Abstract

Ti6Al4V is widely used as a metallic biomaterial and in cutting-edge fields of biomedicine that must comply with emerging technological demands such as smart wearable pieces and implantable electronic devices. In this work, we perform a duplex process where pure tantalum thin films were deposited over Ti6Al4V substrate by magnetron sputtering followed by a post-treatment consisting of plasma nitriding. Plasma nitrided Ta films exhibit improvement in wettability and increased roughness, both of which are attributed to the texturing of the surfaces. The RBS results plus SIMRA simulations allow to analyze the thin film stoichiometry and thickness variation according to the processes carried out. XRD spectra provided information of the nitrogen incorporation in tantalum, as a Ta containing phase was observed in plasma nitrided films. In summary, nitrogen-enriched tantalum films tailored by duplex process of sputtering/plasma nitriding fulfills important characteristics of quality coatings, synergistically.

Similar content being viewed by others

References

N. Tüten, D. Canadinc, A. Motallebzadeh, and B. Bal, Microstructure and Tribological Properties of TiTaHfNbZr High Entropy Alloy Coatings Deposited on Ti-6Al-4V Substrates, Intermetallics, 2019, 105, p 99–106

J.J. Jacobs, A.K. Skipor, L.M. Patterson, N.J. Hallab, W.G. Paprosky, J. Black, and J.O. Galante, Metal Release in Patients Who Have Had a Primary Total Hip Arthroplasty: A Prospective, Controlled, Longitudinal Study, J. Bone Jt. Surg. Ser. A, 1998, 80(10), p 1447–1458

B.D. Beake and T.W. Liskiewicz, Comparison of Nano-Fretting and Nano-Scratch Tests on Biomedical Materials, Tribol. Int., 2013, 63, p 123–131

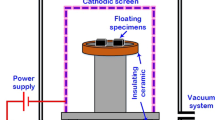

C.P. Fontoura, M.M. Rodrigues, C.S.C. Garcia, K. Dos Santos Souza, J.A.P. Henriques, J.E. Zorzi, M. Roesch-Ely, and C. Aguzzoli, Hollow Cathode Plasma Nitriding of Medical Grade Ti6Al4V: A Comprehensive Study, J. Biomater. Appl., 2020, 35(3), p 353–370

X. Yu, L. Tan, H. Yang, and K. Yang, Surface Characterization and Preparation of Ta Coating on Ti6Al4V Alloy, J. Alloys Compd., 2015, 644, p 698–703

O. Unal, E. Maleki, and R. Varol, Effect of Severe Shot Peening and Ultra-Low Temperature Plasma Nitriding on Ti-6Al-4V Alloy, Vacuum, 2018, 150, p 69–78

M.P. Fiorucci, A.J. López, and A. Ramil, Surface Modification of Ti6Al4V by Nanosecond Laser Ablation for Biomedical Applications, J. Phys. Conf. Ser., 2015, 605(1), p 012022

W.L. Lo, S.Y. Hsu, Y.C. Lin, S.Y. Tsai, Y.T. Lai, and J.G. Duh, Improvement of High Entropy Alloy Nitride Coatings (AlCrNbSiTiMo)N on Mechanical and High Temperature Tribological Properties by Tuning Substrate Bias, Surf. Coat. Technol., 2020, 401, p 126247

A.H. Ramezani, M.R. Hantehezadeh, M. Ghoranneviss, and E. Darabi, Corrosion Resistance Behavior of Nitrogen Ion-Implanted in Tantalum, Appl. Phys. A Mater. Sci. Process., 2016, 122(3), p 179

X.M. Zhang, Y. Li, Y.X. Gu, C.N. Zhang, H.C. Lai, and J.Y. Shi, Ta-Coated Titanium Surface with Superior Bacteriostasis and Osseointegration, Int. J. Nanomed., 2019, 14, p 8693–8706

A. Maho, S. Linden, C. Arnould, S. Detriche, J. Delhalle, and Z. Mekhalif, Tantalum Oxide/Carbon Nanotubes Composite Coatings on Titanium, and Their Functionalization with Organophosphonic Molecular Films: A High Quality Scaffold for Hydroxyapatite Growth, J. Colloid Interface Sci., 2012, 371(1), p 150–158

Y. Zhang, Y. Zheng, Y. Li, L. Wang, Y. Bai, Q. Zhao, X. Xiong, Y. Cheng, Z. Tang, Y. Deng, and S. Wei, Tantalum Nitride-Decorated Titanium with Enhanced Resistance to Microbiologically Induced Corrosion and Mechanical Property for Dental Application, PLoS ONE, 2015, 10(6), p e0130774

R. Li, Y. Qin, G. Liu, C. Zhang, H. Liang, Y. Qing, Y. Zhang, and K. Zhang, Tantalum Nitride Coatings Prepared by Magnetron Sputtering to Improve the Bioactivity and Osteogenic Activity for Titanium Alloy Implants, RSC Adv. R. Soc. Chem., 2017, 7(87), p 55408–55417

H.B. Nie, S.Y. Xu, S.J. Wang, L.P. You, Z. Yang, C.K. Ong, J. Li, and T.Y.F. Liew, Structural and Electrical Properties of Tantalum Nitride Thin Films Fabricated by Using Reactive Radio-Frequency Magnetron Sputtering, Appl. Phys. A Mater. Sci. Process., 2001, 73(2), p 229–236

J. An and Q.Y. Zhang, Structure, Hardness and Tribological Properties of Nanolayered TiN/TaN Multilayer Coatings, Mater. Charact., 2007, 58(5), p 439–446

S.-I. Baik and Y.-W. Kim, Microstructural Evolution of Tantalum Nitride Thin Films Synthesized by Inductively Coupled Plasma Sputtering, Appl. Microsc, 2020, 50(1), p 1–10

J. Nazon, J. Sarradin, V. Flaud, J.C. Tedenac and N. Fréty, Effects of Processing Parameters on the Properties of Tantalum Nitride Thin Films Deposited by Reactive Sputtering, J. Alloys Compd., 2008, 464(1–2), p 526–531

D.M. Mattox, Handbook of Physical Vapor Deposition (PVD) Processing, William Andrew, Norwich, 2007

W.-F. Wu, K.-L. Ou, C.-P. Chou, and C.-C. Wu, Effects of Nitrogen Plasma Treatment on Tantalum Diffusion Barriers in Copper Metallization, J. Electrochem. Soc., 2003, 150(2), p G83

C. Wang, T. Hisatomi, T. Minegishi, M. Nakabayashi, N. Shibata, M. Katayama, and K. Domen, Thin Film Transfer for the Fabrication of Tantalum Nitride Photoelectrodes with Controllable Layered Structures for Water Splitting, Chem. Sci. R. Soc. Chem., 2016, 7(9), p 5821–5826

A.H. Ramezani, S. Hoseinzadeh, and Z. Ebrahiminejad, Structural and Mechanical Properties of Tantalum Thin Films Ected by Nitrogen Ion Implantation, Mod. Phys. Lett. B, 2020, 34(15), p 2150008

A.C. Hee, Y. Zhao, S.S. Jamali, A. Bendavid, P.J. Martin, and H. Guo, Characterization of Tantalum and Tantalum Nitride Films on Ti6Al4V Substrate Prepared by Filtered Cathodic Vacuum Arc Deposition for Biomedical Applications, Surf. Coat. Technol., 2019, 365, p 24–32

A.H. Ramezani, S. Hoseinzadeh, and A. Bahari, The Effects of Nitrogen on Structure, Morphology and Electrical Resistance of Tantalum by Ion Implantation Method, J. Inorg. Organomet. Polym. Mater., 2018, 28(3), p 847–853

M. Peikert, E. Wieser, J.V. Borany, H. Reuther, K. Dittmar, and D. Gehre, Incorporation of Nitrogen in Thin Tantalum Films Using Plasma Immersion Ion Implantation, Surf. Coat. Technol., 2005, 200(7), p 2253–2259

M. Stavrev, D. Fischer, C. Wenzel, K. Drescher, and N. Mattern, Crystallographic and Morphological Characterization of Reactively Sputtered Ta, Ta-N and Ta-N-O Thin Films, Thin Solid Films, 1997, 307(1–2), p 79–88

H.C.M. Knoops, L. Baggetto, E. Langereis, M.C.M. van de Sanden, J.H. Klootwijk, F. Roozeboom, R.A.H. Niessen, P.H.L. Notten, and W.M.M. Kessels, Deposition of TiN and TaN by Remote Plasma ALD for Cu and Li Diffusion Barrier Applications, J. Electrochem. Soc., 2008, 155(12), p G287

M. Alishahi, F. Mahboubi, S.M. Mousavi Khoie, M. Aparicio, E. Lopez-Elvira, J. Méndez, and R. Gago, Structural Properties and Corrosion Resistance of Tantalum Nitride Coatings Produced by Reactive DC Magnetron Sputtering, RSC Adv., 2016, 6(92), p 89061–89072

M. Popović, M. Novaković, and N. Bibić, Structural Characterization of TiN Coatings on Si Substrates Irradiated with Ar Ions, Mater. Charact., 2009, 60(12), p 1463–1470

F. Fernández-Lima, E. Vigil, I. Zumeta, F.L. Freire, R. Prioli, and E. Pedrero, Rutherford Backscattering Spectrometry Analysis of TiO2 Thin Films, Mater. Charact., 2003, 50(2–3), p 155–160

H.P. Quiroz, M. Manso-Silván, A. Dussan, C. Busó-Rogero, P. Prieto, and F. Mesa, TiO2 and Co Multilayer Thin Films via DC Magnetron Sputtering at Room Temperature: Interface Properties, Mater. Charact., 2020, 163, p 110293

M. Mayer, SIMNRA, a Simulation Program for the Analysis of NRA, RBS and ERDA, AIP Conference Proceedings, 2008, p 541–544

N.W.M. Ritchie, Getting Started with NIST DTSA-II, Microsc. Today, 2011, 19(1), p 26–31

N.W.M. Ritchie, Spectrum Simulation in DTSA-II, Microsc. Microanal., 2009, 15(5), p 454–468

M.M. Rodrigues, C.P. Fontoura, A.E. Dotta Maddalozzo, L.M. Leidens, H.G. Quevedo, K. dos Santos Souza, J. da Silva Crespo, A.F. Michels, C.A. Figueroa, and C. Aguzzoli, Ti, Zr and Ta Coated UHMWPE Aiming Surface Improvement for Biomedical Purposes, Compos. Part B Eng., 2020, 189, p 107909

X. Jia, Wettability of Rough Polymer, Metal and Oxide Surfaces as Well as of Composite Surfaces, J. Adhes. Sci. Technol., 2008, 22(15), p 1893–1905

A. Žemaitis, A. Mimidis, A. Papadopoulos, P. Gečys, G. Račiukaitis, E. Stratakis, and M. Gedvilas, Controlling the Wettability of Stainless Steel from Highly-Hydrophilic to Super-Hydrophobic by Femtosecond Laser-Induced Ripples and Nanospikes, RSC Adv., 2020, 10(62), p 37956–37961

D. Xiong, Z. Gao, and Z. Jin, Friction and Wear Properties of UHMWPE against Ion Implanted Titanium Alloy, Surf. Coat. Technol., 2007, 201(15), p 6847–6850

M. Wang, Y. Wu, S. Lu, T. Chen, Y. Zhao, H. Chen, and Z. Tang, Fabrication and Characterization of Selective Laser Melting Printed Ti-6Al-4V Alloys Subjected to Heat Treatment for Customized Implants Design, Prog. Nat. Sci. Mater. Int., 2016, 26(6), p 671–677

Z. Ding, Y. Wang, Q. Zhou, Z. Ding, Y. Wu, Y. Zhu, W. Shi, and Q. He, The Preparation and Properties of Multilayer Cu-MTa2O5 Composite Coatings on Ti6Al4V for Biomedical Applications, Nanomaterials, 2019, 9(10), p 1498

R. Gabor, M. Doubkova, S. Gorosova, K. Malanik, M. Vandrovcova, L. Cvrcek, K. Drobikova, K. Mamulova Kutlakova, and L. Bacakova, Preparation of Highly Wettable Coatings on Ti-6Al-4V ELI Alloy for Traumatological Implants Using Micro-Arc Oxidation in an Alkaline Electrolyte, Sci. Rep., 2020, 10(1), p 19780

M. Echeverry-Rendón, O. Galvis, R. Aguirre, S. Robledo, J.G. Castaño, and F. Echeverría, Modification of Titanium Alloys Surface Properties by Plasma Electrolytic Oxidation (PEO) and Influence on Biological Response, J. Mater. Sci. Mater. Med., 2017, 28(11), p 1–14

R. Haarindraprasad, U. Hashim, S.C.B. Gopinath, M. Kashif, P. Veeradasan, S.R. Balakrishnan, K.L. Foo, P. Poopalan, and Y.K. Mishra, Low Temperature Annealed Zinc Oxide Nanostructured Thin Film-Based Transducers: Characterization for Sensing Applications, PLoS ONE, 2015, 10(7), p e0132755

S.V. Kamat, V. Puri, and R.K. Puri, The Effect of Film Thickness on the Structural Properties of Vacuum Evaporated Poly(3-Methylthiophene) Thin Films, ISRN Polym. Sci., 2012, 2012, p 1–8

M. Braun, Surface Analysis by RBS and NRA, Vacuum, 1984, 34(12), p 1045–1052

D. Krecar, M. Rosner, M. Draxler, P. Bauer, and H. Hutter, Low Energy RBS and SIMS Analysis of the SiGe Quantum Well, Appl. Surf. Sci., 2005, 252(1 SPEC. ISS.), p 123–126

H. Zhang, N. Guo, Y. Zhang, X. Ma, D. Gao, Q. Wang, Q. Lei, W. Zhang, and H. Shen, Measurement of Helium in ICF Pellet with External RBS System in Fudan University, Nucl. Instrum Methods Phys. Res. Sect B Beam Interact. Mater. Atoms, 2019, 450, p 337–341

R.M. Nagabharana, N. Kiran, P. Guha, B. Sundaravel, and U.M. Bhatta, Structural Characterization of Magnetron Sputtered ZnO Thin Films on Si(100) Using RBS Scanning and High Resolution Transmission Electron Microscopy Methods, Surf Interfaces, 2019, 15, p 239–243

I. Burducea, A.O. Mateescu, G. Mateescu, C. Ionescu, M. Straticiuc, L.S. Craciun, C.P. Lungu, G.O. Pompilian, and P.M. Racolt, AFM, RBS and Tribological Properties of WC/WS2 Nanostructures after 1.5 MeV Nb+ Implantation, Nucl. Instrum Methods Phys. Res. Sect B Beam Interact. Mater. Atoms, 2019, 450, p 357–360

S. Pinilla, T. Campo, J.M. Sanz, F. Márquez, and C. Morant, Highly Ordered Metal-Coated Alumina Membranes: Synthesis and RBS Characterization, Surf. Coatings Technol., 2019, 377, p 124883

M.S. Hussain, M. Mehmood, J. Ahmad, M.T. Tanvir, A.F. Khan, T. Ali, and A. Mahmood, RBS Depth Profiling and Optical Characterization of Multilayers of TiO 2 (20 Nm) and Ge (15 Nm), Mater. Chem. Phys., 2013, 139(1), p 17–26

C.D. Nascimento, E.G. Souza, C. Aguzzoli, and R.L. Cruz, Effects of Oxygen on the Resistivity in Au Thin Films with Ti-Al Adhesion Layer, J. Vac. Sci. Technol. B, 2019, 37(5), p 052202

R.E. Trentin, A.L. Bandeira, F. Cemin, M. Morales, C.L.G. Amorim, C. Aguzzoli, F. Alvarez, I.J.R. Baumvol, M.C.M. Farias, and C.A. Figueroa, Physicochemical, Structural, Mechanical, and Tribological Characteristics of Si3N4-MoS2 Thin Films Deposited by Reactive Magnetron Sputtering, Surf. Coat. Technol., 2014, 254, p 327–332

H. Schneidewind, T. Schüler, K.K. Strelau, K. Weber, D. Cialla, M. Diegel, R. Mattheis, A. Berger, R. Möller, and J. Popp, The Morphology of Silver Nanoparticles Prepared by Enzyme-Induced Reduction, Beilstein J. Nanotechnol., 2012, 3(1), p 404–414

M. Ueda, G.F. Gomes, K.G. Kostov, H. Reuther, C.M. Lepienski, P.C. Soares, O. Takai, and M.M. Silva, Results from Experiments on Hybrid Plasma Immersion Ion Implantation/Nitriding Processing of Materials, Brazilian J. Phys., 2004, 34(4 B), p 1632–1637

E. Roliński, J. Arner, and G. Sharp, Negative Effects of Reactive Sputtering in an Industrial Plasma Nitriding, J. Mater. Eng. Perform., 2005, 14(3), p 343–350

Y. Seo, S. Lee, S.H.C. Baek, W.S. Hwang, H.Y. Yu, S.H. Lee, and B.J. Cho, The Mechanism of Schottky Barrier Modulation of Tantalum Nitride/Ge Contacts, IEEE Electron Device Lett., 2015, 36(10), p 997–1000

J. Cheng, J. Xu, L.L. Liu, and S. Jiang, Electrochemical Corrosion Behavior of Ta2n Nanoceramic Coating in Simulated Body Fluid, Materials (Basel), 2016, 9(9), p 772

L. Li, H. Hei, Y. Wang, K. Zheng, Y. Ma, J. Gao, B. Zhou, Z. He, J. Zong, S. Yu, and B. Tang, Microstructure and Properties of Ta Coatings on the 3Y-TZP Ceramic Fabricated by Plasma Alloying Technique, J. Alloys Compd., 2019, 805, p 1135–1143

A. Ramos-Masana and C. Colominas, Evaluation of DC-MS and HiPIMS TiB2 and TaN Coatings as Diffusion Barriers against Molten Aluminum: An Insight into the Wetting Mechanism, Surf. Coat. Technol., 2019, 375, p 171–181

K.L. Ou, W.F. Wu, C.P. Chou, S.Y. Chiou, and C.C. Wu, Improved TaN Barrier Layer against Cu Diffusion by Formation of an Amorphous Layer Using Plasma Treatment, J. Vac. Sci. Technol. B Microelectron. Nanom. Struct., 2002, 20(5), p 2154–2161

H.C. Chung and C.P. Liu, Effect of Crystallinity and Preferred Orientation of Ta2N Films on Diffusion Barrier Properties for Copper Metallization, Surf. Coat. Technol., 2006, 200(10 SPEC. ISS.), p 3122–3126

J.C. Tsao, C.P. Liu, H.C. Fang, and Y.L. Wang, How Tantalum Proceeds Phase Change on Tantalum Nitride Underlayer with Sequential Ar Plasma Treatment, Mater. Chem. Phys., 2013, 137(3), p 689–693

S.M. Aouadi and M. Debessai, Optical Properties of Tantalum Nitride Films Fabricated Using Reactive Unbalanced Magnetron Sputtering, J. Vac. Sci. Technol. A Vac. Surf. Films, 2004, 22(5), p 1975–1979

Acknowledgments

The authors are thankful to the following divisions at the University of Caxias do Sul: Graduate Program in Materials Science and Engineering (PPGMAT), the Biotechnology Institute (IB), and Microscopy Center (LCMic), and also the Ion Implantation Laboratory at the Institute of Physics (IF) at the Federal University of Rio Grande do Sul. CPF and AEDM are CAPES fellows. MMR, JSC, CAF, and CA are CNPq fellows. This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brasil (CAPES)—Finance Code—001, and INCT-INES (CNPq).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special topical focus in the Journal of Materials Engineering and Performance on Surface Engineering. The issue was organized by Dr. M. K. Banerjee, Malaviya National Institute of Technology, Jaipur.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Padilha Fontoura, C., Dotta Maddalozzo, A.E., Machado Rodrigues, M. et al. Nitrogen Incorporation into Ta Thin Films Deposited over Ti6Al4V: A Detailed Material and Surface Characterization. J. of Materi Eng and Perform 30, 4094–4102 (2021). https://doi.org/10.1007/s11665-021-05879-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05879-x