Abstract

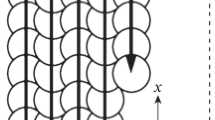

Atomic diffusion behavior and interface waveform characteristics and formation mechanism during laser shock welding were investigated by using a molecular dynamics (MD) model and smooth particle hydrodynamics (SPH) modeling. The MD simulation showed that the diffusion coefficient of Al atom was larger than that of the Ni atom. Ni atom is easily diffused deeply into the Al lattice during impact welding. The SPH simulation showed that the wavelength and amplitude of the welding interface increased with loading speed, and SPH simulations at different loading speeds demonstrated that the movement direction of the Ni wave peak is the same as the welding direction, whereas the movement direction of the Al wave peak is opposite to the welding direction. The effective plastic strain and temperature were mainly distributed at the interface waveform. The shear stress of the composite and substrate foil is in opposite direction near the collision point, and the pressure near the collision point was as high as about 10 GPa. Energy-dispersive spectroscopy line scanning analysis showed the presence of a 2.5-μm-thick element diffusion layer at the wavy interface between Al and Ni, verifying the element diffusion between Al and Ni in the MD simulation.

Similar content being viewed by others

Reference

S. Hirose, T. Itoh, M. Makita, S. Fujii, S. Arai, K. Sasaki, and H. Saka, Defect structure of deformed Fe2A15 intermetallic compound, Intermetallics, 2003, 11(7), p 633–642

M. Kimura, A. Fuji, Y. Konno, S. Itoh, and Y.C. Kim, Investigation of fracture for friction welded joint between pure nickel and pure aluminium with post-weld heat treatment, Mater. Des., 2014, 57, p 503–509

K. Yu, H.Q. Xiong, Y.L. Dai, F. Teng, S.F. Fan, X.Y. Qiao, and L. Wen, Bonding process and application properties of an Al-Ni layer composite sheet for lithium-ion battery packaging, Rare Metal Mater. Eng., 2016, 45(5), p 1100–1105

S. Kumai, M. Watanabe, and K.Y. Feng, Microstructure and joint strength of similar and dissimilar lap joints fabricated by several advanced solid-state welding methods, Mater. Sci. Forum, 2010, 654–656, p 596

A. Stern, V. Shribman, A. Ben-Artzy, and M. Aizenshtein, Interface phenomena and bonding mechanism in magnetic pulse welding, J. Mater. Eng. Perform., 2014, 23(10), p 3449–3458

S.Y. Yang and J.W. Bao, Microstructure and properties of 5083 Al/1060 Al/AZ31 composite plate fabricated by explosive welding, J. Mater. Eng. Perform., 2018, 27(3), p 1177–1184

X. Wang, C.X. Gu, Y.Y. Zheng, Z.B. Shen, and H.X. Liu, Laser shock welding of aluminum/aluminum and aluminum/copper plates, Mater. Des., 2014, 56, p 26–30

X. Wang, F. Li, T. Huang, X.J. Wang, and H.X. Liu, Experimental and numerical study on the laser shock welding of aluminum to stainless steel, Opt. Lasers Eng., 2019, 115, p 74–85

S.D. Chen, F.J. Ke, M. Zhou, and Y.L. Bai, Atomistic investigation of the effects of temperature and surface roughness on diffusion bonding between Cu and Al, Acta Mater., 2007, 55(9), p 3169–3175

S.P. Kiselev and V.I. Mali, Numerical and experimental modeling of jet formation during a high-velocity oblique impact of metal plates, Combust. Explos. Shock Waves, 2012, 48(2), p 214–225

S.Y. Chen, Z.W. Wu, K.X. Liu, X.J. Li, N. Luo, and G.X. Lu, Atomic diffusion behavior in Cu-Al explosive welding process, J. Appl. Phys., 2013, 113(4), p 044901

T.T. Zhang, W.X. Wang, J. Zhou, X.Q. Cao, R.S. Xie, and Y. Wei, Molecular dynamics simulations and experimental investigations of atomic diffusion behavior at bonding interface in an explosively welded Al/Mg alloy composite plate, Acta Metall. Sin. Engl. Lett., 2017, 30(10), p 983–991

X. Wang, Y.Y. Zheng, H.X. Liu, Z.B. Shen, Y. Hu, W. Li, Y.Y. Gao, and C. Guo, Numerical study of the mechanism of explosive/impact welding using smoothed particle hydrodynamics method, Mater. Des., 2012, 35, p 210–219

S. Plimpton, Fast parallel algorithms for short-range molecular dynamics, J. Comput. Phys., 1995, 117(1), p 1–19

S.D. Chen, A.K. Soh, and F.J. Ke, Molecular dynamics modeling of diffusion bonding, Scr. Mater., 2005, 52(11), p 1135–1140

D.J. Evans and B.L. Holian, The Nose–Hoover thermostat, J. Chem. Phys., 1985, 83(8), p 4069

Ansys 17.1 Autodyn User’s Manual

A. Turgutlu, S.T.S. Al-Hassani, and M. Akyurt, Experimental investigation of deformation and jetting during impact spot welding, Int. J. Impact Eng., 1995, 16(5), p 789–799

G.R. Johnson, W.H. Cook, A constitutive model and data for metals subjected to large strains high strain rates and high temperatures, in Proceedings of the 7th International Symposium on Ballistics (1983), pp. 541–547

C.D. Wu, T.H. Fang, and C.C. Wu, Effect of temperature on welding of metallic nanowires investigated using molecular dynamics simulations, Mol. Simul., 2016, 42(2), p 131–137

A.A.A. Mousavi, S.J. Burley, and S.T.S. Al-Hassani, Simulation of explosive welding using the Williamsburg equation of state to model low detonation velocity explosives, Int. J. Impact Eng., 2005, 31(6), p 719–734

X.Z. Guo, Y.N. Ma, K. Jin, H. Wang, J. Tao, and M.Y. Fan, Effect of stand-off distance on the microstructure and mechanical properties of Ni/Al/Ni laminates prepared by explosive bonding, J. Mater. Eng. Perform., 2017, 26(9), p 4235–4244

H.X. Liu, S. Gao, Z. Yan, L.Y. Li, C. Li, X.Q. Sun, C.F. Sha, Z.B. Shen, Y. Ma, and X. Wang, Investigation on a novel laser impact spot welding, Metals, 2016, 6, p 8

X. Wang, M. Shao, H. Jin, H. Tang, and H.X. Liu, Laser impact welding of aluminum to brass, J. Mater. Process. Technol., 2019, 269, p 190–199

N. Kahraman and B. Gülenç, Microstructural and mechanical properties of Cu-Ti plates bonded through explosive welding process, J. Mater. Process. Technol., 2005, 169(1), p 67–71

A. Nassiri and B. Kinsey, Numerical studies on high-velocity impact welding: smoothed particle hydrodynamics (SPH) and arbitrary Lagrangian–Eulerian (ALE), J. Manuf. Process., 2016, 24, p 376–381

M. Gloc, M. Wachowski, T. Plocinski, and K.J. Kurzydlowski, Microstructural and microanalysis investigations of bond titanium grade1/low alloy steel st52-3 N obtained by explosive welding, J. Alloys. Compd., 2016, 671, p 446–451

A. Nassiri, G. Chini, A. Vivek, G. Daehn, and B. Kinsey, Arbitrary Lagrangian–Eulerian finite element simulation and experimental investigation of wavy interfacial morphology during high velocity impact, Mater. Des., 2015, 88, p 345–358

S.A.A. Akbari-Mousavi, L.M. Barrett, and S.T.S. Al-Hassani, Explosive welding of metal plates, J. Mater. Process. Technol., 2008, 202, p 224–239

Acknowledgments

This work was supported by the National Natural Science Foundation of China (No. 51675241) and the college students’ practical innovation fund of Industry Center of Jiangsu University (No. ZXJG2018006).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, F., Wang, X., Wang, X. et al. Atomic Diffusion Behavior and Interface Waveform on the Laser Shock Welding of Aluminum to Nickel. J. of Materi Eng and Perform 29, 1336–1345 (2020). https://doi.org/10.1007/s11665-020-04671-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04671-7