Abstract

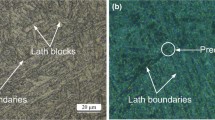

The evolution of the microstructure and mechanical properties of P91 steel during heat treatments at different cooling speeds during the normalization stage was investigated. Results showed that normalized martensite with high hardness and strength was obtained over a wide range of cooling rates (higher than 200 °C/h) during the normalization stage of P91 steel. Within this cooling rate range, twin martensite gradually generated as the cooling rate decreased, which enhanced the brittleness of the normalized P91 steel. When the cooling rate was decreased to 25 °C/h, the P91 steel exhibited completely annealed microstructures consisting mainly of bulk α-Fe grains, with the formation of continuous M23C6 carbides at the grain boundaries. As a result, the annealed P91 steel had poor hardness and strength, as well as demonstrating increased brittleness. Notably, after tempering, the hardness and strength of normalized martensite were greatly weakened, while the toughness of tempered martensite greatly increased. After the tempering process, the continuous M23C6 GBs in the completely annealed P91 steel partly dissolved, which also remarkably enhanced the toughness.

Similar content being viewed by others

References

S.S. Wang, D.L. Peng, L. Chang et al., Enhanced Mechanical Properties Induced by Refined Heat Treatment for 9Cr-0.5Mo-1.8W Martensitic Heat Resistant steel, Mater. Des., 2013, 50, p 174–180.

A. Chatterjee, A. Moitra, A.K. Bhaduri et al., Effect of Heat Treatment on Ductile–Brittle Transition Behaviour of 9Cr-1Mo Steel, Procedia Engineering, 2014, 86, p 287–294.

P. Yan, Z. Liu, H. Bao et al., Effect of Normalizing Temperature on the Strength of 9Cr-3W-3Co Martensitic Heat Resistant Steel, Mater. Sci. Eng. A, 2014, 597, p 148–156.

P. Yan, Z. Liu, H. Bao et al., Effect of Tempering Temperature on the Toughness of 9Cr-3W-3Co Martensitic Heat Resistant Steel, Mater. Des., 2014, 54, p 874–879.

N. Saini, C. Pandey, M.M. Mahapatra et al., A Comparative Study of Ductile–Brittle Transition Behavior and Fractography of P91 and P92 steel, Eng. Fail. Anal., 2017, 81, p 245–253.

C. Pandey, M.M. Mahapatra, P. Kumar et al., Study on Effect of Double Austenitization Treatment on Fracture Morphology Tensile Tested Nuclear Grade P92 Steel, Eng. Fail. Anal., 2019, 96, p 158–167.

T. Karthikeyan, M.K. Dash, Ravikirana et al., Effect of Prior-Austenite Grain Refinement on Microstructure, Mechanical Properties and Thermal Embrittlement of 9Cr-1Mo-0.1C Steel, J. Nucl. Mater., 2017, 494, p 260–277.

A. Chatterjee, D. Chakrabarti, A. Moitra et al., Effect of Normalization Temperatures on Ductile–Brittle Transition Temperature of a Modified 9Cr-1Mo steel, Mater. Sci. Eng. A, 2014, 618, p 219–231.

X. Zhang, Y. Zeng, W. Cai et al., Study on the Softening Mechanism of P91 Steel, Mater. Sci. Eng. A, 2018, 728, p 63–71.

C. Pandey, A. Giri and M.M. Mahapatra, Evolution of Phases in P91 Steel in Various Heat Treatment Conditions and Their Effect on Microstructure Stability and Mechanical Properties, Mater. Sci. Eng. A, 2016, 664, p 58–74.

B.K. Choudhary, K.B.S. Rao, S.L. Mannan et al., Influence of Prior Thermal Ageing on Tensile Deformation and Fracture Behaviour of Forged Thick Section 9Cr-1Mo Ferritic Steel, J. Nucl. Mater., 1999, 273(3), p 315–325.

B.K. Choudhary, K.B.S. Rao and S.L. Mannan, Effects of Strain Rate and Temperature on Tensile Deformation and Fracture Behaviour of Forged Thick Section 9Cr-1Mo Ferritic Steel, Int. J. Press. Vessels Pip., 1994, 58(2), p 151–160.

B.K. Choudhary, S. Saroja, K.B.S. Rao et al., Creep-Rupture Behavior of Forged, Thick Section 9Cr-1Mo Ferritic Steel, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 1999, 30(11), p 2825–2834.

T. Karthikeyan, M.K. Dash, S. Saroja et al., Evaluation of Interface Boundaries in 9Cr-1Mo Steel After Thermal and Thermomechanical Treatments, Metall. Mater. Trans. A, 2013, 44(4), p 1673–1685.

K.-N. Jang, T.-K. Kim and K.-T. Kim, The Effect of Cooling Rates on Carbide Precipitate and Microstructure of 9CR-1MO Oxide Dispersion Strengthened (ODS) Steel, Nucl. Eng. Technol., 2019, 51, p 249–256.

H. Xu, Z. Lu, D. Wang et al., Microstructure Refinement and Strengthening Mechanisms of a 9Cr Oxide Dispersion Strengthened Steel by Zirconium Addition, Nucl. Eng. Technol., 2017, 49(1), p 178–188.

K.R. Ham, The determination of dislocation densities in thin films, Phil. Mag., 1961, 6(69), p 1183–1184.

C. Du, Q. Pan, S. Chen et al., Effect of Rolling on the Microstructure and Mechanical Properties of 6061-T6 DS-FSW Plate, Mater. Sci. Eng. A, 2020, 772, p 138692.

C.G. Panait, Z.-L. Anna, T. Koziel et al., Evolution of Dislocation Density, Size of Subgrains and MX-Type Precipitates in a P91 Steel During Creep and During Thermal Ageing at 600 C for more than 100000 h, Mater. Sci. Eng. A, 2010, 527(16–17), p 4062–4069.

Y.Z. Shen, S.H. Kim, C.H. Han et al., TEM Investigations of MN Nitride Phases in a 9% Chromium Ferritic/Martensitic Steel with Normalization Conditions for Nuclear Reactors, J. Nucl. Mater., 2009, 384(1), p 48–55.

C. Liu, D. Zhang, Y. Liu et al., Investigation on the Precipitation Behavior of M3C Phase in T91 Ferritic Steels, Nucl. Eng. Des., 2011, 241, p 2411–2415.

W.B. Jones, C.R. Hills and D.H. Polonis, Microstructural Evolution of Modified 9Cr-lMo Steel, Metall. Trans. A, 1991, 22A, p 1049–1058.

C.J. Hamelin, O. Muránsky, M.C. Smith et al., Validation of a Numerical Model Used to Predict Phase Distribution and Residual Stress in Ferritic Steel Weldments, Acta Mater., 2014, 75, p 1–19.

Du. Jiang Xizhi, N.M. Chengchao and L. Junjian, Effect of Beam Offset on the Microstructure and Mechanical Properties of 201SS-Q235 Self-Fusion LBW Joint, J. Manuf. Process., 2019, 47, p 297–309.

W. Yi-Tong, Z. Yu-Guang, X. Xiao-Feng et al., Superior Mechanical Properties Induced by the Interaction Between Dislocations and Precipitates in the Electro-Pulsing Treated Al-Mg-Si Alloys, Mater. Sci. Eng. A, 2018, 735, p 154–161.

A. Chauhan, F. Bergner, A. Etienne et al., Microstructure Characterization and Strengthening Mechanisms of Oxide Dispersion Strengthened (ODS) Fe-9%Cr and Fe-14%Cr Extruded Bars, J. Nucl. Mater., 2017, 495, p 6–19.

X. Wang, Q. Xu, S. Yu, H. Liu, L. Hu and Y. Ren, Laves-Phase Evolution During Aging in fine Grained Heat-Affected Zone of a Tungsten-Strengthened 9% Cr Steel Weldment, J. Mater. Process. Technol., 2015, 219, p 60–69.

R.R. Shen, V. Ström and P. Efsing, Spatial Correlation Between Local Misorientation Sand Nanoindentation Hardness in Nickel-Base Alloy, Mater. Sci. Eng. A, 2016, 674, p 171–177.

J. Jiang, T.B. Britton and A.J. Wilkinson, Evolution of Dislocation Density Distributions in Copper During Tensile Deformation, Acta Mater., 2013, 61(19), p 7227–7239.

X. Ma, C. Huang, J. Moering et al., Mechanical Properties of Copper/Bronze Laminates: Role of Interfaces, Acta Mater., 2016, 116, p 43–52.

J.A. Muñoz, M. Avalos and R.E. Bolmaro, Heterogeneity of Strain Path, Texture and Microstructure Evolution of AA6063-T6 Processed by Equal Channel Angular Sheet Extrusion (ECASE), J. Alloys Compd., 2018, 768, p 349–357.

Acknowledgments

The authors would like to express their gratitude for projects supported by the National Natural Science Foundation of China (51574181 and 51374153) and Supported by Sichuan Science and Technology Program (2018JY0668). The help from Meng Ruan of Wuhan University was also appreciated.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ni, M., Wang, J., Liu, J. et al. Microstructure and Mechanical Properties of P91 Steel during Heat Treatment: The Effect of the Cooling Speed during the Normalization Stage. J. of Materi Eng and Perform 30, 2329–2340 (2021). https://doi.org/10.1007/s11665-021-05534-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05534-5