Abstract

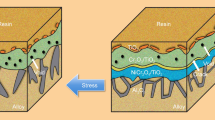

The grain refinement behavior in superalloys has been identified for a long time, while its exact underlying mechanism remains to be explored. In this study, transmission electron microscope and electron backscatter diffraction technique were employed to investigate the fundamental mechanism governing the process of grain refinement for as-cast superalloys GH4720LI. The results show that grain refinement highly depends on the distributions of γ′ precipitates. In γ + γ′ two-phase region, γ′ precipitates could promote the dislocation multiplication, hinder the dislocation motion and lead to the formation of high-density dislocation substructure. Hence, the sub-boundaries and high-angle grain boundaries (HABs) are formed resulting from the gradual transformation of the dislocation substructures. In this process, the new grains are developed by quasi-continuous dynamic recrystallization (quasi-CDRX) and discontinuous dynamic recrystallization (DDRX). In addition, strain rate has little influence on grain size and DRX behavior at high strain rate and low temperature. While in γ single-phase region, the dislocation within grains is partly consumed through continuous original boundary migration (COBM) at 0.01 s−1. Moreover, in some deformed grains which are expected to possess high dislocation density, new grains can be formed by DDRX. With the strain rate increasing, the process of COBM was suppressed while DDRX was promoted. Therefore, the main dynamic softening mechanism of alloy is DDRX under the high temperature and high strain rate.

Similar content being viewed by others

References

F.F. Liu, J.Y. Chen, J.X. Dong, M.C. Zhang, and Z.H. Yao, The Hot Deformation Behaviors of Coarse, Fine and Mixed Grain for Udimet 720Li Superalloy, Mater. Sci. Eng. A, 2016, 651, p 102–115

H. Monajati, F. Zarandi, M. Jahazi, and S. Yue, Strain Induced γ′ Precipitation in Nickel Base Superalloy Udimet 720 Using a Stress Relaxation Based Technique, Scripta Mater., 2005, 52, p 771–776

H. Monajati, M. Jahazi, R. Bahrami, and S. Yue, The Influence of Heat Treatment Conditions on γ′ Characteristics in Udimet 720, Mater. Sci. Eng. A, 2004, 373, p 286–293

B. Wang, S.H. Zhang, and M. Cheng, Dynamic Recrystallization Mechanism of Inconel 690 Superalloy during Hot Deformation at High Strain Rate, J. Mater. Eng. Perform., 2013, 22(8), p 2382–2388

A. Amiri, M.H. Sadeghi, and G.R. Ebrahimi, Characterization of Hot Deformation Behavior of AMS 5708 Nickel-Based Superalloy Using Processing Map, J. Mater. Eng. Perform., 2013, 22(12), p 3940–3945

Y.H. Liu, Y. Wu, J.W. Yu, J. Ju et al., Temperature-Dependent Deformation Mechanisms and Microstructural Degradation of a Polycrystalline Nickel-Based Superalloy, J. Alloys Compd., 2019, 775, p 181–192

L. Wang, F. Liu, J.J. Cheng, Q. Zuo, and C.F. Chen, Hot Deformation Characteristics and Processing Map Analysis for Nickel-Based Corrosion Resistant Alloy, J. Alloys Compd., 2015, 623, p 69–78

L. Li, L.M. Shen, G. Proust, and C.K.S. Moy, Three-Dimensional Crystal Plasticity Finite Element Simulation of Hot Compressive Deformation Behaviors of 7075 Al alloy, J. Mater. Eng. Perform., 2015, 24(3), p 1294–1304

H.J. McQueen and C.A.C. Imbert, Dynamic Recrystallization: Plasticity Enhancing Structural Development, J. Alloys Compd., 2004, 378, p 35–43

Y.Q. Ning, Z.K. Yao, M.W. Fu, and H.Z. Guo, Dynamic Recrystallization of the Hot Isostatically Pressed P M Superalloy FGH409, Mater. Sci. Eng. A, 2010, 527, p 6968–6974

S.S. Satheesh Kumar, T. Raghu, P.P. Bhattacharjee, G. Appa Rao et al., Work Hardening Characteristics and Microstructural Evolution during Hot Deformation of a Nickel Superalloy at Moderate Strain Rates, J. Alloys Compd., 2017, 709, p 394–409

L. Xu, L. Chen, G.J. Chen, and M.Q. Wang, Hot Deformation Behavior and Microstructure Analysis of 25Cr3Mo3NiNb Steel during Hot Compression Tests, Vacuum, 2018, 147, p 8–17

E.X. Pu, W.J. Zheng, Z.G. Song, H. Feng et al., Hot Deformation Characterization of Nickel-Based Superalloy UNS10276 Through Processing Map and Microstructural Studies, J. Alloys Compd., 2017, 694, p 617–631

L.F. Nie, L.W. Zhang, Z. Zhu, and W. Xu, Constitutive Modeling of Dynamic Recrystallization Kinetics and Processing Maps of Solution and Aging FGH96 Superalloy, J. Mater. Eng. Perform., 2013, 22(12), p 3728–3734

Y.L. Cai, C.G. Tian, G.L. Zhang, G.M. Han et al., Influence of γ′ Precipitates on the Critical Strain and Localized Deformation of Serrated Flow in Ni-Based Superalloys, J. Alloys Compd., 2017, 690, p 707–715

B.C. Xie, H. Yu, T. Sheng, and Y.H. Xiong, DDRX and CDRX of an As-Cast Nickel-Based Superalloy during Hot Compression at γ′ Sub-/Super-Solvus Temperatures, J. Alloys Compd., 2019, 803, p 16–29

Z.P. Wan, L.X. Hu, Y. Sun, and T. Wang, Hot Deformation Behavior and Processing Workability of a Ni-Based Alloy, J. Alloys Compd., 2018, 769, p 367–375

F.L. Li, R. Fu, F.J. Yin, D. Feng, H.Z. Wang, G. Du, and Y. Feng, Impact of γ′(Ni3(Al, Ti)) Phase on DRX of a Ni-Based Disk Superalloy during Isothermal Compression, J. Alloys Compd., 2017, 693, p 1076–1082

Y.Q. Ning, Z.K. Yao, M.W. Fu, and H.Z. Guo, Recrystallization of the Hot Isostatic Pressed Nickel-Base Superalloy FGH4096: I. Microstructure and Mechanism, Mater. Sci. Eng. A, 2011, 528, p 8065–8070

M. Pérez, C. Dumont, O. Nodin, and S. Nouveau, Impact of Forging Direction on the Recrystallization Behaviour of Nickel Base Superalloy AD730 Billet Material at Subsolvus Temperatures, Mater. Charact., 2018, 146, p 169–181

Z.P. Wan, L.X. Hu, Y. Sun, T. Wang, and Z. Li, Microstructure Evolution and Dynamic Softening Mechanisms during High-Temperature Deformation of a Precipitate Hardening Ni-Based Superalloy, Vacuum, 2018, 155, p 585–593

H. Monajati, A.K. Taheri, M. Jahazi, and S. Yue, Deformation Characteristics of Isothermally Forged UDIMET 720 Nickel-Base Superalloy, Metall. Mater. Trans. A, 2005, 36, p 895–905

M.R. Daymond, M. Preuss, and B. Clausen, Evidence of Variation in Slip MODE in a Polycrystalline Nickel-Base Superalloy with Change in Temperature from Neutron Diffraction Strain Measurements, Acta Mater., 2007, 55, p 3089–3102

J.X. Dong, L.H. Li, H.Y. Li, M.C. Zhang, and Z.H. Yao, Effect of Extent of Homogenization on the Hot Deformation Recrystallization of Superalloy Ingot in Cogging Process, Acta Mater. Sinica, 2015, 51, p 1207–1218

R. Radis, M. Schaffer, M. Albu, G. Kothleitner, P. Pölt, and E. Kozeschnik, Multimodal size Distributions of γ′ Precipitates during Continuous Cooling of UDIMET 720 Li, Acta Mater., 2009, 57, p 5739–5747

J. Mao, V.L. Keefer, K.M. Chang, and D. Furrer, An Investigation on Quench Cracking Behavior of Superalloy Udimet 720LI, Using Fracture Mechanics Approach, J. Mater. Eng. Perform., 2000, 9, p 204–214

Z.P. Wan, L.X. Hu, Y. Sun et al., Effect of Solution Treatment on Microstructure and Tensile Properties of a U720LI, Ni-Based Superalloy, Vacuum, 2018, 156, p 248–255

N. Stanford and M.R. Barnett, Effect of Particles on the Formation of Deformation Twins in a Magnesium-Based Alloy, Mater. Sci. Eng. A, 2009, 516, p 226–234

M. Hradilová, F. Montheillet, A. Fraczkiewicz, C. Desrayaud, and P. Lejček, Effect of Ca-Addition on Dynamic Recrystallization of Mg-Zn Alloy during Hot Deformation, Mater. Sci. Eng. A, 2013, 580, p 217–226

M.J. Luton and C.M. Sellars, Dynamic Recrystallization in Nickel and Nickel Iron Alloys during High Temperature Deformation, Acta Metall., 1969, 17, p 1033–1043

R. Le Gall and J.J. Jonas, Solute Drag Effects during the Dynamic Recrystallization of Nickel, Acta Mater., 1999, 47, p 4365–4374

W. Gao, A. Belyakov, H. Miura, and T. Sakai, Dynamic Recrystallization of Copper Polycrystals with Different Purities, Mater. Sci. Eng. A, 1999, 265, p 233–239

M. Rout, R. Ranjan, S.K. Pal, and S.B. Singh, EBSD Study of Microstructure Evolution during Axisymmetric Hot Compression of 304LN Stainless Steel, Mater. Sci. Eng. A, 2018, 711, p 378–388

T. Sakai and J.J. Jonas, Overview No. 35 Dynamic Recrystallization: Mechanical and Microstructural Considerations, Acta Metall., 1984, 32, p 189–209

Acknowledgment

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, X., Jiang, Z., Wan, Z. et al. Effect of Hot Deformation Parameters on Grain Refinement of an As-Cast Ni-Based Superalloy. J. of Materi Eng and Perform 29, 6343–6354 (2020). https://doi.org/10.1007/s11665-020-05135-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05135-8