Abstract

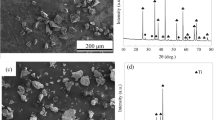

In this work, TiC/Ti5Si3/Ti3SiC2 composite coatings were fabricated by plasma spraying using Ti-SiC-graphite powders. The effect of SiC content on the microstructure, mechanical and tribological properties of the composite coatings was investigated. Results show that the as-sprayed composite coatings are mainly composed of TiC, Ti5Si3 and Ti3SiC2 phases. The composite coatings share a heterogeneous structure with a good bonding interface between layers. With the increase in SiC content, the hardness and fracture toughness of the composite coatings first decrease and then increase. The maximum hardness of 1195 HV0.2 and fracture toughness of 2.37 MPa \(\cdot\) m1/2 are obtained for 3Ti-0.5SiC-C coating. The mass loss of the composite coatings first increases and then decreases with the increase in SiC content, coupling with a friction coefficient of 0.4-0.5. The wear mechanism of the composite coatings shows a combination of adhesive, abrasive and oxidation wear.

Similar content being viewed by others

References

Z.M. Sun, Progress in Research and Development on MAX Phases: A Family of Layered Ternary Compounds, Int. Mater. Rev., 2011, 56(3), p 143–166.

Z.F. Zhang, Z.M. Sun, H. Hashimoto et al., Application of Pulse Discharge Sintering (PDS) Technique to Rapid Synthesis of Ti3SiC2 from Ti/Si/C Powders, J. Eur. Ceram. Soc., 2002, 22, p 2957–2961.

M.C. Peng, X.L. Shi, Z.W. Zhu et al., Facile Synthesis of Ti3SiC2 Powder by High Energy Ball-Milling and Vacuum Pressureless Heat-Treating Process From Ti-TiC-SiC-Al Powder Mixtures, Ceram. Int., 2012, 38, p 2027–2033.

M.A. El Saeed, F.A. Deorsola and R.M. Rashad, Optimization of the Ti3SiC2 MAX Phase Synthesis, Int. J. Refract. Met. Hard. Mater., 2012, 35, p 127–131.

N.C. Ghosh and S.P. Harimkar, Phase Analysis and Wear Behavior of In-Situ Spark Plasma Sintered Ti3SiC2, Ceram. Int., 2013, 39, p 6777–6786.

Y.M. Luo, W. Pan, S.Q. Li et al., Synthesis and Mechanical Properties of In-Situ Hot-Pressed Ti3SiC2 Polycrystals, Ceram. Int., 2002, 28, p 227–230.

N.F. Gao, Y. Miyamoto and D. Zhang, Dense Ti3SiC2 Prepared by Reactive HIP, J. Mater Sci., 1999, 34(18), p 4385–4392.

W. Jeitschko and H. Nowotny, Die Kristallstructur von Ti3SiC2-Ein Neuer Komplxcarbid-Typ, Monatshefte Für Chemie Und Verwandte Teile Anderer Wissenschaften, 1967, 98, p 2401–2406.

R. Pampuch, J. Lis, J. Piekarczyk et al., Ti3SiC2-Based Materials Produced by Self-Propagating High Temperature Synthesis and Ceramic Processing, J. Mater. Synth. Process., 1993, 1, p 93–100.

N.F. Gao, J.T. Li, D. Zhang et al., Rapid Synthesis of Dense Ti3SiC2 by Spark Plasma Sintering, J. Eur. Ceram. Soc., 2002, 22, p 2365–2370.

Z.F. Zhang, Z.M. Sun, H. Hashimoot et al., A New Synthesis Reaction of Ti3SiC2 Through Pulse Discharge Sintering Ti/SiC/TiC Powder, Scripta Mater., 2001, 45, p 1461–1467.

C. Li, S. Yan, F.Y. Zhang et al., Fabrication and Characterization of Micro-laminated TiC-Ti5Si3-Ti3SiC2 Composite Coatings by Atmosphere Plasma Spraying, Vacuum, 2019, 161, p 14–20.

Y.L. Zhang, H. Hu, P.F. Zhang et al., SiC/ZrB2-SiC-ZrC Multilayer Coating for Carbon/Carbon Composites Against Ablation, Surf. Coat. Technol., 2016, 300, p 1–9.

V. Pasumarthi, Y. Chen, S.R. Bakshi et al., Reaction Synthesis of Ti3SiC2 Phase in Plasma Sprayed Coating, J. Alloys Compd., 2009, 484, p 113–117.

F.A. Meng, B.Y. Liang and M.Z. Wang, Investigation of Formation Mechanism of Ti3SiC2 by Self-propagating High-Temperature Synthesis, Int. J. Refract. Met., 2013, 41, p 152–161.

L.H. Yu, H.Z. Dong and J.H. Xu, Influence of C Content on Microstructure Mechanical Properties and Friction and Wear Properties of TiWCN Composite Films, Acta Metall. Sin., 2014, 50, p 1350–1356.

C.L. Yeh and Y.G. Shen, Effects of TiC Addition on Formation of Ti3SiC2 by Self-propagating High-Temperature Synthesis, J. Alloys Compd., 2008, 458, p 286–291.

L.J. Wang, J. Wan, C. Qin et al., Effect of Starting SiC Particle Size on In Situ Fabrication of Ti5Si3/TiC Composites, Mater. Sci. Eng., A, 2006, 425(1–2), p 219–224.

H.Y. Sun, X. Kong, Z.Z. Yi et al., The Difference of Synthesis Mechanism Between Ti3SiC2 and Ti3AlC2 Prepared from Ti/M/C (M=Al or Si) Elemental Powders by SHS Technique, Ceram. Int., 2014, 40, p 12977–12981.

Y. Zou, Z.M. Sun, H. Hashimoto et al., Reaction Mechanism in Ti-SiC-C Powder Mixture During Pulse Discharge Sintering, Ceram. Int., 2010, 36, p 1027–1031.

C. Li, F.Y. Zhang, J.N. He et al., Microstructure Evolution and Mechanical Properties of Reactive Plasma Sprayed Ti3SiC2-Ti5Si3-TiC Composite Coatings, Mater. Chem. Phys., 2020, 254, p 123495.

X. Sun, J.H. Huang, J. Yang et al., Microstructure Evolution and Mechanical Properties of In-Situ Bimodal TiC/Fe Coatings Prepared by Reactive Plasma Spraying, Ceram. Int., 2019, 45, p 5848–5857.

Y.L. Liu, J.X. Chen and Y.C. Zhou, Effect of Ti5Si3 on Wear Properties of Ti3Si(Al)C2, J. Eur. Ceram. Soc., 2009, 29, p 3379–3385.

J.N. He, F.Y. Zhang, P.B. Mi et al., Microstructure and Wear Behavior of Nano C-rich TiCN Coatings Fabricated by Reactive Plasma Spraying with Ti-Graphite Powders, Surf. Coat. Technol., 2016, 305, p 215–222.

P.B. Mi, J.N. He, Y.F. Qin et al., Nanostructure Reactive Plasma Sprayed TiCN Coating, Surf. Coat. Technol., 2017, 309, p 1–5.

D. Zois, A. Lekatou and M. Vardavoulias, A Microstructure and Mechanical Property Investigation on Thermally Sprayed Nanostructured Ceramic Coatings Before and After a Sintering Treatment, Surf. Coat. Technol., 2009, 204(1–2), p 15–27.

L.L. Shaw, D. Goberman, R.M. Ren et al., The Dependency of Microstructure and Properties of Nanostructured Coatings on Plasma Spray Conditions, Surf. Coat. Technol., 2000, 130(1), p 1–8.

Z.L. Xu, J.J. Kang, H.D. Wang et al., Effect of Particle Character of Supersonic Plasma Sprayed NiCr-Cr3C2 on Coating Property, Mater. Sci. Eng. Powder Metall., 2015, 20(2), p 230–236.

F.Y. Zhang, J.N. He, K. Chen et al., Microstructure Evolution and Mechanical Properties of TiCN-Cr Nano/Micro Composite Coatings Prepared by Reactive Plasma Spraying, Appl. Surf. Sci., 2018, 427, p 905–914.

H.J. Zhao, F.F. Guo, L.Y. Zhu et al., The Effect of Cu Addition on the Crystallization Behavior and Tribological Properties of Reactive Plasma Sprayed TiCN-Cu Coatings, Ceram. Int., 2020, 46, p 8344–8351.

Acknowledgments

The authors gratefully acknowledge National Natural Science Foundation of China (Grant No. 51872073 and 51701062), Natural Science Foundation of Tianjin (Grant No.16JCQNJC03500).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, C., Zhang, F., Zhao, L. et al. Effect of SiC Content on Microstructure and Tribological Properties of Plasma Sprayed TiC/Ti5Si3/Ti3SiC2 Composite Coatings. J. of Materi Eng and Perform 30, 2147–2158 (2021). https://doi.org/10.1007/s11665-021-05529-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05529-2