Abstract

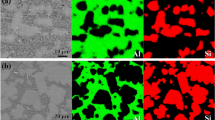

We developed a cold pressure-welding process for manufacturing Al-Cu plate butt joints and investigated the relationship between the interfacial microstructure and tensile properties. In the as-welded state, the grain sizes of Al and Cu were refined compared to those before welding. CuAl2 of thickness less than 150 nm was present at the interfacial layer, and Al and Cu were bonded via CuAl2. When the welded joint was annealed at 773 K for 7.2 ks, the total thickness of the intermetallic compound (IMC) layers increased with annealing temperature; layers of CuAl2 and mixed Al2Cu3+Al4Cu9+AlCu3 were formed from the Al side toward Cu. Interfacial fractures were confirmed in some welded joints when the total IMC layer thickness exceeded 4.3 μm; these fractures were observed at the Al-CuAl2 boundary. The growth of the IMC layers was dependent on the diffusion mechanism, and the calculated apparent activation energy was 99.7 kJ/mol.

Similar content being viewed by others

Data Availability

All data are available from the corresponding author on reasonable request.

References

M. Abbasi, A.K. Taheri and M.T. Salehi, Growth Rate of Intermetallic Compounds in Al/Cu Bimetal Produced by Cold Roll Welding Process, J. Alloys Compd., 2001, 319(1–2), p 233–241.

A. Abdollah-Zadeh, T. Saeid and B. Sazgari, Microstructural and Mechanical Properties of Friction Stir Welded Aluminum/Copper Lap Joints, J. Alloys Compd., 2008, 460(1–2), p 535–538.

M. Acarer, Electrical, Corrosion, and Mechanical Properties of Aluminum-Copper Joints Produced by Explosive Welding, J. Mater. Eng. Perform., 2012, 21, p 2375–2379.

H. Amani and M. Soltanieh, Intermetallic Phase Formation in Explosively Welded Al/Cu Bimetals, Metall. Mater. Trans. B., 2016, 47B, p 2524–2534.

M. Asemabadi, M. Sedighi and M. Honarpisheh, Investigation of Cold Rolling Influence on the Mechanical Properties of Explosive-Welded Al/Cu Bimetal, Mater. Sci. Eng. A., 2012, 558, p 144–149.

R. Balasundaram, V.K. Patel, S.D. Bhole and D.L. Chen, Effect of Zinc Interlayer on Ultrasonic Spot Welded Aluminum-to-Copper Joints, Mater. Sci. Eng A., 2014, 607, p 277–286.

C.Y. Chen, H.L. Chen and W.S. Hwang, Influence of Interfacial Structure Development on the Fracture Mechanism and Bond Strength of Aluminum/Copper Bimetal Plate, Mater. Trans., 2006, 47(4), p 1232–1239.

S. Chen, H. Dong, P. Li, S. Niu, L. Yu and H. Ji, Microstructure and Mechanical Property of Aluminum/Copper Dissimilar Friction Welded Joints, Weld J., 2017, 96, p 63–70.

C.Y. Chen and W.S. Hwang, Effect of Annealing on the Interfacial Structure of Aluminum-Copper Joints, Mater. Trans., 2007, 48(7), p 1938–1947.

T. Enjo, K. Ikeuchi and N. Akikawa, Diffusion Welding of Copper to Aluminum, J. Jpn. Weld. Soc., 1979, 48(10), p 32–37.

Y. Funamizu and K. Watanabe, Interdiffusion in the Al-Cu System, Trans. JIM., 1971, 12(3), p 147–152.

I. Galvão, R.M. Leal, A. Loureiro and D.M. Rodrigues, Material Flow in Heterogeneous Friction Stir Welding of Aluminum and Copper tin Sheets, Sci. Technol. Weld Joining., 2010, 15(8), p 654–660.

I. Galvão, J.C. Oliveira, A. Loureiro and D.M. Rodrigues, Formation and Distribution of Brittle Structures in Friction Stir Welding of Aluminum and Copper: Influence Of Shoulder Geometry, Intermetallics, 2012, 22, p 122–128.

Y. Guo, G. Liu, H. Jin, Z. Shi and G. Qiao, Intermetallic Phase Formation In Diffusion-Bonded Cu/Al Laminates, J. Mater. Sci., 2011, 46, p 2467–2473.

E.B. Hannech, N. Lamoudi, N. Benslim and B. Makhloufi, Intermetallic Formation in the Aluminum-Copper System, Surf. Rev. Lett., 2003, 10(4), p 677–683.

M. Honarpisheh, M. Asemabadi and M. Sedighi, Investigation of Annealing Treatment on the Interfacial Properties of Explosive-Welded Al/Cu/Al Multilayer, Mater. Des., 2012, 37, p 122–127.

F. Ji, S. Xue and W. Dai, Reliability Studies of Cu/Al Joints Brazed with Zn-Al-Ce Filler Metals, Mater. Des., 2012, 42, p 156–163.

F. Ji, S. Xue, J. Lou, Y. Lou and S. Wang, Microstructure and Properties of Cu/Al Joints Brazed with Zn-Al Filler Metals, Trans. Nonferrous Metals Soc. Chn., 2012, 22(2), p 281–287.

M. Kimura, Y. Inui, M. Kusaka, K. Kaizu and A. Fuji, Joining phenomena and Tensile Strength of Friction Welded Joint Between Pure Aluminum and Pure Copper, Mech. Eng. J., 2015, 2(1), p 1–14.

W.B. Lee, K.S. Bang and S.B. Jung, Effects of Intermetallic Compound on the Electrical and Mechanical Properties of Friction Welded Cu/Al Bimetallic Joints During Annealing, J. Alloys. Compd., 2005, 390(1–2), p 212–219.

X. Li, G. Zu, M. Ding, Y. Mu and P. Wang, Interfacial Microstructure and Mechanical Properties of Cu/Al Clad Sheet Fabricated by Asymmetrical Roll Bonding and Annealing, Mater. Sci. Eng. A., 2011, 529, p 485–491.

X.B. Li, G.Y. Zu and P. Wang, Microstructural Development and its Effects on Mechanical Properties of Al/Cu Laminated Composite, Trans. Nonferrous Metals Soc. Chn., 2015, 25, p 36–45.

Mao Z, Xie J, Wang A, Wang W, Ma D, Liu P. Effects of Annealing Temperature on the Interfacial Microstructure and Bonding Strength of Cu/Al Clad Sheets Produced by Twin-Roll Casting and Rolling. J. Mater. Process. Technol. 2020;285:116804.

K.P. Mehta and V.J. Badheka, Hybrid Approaches of Assisted Heating and Cooling for Friction Stir Welding of Copper to Aluminum Joints, J. Mater. Process. Technol., 2017, 239, p 336–345.

Nagasaki S, Hirabayashi M (2002) Binary Alloy Phase Diagram, AGNE Gijutsu Center, 27.

L. Pan, P. Li, X. Hao, J. Zhou and H. Dong, Inhomogeneity of Microstructure and Mechanical Properties in Radial Direction of Aluminum/Copper Friction Welded Joints, J. Mater. Process. Technol., 2018, 255, p 308–318.

T. Saeid, A. Abdollah-zadeh and B. Sazgari, Weldability and Mechanical Properties of Dissimilar Aluminum-Copper Lap Joints Made by Friction Stir Welding, J. Alloys Compd., 2010, 490(1–2), p 652–655.

M. Sahin, Joining of Aluminum and Copper Materials with Friction Welding, Int. J. Adv. Manuf. Technol., 2010, 49, p 527–534.

L.Y. Sheng, F. Yang, T.F. Xi, C. Lai and H.Q. Ye, Influence of Heat Treatment on Interface of Cu/Al Bimetal Composite Fabricated By Cold Rolling, Composites B., 2011, 42(6), p 1468–1473.

T. Solchenbach, P. Plapper and W. Cai, Electrical Performance of Laser Braze-Welded Aluminum-Copper Interconnects, J. Manuf. Proc., 2014, 16(2), p 183–189.

C.W. Tan, Z.G. Jiang, L.Q. Li, Y.B. Chen and X.Y. Chen, Microstructure Evolution and Mechanical Properties of Dissimilar Al-Cu Joints Produced by Friction Stir Welding, Mater Des., 2013, 51, p 466–473.

M. Weigl, F. Albert and M. Schmidt, Enhancing Ductility Of Laser-Welded Copper-Aluminum Connections by Using Adapted Filler Materials, Phys. Procedia., 2011, 12B, p 332–338.

H. Woźniak, The Results of the so far Performed Investigation of Al-Cu butt Cold Pressure Welding by the Method of Upsetting, Arch. Civil. Mech. Eng., 2009, 9(1), p 135–145.

C. Xia, Y. Li, U.A. Puchkov, S.A. Gerasimov and J. Wang, Microstructure and Phase Constitution Near The Interface of Cu/Al Vacuum Brazing Al-Si Filler Metal, Vacuum, 2008, 82(8), p 799–804.

Y. Xiao, H. Ji, M. Li and J. Kim, Ultrasound-Assisted Brazing of Cu/Al Dissimilar Metals Using a Zn-3Al Filler Metal, Mater. Des., 2013, 52, p 740–747.

P. Xue, B.L. Xiao and Z.Y. Ma, Effect of Interfacial Microstructure Evolution on Mechanical Properties and Fracture Behavior of Friction Stir-Welded Al-Cu Joints, Metall. Mater. Trans A., 2015, 46A, p 3091–3103.

P. Xue, B.L. Xiao, D.R. Ni and Z.Y. Ma, Enhanced Mechanical Properties Of Friction Stir Welded Dissimilar Al-Cu Joint by Intermetallic Compounds, Mater. Sci. Eng A., 2010, 527(21–22), p 5723–5727.

D. Zuo, S. Hu, J. Shen and Z. Xue, Intermediate Layer Characterization and Fracture Behavior of Laser-Welded Copper/Aluminum Metal Joints, Mater. Des., 2014, 58, p 357–362.

Acknowledgment

This work was financially supported by the Innovative Energy Conservation Technology Innovation Program of New Energy and Industrial Technology Development Organization (NEDO) (Grant Number 19101868-0). We would also like to thank Editage (wwweditage.com) for English language editing.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nishikawa, S., Arayashiki, T., Takahashi, M. et al. Effect of Interfacial Microstructure on Mechanical Properties of Cold Pressure-Welded Al-Cu Joints Subjected to Annealing. J. of Materi Eng and Perform 30, 7386–7396 (2021). https://doi.org/10.1007/s11665-021-05970-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05970-3