Abstract

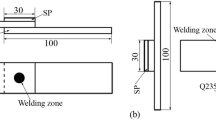

In order to improve the joining performance between aluminum alloy and steel, a method termed resistance projection-plug welding was tried to weld steel to aluminum alloy. The microstructure and properties of the joint obtained by this method under various welding parameters were analyzed. Scanning electron microscopy studies of the interfacial microstructures revealed that a reaction layer, consisting of Fe2Al5 adjacent to steel and FeAl3 adjacent to aluminum alloy, is formed in the interface outside the nugget. The maximum tensile shear and cross-tension loads of the joint reached 6.92 and 4.13 kN, respectively, in comparison with 5.0 and 1.4 kN, respectively, for resistance spot welding with a cover plate. The results revealed that the resistance projection-plug welding is an effective method for welding steel and aluminum alloys.

Similar content being viewed by others

References

H. Zhao, G. Zhang, Q. Zhang, C. Zhang, and Y. Li, Joining Mechanism and Mechanical Properties of Metallic Bump Assisted Weld-Bonded (MBaWB) Joints of AA6061-T6 and Bare DP590, J. Manuf. Process., 2020, 50, p 204–215

Y. Zhang and D. Sun, Microstructures and Mechanical Properties of Steel/Aluminum Alloy Joints Welded by Resistance Spot Welding, J. Mater. Eng. Perform., 2017, 26(6), p 2649–2662

S. Meco, S. Ganguly, S. Williams, and N. McPherson, Effect of Laser Processing Parameters on the Formation of Intermetallic Compounds in Fe-Al Dissimilar Welding, J. Mater. Eng. Perform., 2014, 23(9), p 3361–3370

H. Xia, C. Tan, L. Li, and N. Ma, In Situ SEM Observations of Fracture Behavior of Laser Welded-Brazed Al/Steel Dissimilar Joint, J. Mater. Eng. Perform., 2018, 27(9), p 1047–1057

R. Qiu, H. Shi, K. Zhang, Y. Tu, C. Iwamoto, and S. Satonaka, Interfacial Characterization of Joint Between Mild Steel and Aluminum Alloy Welded by Resistance Spot Welding, Mater. Charact., 2010, 61(7), p 684–688

J.S. Kim, I.J. Kim, and Y.G. Kim, Optimization of Welding Current Waveform for Dissimilar Material with DP590 and Al5052 by Delta-Spot Welding Process, J. Mech. Sci. Technol., 2016, 30(6), p 2713–2721

Y. Che, L. Wang, D. Sun, H. Li, and W. Geng, Microstructures and Mechanical Properties of Resistance Spot-Welded Steel/Aluminum Alloy Joints with Process Tapes, J. Mater. Eng. Perform., 2018, 27(10), p 5532–5544

D. Sun, Y. Zhang, Y. Liu, X. Gu, and H. Li, Microstructures and Mechanical Properties of Resistance Spot Welded Joints of 16Mn Steel and 6063-T6 Aluminum Alloy with Different Electrodes, Mater. Des., 2016, 109, p 596–598

W. Zhang, D. Sun, L. Han, and Y. Li, Optimised Design of Electrode Morphology for Novel Dissimilar Resistance Spot Welding of Aluminium Alloy and Galvanised High Strength Steel, Mater. Des., 2015, 85, p 461–470

R. Qiu, S. Satonaka, and C. Iwamoto, Effect of Interfacial Reaction Layer Continuity on the Tensile Strength of Resistance Spot Welded Joints between Aluminum Alloy and Steels, Mater. Des., 2009, 30, p 3686–3689

I. Ibrahim, R. Ito, T. Kakiuchi, Y. Uematsu, K. Yun, and C. Matsuda, Fatigue Behaviour of Al/Steel Dissimilar Resistance Spot Welds Fabricated Using Al-Mg Interlayer, Sci. Technol. Weld. Join., 2016, 21(3), p 223–233

T. Watanabe, Y. Doi, A. Yanagisawai, and S. Konuma, Resistance Spot Welding of Mild Steel to Al-Mg Alloy, Q. J. Jpn. Weld. Soc., 2005, 23(3), p 491–495

J. Chen, X. Yuan, Z. Hua, T. Li, K. Wu, and C. Li, Improvement of Resistance-Spot-Welded Joints for DP 600 Steel and A5052 Aluminum Alloy with Zn Slice Interlayer, J. Manuf. Process., 2017, 30, p 396–405

W. Zhang, D. Sun, L. Han, and D. Liu, Interfacial Microstructure and Mechanical Property of Resistance Spot Welded Joint of High Strength Steel and Aluminium Alloy with 4047 AlSi12 Interlayer, Mater. Des., 2014, 57, p 186–194

G. Zhang, H. Zhao, X. Xu, G. Qiu, Y. Li, and Z. Lin, Metallic Bump Assisted Resistance Spot Welding (MBaRSW) of AA6061-T6 and Bare DP590: Part II-Joining Mechanism and Joint Property, J. Manuf. Process., 2019, 44, p 19–27

R. Qiu, N. Wang, H. Shi, L. Cui, L. Hou, and K. Zhang, Joining Steel to Aluminum Alloy by Resistance Spot Welding with A Rivet, Int. J. Mater. Res., 2015, 106(1), p 60–65

Z. Ling, Y. Li, Z. Luo, Y. Feng, and Z. Wang, Resistance Element Welding of 6061 Aluminum Alloy to Uncoated 22MnMoB Boron Steel, Mater. Manuf. Process., 2016, 31(16), p 2174–2180

Z. Ling, Y. Li, Z. Luo, S. Aon, Z. Yin, Y. Gu, and Q. Chen, Microstructure and Fatigue Behavior of Resistance Element Welded Dissimilar Joints of DP780 Dual-Phase Steel to 6061-T6 Aluminum Alloy, Int. J. Adv. Manuf. Technol., 2017, 92, p 1923–1931

M. Lou, Y. Li, Y. Wang, B. Wang, and X. Lai, Influence of Resistance Heating on Self-Piercing Riveted Dissimilar Joints of AA6061-T6 and Galvanized DP590, J. Mater. Process. Technol., 2014, 214, p 2119–2126

J.P. Oliveira, K. Ponder, E. Brizes, T. Abke, A.J. Ramirez, and P. Edwards, Combining Resistance Spot Welding and Friction Element Welding for Dissimilar Joining of Aluminum to High Strength Steels, J. Mater. Process. Technol., 2019, 273, p 116–192

X. Fang and F. Zhang, Hybrid Joining of A Modular Multi-Material Body-in-White Structure, J. Mater. Process. Technol., 2020, 275, p 116351

S. Satonaka, K. Kaieda, and S. Okamoto, Prediction of Tensile-Shear Strength of Spot Welds Based on Fracture Modes, Welding in the World, 2004, 48(5/6), p 39–45

R. Qiu, C. Iwamoto, and S. Satonaka, Interfacial Microstructure and Strength of Steel/Aluminum Alloy Joints Welded by Resistance Spot Welding with Cover Plate, J. Mater. Process. Technol., 2009, 209, p 4186–4193

J. Chen, Z. Feng, H.P. Wang, B.E. Carlson, T. Brown, and D. Sigler, Multi-Scale Mechanical Modeling of Al-Steel Resistance Spot Welds, Mater. Sci. Eng., A, 2018, 735, p 145–153

Acknowledgments

The authors gratefully acknowledge funding from the Natural Science Foundation of China (Grant No. 51875177) and the International Cooperation Project of Henan Province (Grant No. 182102410066).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ren, K., Qiu, R., Ma, H. et al. Joining Aluminum Alloy to Steel by Resistance Projection-Plug Welding. J. of Materi Eng and Perform 29, 4087–4094 (2020). https://doi.org/10.1007/s11665-020-04893-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04893-9