Abstract

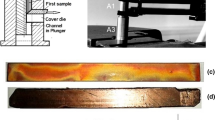

Different degrees of strain occur during the manufacturing of CP800 torsion beams, leading to a decrease in mechanical properties and the formation of residual tensile stress in local regions. Thus, the performance and fatigue resistance of torsion beams are negatively affected. Prestrained CP800 steel samples with tensile strains of 0 or 7% are annealed from 400 to 700 °C in the present study. The mechanical properties of the above samples are measured by tensile testing, and the microstructure is characterized by scanning electron microscopy, transmission electron microscopy, x-ray stress meter and atom probe tomography. The results show that after proper annealing at 575-650 °C, the product of the strength and elongation of the CP800 samples increases to 14.2-16.1 GPa%, which is higher than that of the original hot-rolled sheet (13.3 GPa%). This improvement is attributed to the change in strengthening mechanisms. During the proper annealing process, a large number of dispersive carbides emerge in the matrix of the prestrained samples. The precipitation strengthening which has less damage to ductility has been introduced into the matrix, while the solution strengthening is weakened.

Similar content being viewed by others

Change history

16 April 2021

A Correction to this paper has been published: https://doi.org/10.1007/s11665-021-05729-w

References

J.H. Schmitt and T. Iung, New Developments of Advanced High-Strength Steels for Automotive Applications, C. R. Phys., 2018, 19(8), p 641–656.

X.X. Li, A. Ramazani, U. Prahl, and W. Bleck, Quantification of Complex-Phase Steel Microstructure by Using Combined EBSD and EPMA Measurements, Mater. Charact., 2018, 142, p 179–186.

E. Dias, L. Horimoto, and M. Pereira, Microstructural Characterization of CP Steel Used in Automotive Industry, Mater. Sci. Forum, 2014, 775–776, p 141–145.

K.H. Hu, L.B. Pan, L.J. Li, and J.P. Tian, Latest Progress in Development of Cold-Rolled Complex Phase Steel, Metall. Eng., 2016, 03(01), p 34–43.

Z. Liu, L.H. Lang, S.W. Ruan, M. Zhang, F.L. Lv, and J. Qi, Effect of Internal Pressure Assisted on Hydroforming for CP800 High-Strength Steel Torsion Beam, J. Braz. Soc. Mech. Sci. Eng., 2019, 41(2), p 90.

H.F. Sun, K. Wei, X.J. Yang, Z. Xiao, and Y.Z. Wu, Effects of Pre-strain and Annealing on the Fatigue Properties of Complex Phase Steel CP800, Int. J. Fatigue, 2020, 131, p 105364.

S. Kim, T. Song, H. Sung, and S. Kim, Effect of Pre-Straining on High Cycle Fatigue and Fatigue Crack Propagation Behaviors of Complex Phase Steel, Met. Mater. Int., 2020 https://doi.org/10.1007/s12540-020-00751-4

J.Z. Xue, Z.Z. Zhao, Z.Y. Mo, H. Li, H.H. Wu, W.L. Xiong, and D. Tang, Effect of Microstructural Evolution and Fractographic Properties on Hole Expandability of Hot Rolling Complex Phase Steel with Different Coiling Temperature, Mater. Res. Express, 2019, 6(11), p 116564.

M. Różański, M. Morawiec, A. Grajcar, and S. Stano, Modified Twin-Spot Laser Welding of Complex Phase Steel, Arch. Metall. Mater., 2016, 61(4), p 1999–2008.

A. Graux, S. Cazottes, D.D. Castro et al., Design and Development of Complex Phase Steels with Improved Combination of Strength and Stretch-Flange Ability, Metals, 2020, 10(6), p 824.

B. Hutchinson, J. Hagstrom, O. Karlsson, D. Lindell, M. Tornberg, F. Lindberg, and M. Thuvander, Microstructures and Hardness of As-Quenched Martensites (0.1–0.5%C), Acta Mater., 2011, 59(14), p 5845–5858.

Y. Xiao, W. Li, H.S. Zhao, X.W. Lu, and X.J. Jin, Investigation of Carbon Segregation during Low Temperature Tempering in a Medium Carbon Steel, Mater. Charact., 2016, 117, p 84–90.

R.K.W. Marceau, P. Choi, and D. Raabe, Understanding the Detection of Carbon in Austenitic High-Mn Steel Using Atom Probe Tomography, Ultramicroscopy, 2013, 132, p 239–247.

S.C. Kennett, G. Krauss, and K.O. Findley, Prior Austenite Grain Size and Tempering Effects on the Dislocation Density of Low-C Nb-Ti Microalloyed Lath Martensite, Scr. Mater., 2015, 107, p 123–126.

A. Jilg and T. Seifert, Temperature Dependent Cyclic Mechanical Properties of a Hot Work Steel After Time and Temperature Dependent Softening, Mater. Sci. Eng. A, 2018, 721, p 96–102.

T. Wen, X. Hu, Y. Song, D. Yan, and L. Rong, Effect of Tempering Temperature on Carbide and Mechanical Properties in a Fe-Cr-Ni-Mo High-Strength Steel, Acta Metall. Sin., 2014, 50(4), p 447–453.

Y. Zhang, D. Zhan, X. Qi, and Z. Jiang, Effect of Tempering Temperature on the Microstructure and Properties of Ultrahigh-Strength Stainless Steel, J. Mater. Sci. Technol., 2019, 35(7), p 1240–1249.

Z.X. Yuan, S.H. Song, J. Liu, and L.Q. Weng, Role of Pre-strain in Age Hardening of a Niobium-Microalloyed Steel, Mater. Lett., 2006, 59(3), p 2048–2051.

Y. Wang, J. Sun, T. Jiang, Y. Sun, S. Guo, and Y. Liu, A Low-Alloy High-Carbon Martensite Steel with 2.6 GPa Tensile Strength and Good Ductility, Acta Mater., 2018, 158, p 247–256.

Acknowledgments

This work was supported by the State Key Laboratory of Advanced Special Steel, Shanghai Key Laboratory of Advanced Ferrometallurgy and the Science and Technology Commission of Shanghai Municipality (No. 19DZ2270200).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original version of this article was revised: The graphic presented for Fig. 2 in this article as originally published was incorrect and has since been replaced.

Rights and permissions

About this article

Cite this article

Pei, Y., Jiang, Z. & Min, Y. Improving the Mechanical Properties of Prestrained CP800 Steel by Annealing-Induced Carbides. J. of Materi Eng and Perform 30, 3388–3396 (2021). https://doi.org/10.1007/s11665-021-05582-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05582-x