. Lutey, E. Liverani and A. Fortunato, Laser Directed Energy Deposition of Bulk 316L Stainless Steel, Lasers Manuf. Mater. Process., 2020, 7(4), p 426–448. https://doi.org/10.1007/s40516-020-00128-w

H. Fayazfar, M. Salarian, A. Rogalsky, D. Sarker, P. Russo, V. Paserin and E. Toyserkani, A Critical Review of Powder-Based Additive Manufacturing of Ferrous Alloys: Process Parameters, Microstructure and Mechanical Properties, Mater. Des., 2018, 144, p 98–128. https://doi.org/10.1016/j.matdes.2018.02.018

H. Le, P. Penchev, A. Henrottin, D. Bruneel, V. Nasrollahi, J.A. Ramos-de-Campos and S. Dimov, Effects of Top-Hat Laser Beam Processing and Scanning Strategies in Laser Micro-Structuring, Micromachines, 2020, 11(2), p 1–17. https://doi.org/10.3390/mi11020221

A. Saboori, G. Piscopo, M. Lai, A. Salmi and S. Biamino, An Investigation on the Effect of Deposition Pattern on the Microstructure, Mechanical Properties and Residual Stress of 316L Produced by Directed Energy Deposition, Mater. Sci. Eng. A, 2020, 780, p 139179. https://doi.org/10.1016/j.msea.2020.139179

K.S.B. Ribeiro, F.E. Mariani and R.T. Coelho, A Study of Different Deposition Strategies in Direct Energy Deposition (DED) Processes, Procedia Manuf., 2020, 48, p 663–670. https://doi.org/10.1016/j.promfg.2020.05.158

G. Barragan, D. Rojas, J. Grass, F. Mariani and R. Coelho, Characterization and Optimization of Process Parameters for Directed Energy Deposition Powder-Fed Laser, System, 2021 https://doi.org/10.1007/s11665-021-05762-9

ASTM International, “Standard Test Method for Microindentation Hardness of Materials,” 2017, p 1–40, https://doi.org/10.1520/E0384-17

F. Rupp, R.A. Gittens, L. Scheideler, A. Marmur, B.D. Boyan, Z. Schwartz and J. Geis-gerstorfer, A Review on the Wettability of Dental Implant Surfaces I: Theoretical and Experimental Aspects, Acta Biomater., 2014, 10(7), p 2894–2906. https://doi.org/10.1016/j.actbio.2014.02.040

J. Yu, M. Rombouts and G. Maes, Cracking Behavior and Mechanical Properties of Austenitic Stainless Steel Parts Produced by Laser Metal Deposition, Mater. Des., 2013, 45, p 228–235. https://doi.org/10.1016/j.matdes.2012.08.078

M.A. Obeidi, E. McCarthy, B. O’Connell, I.U. Ahad and D. Brabazon, Laser Polishing of Additive Manufactured 316L Stainless Steel Synthesized by Selective Laser Melting, Mater. Basel., 2019 https://doi.org/10.3390/ma12060991

M.A. Obeidi, E. Mccarthy, L. Kailas and D. Brabazon, Laser Surface Texturing of Stainless Steel 316L Cylindrical Pins for Interference Fit Applications, J. Mater. Process. Tech., 2017, 2018(252), p 58–68. https://doi.org/10.1016/j.jmatprotec.2017.09.016

K. Hiroshi, T. Makoto and I. Kenji, Nanoindentation Hardness Test for Estimation of Vickers Hardness, Trans JWRI, 2006, 35(1), p 57–61.

E.S. Gadelmawla, M.M. Koura, T.M.A. Maksoud, I.M. Elewa, and H.H. Soliman, Roughness Parameters, J. Mater. Process. Technol., 2002, 123, p 133–145, https://doi.org/10.1016/S0924-0136(02)00060-2

D. Kubies, L. Himmlová, T. Riedel, E. Chánová, K. Balík, M.D.Ě Rová, J. Bártová and V. Pešáková, The Interaction of Osteoblasts With Bone-Implant Materials: 1, Effect Physicochem. Surf. Prop. Implant Mater., 2011, 8408, p 95–111. https://doi.org/10.33549/physiolres.931882

E. Ukar, A. Lamikiz, S. Martínez, I. Tabernero and L.N.L. De Lacalle, Roughness Prediction on Laser Polished Surfaces, J. Mater. Process. Tech., 2012, 212(6), p 1305–1313. https://doi.org/10.1016/j.jmatprotec.2012.01.007

R. Thomas, Characterization of Surface Roughness, Precis. Eng., 1981 https://doi.org/10.1016/0141-6359(81)90043-X

M.J.K. Lodhi, K.M. Deen, M.C. Greenlee-wacker and W. Haider, Additively Manufactured 316L Stainless Steel with Improved Corrosion Resistance and Biological Response for Biomedical Applications, Addit. Manuf., 2018, 2019(27), p 8–19. https://doi.org/10.1016/j.addma.2019.02.005

R. Wenzel, Resistance of Solid Surfaces to Wetting by Water, Indus. Eng. Chem., 1936, 28(8), p 988–994. https://doi.org/10.1021/ie50320a024

D. Bhaduri, P. Penchev, A. Batal, S. Dimov, S. Leung, S. Sten, U. Harrysson, Z. Zhang and H. Dong, Applied Surface Science Laser Polishing of 3D Printed Mesoscale Components, Appl. Surf. Sci., 2017, 405, p 29–46. https://doi.org/10.1016/j.apsusc.2017.01.211

Acknowledgments

The authors acknowledge the financial support of São Paulo Research Foundation (FAPESP)—Grant Numbers 2016/11309-0, 2019/10758-4, 2019/26362-2—and Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES)—Finance Code 001.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special topical focus in the Journal of Materials Engineering and Performance on Additive Manufacturing. The issue was organized by Dr. William Frazier, Pilgrim Consulting, LLC; Mr. Rick Russell, NASA; Dr. Yan Lu, NIST; Dr. Brandon D. Ribic, America Makes; and Caroline Vail, NSWC Carderock.

Rights and permissions

About this article

Cite this article

Souza, A.M., Ferreira, R., Barragán, G. et al. Effects of Laser Polishing on Surface Characteristics and Wettability of Directed Energy-Deposited 316L Stainless Steel. J. of Materi Eng and Perform 30, 6752–6765 (2021). https://doi.org/10.1007/s11665-021-05991-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05991-y