Abstract

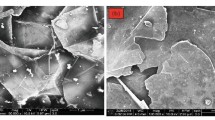

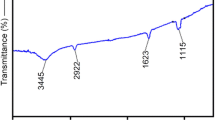

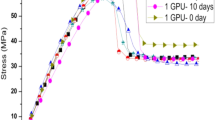

A special class of smart material was developed using shape memory polyurethane (SMPU) elastomer and graphene nanoplatelets (GNPs) via melt-blending process using micro-compounder. The shape recovery of the developed composites was studied under microwave irradiation. The nanocomposites were developed having 0.2, 0.4, 0.6, and 0.8 phr GNPs in the SMPU matrix. The effects of GNP reinforcement on morphology, shape memory effects, and viscoelastic properties of the composites were investigated. The recovery stress of virgin SMPU increased with reinforcement and maximized on the incorporation of 0.6 phr GNPs. The deformation-induced shape memory creation process influenced significantly the recovery stress of composites as compared to virgin SMPU. The recovery stresses of SMPU at 50, 75, and 100% strain were 1.5, 1.7, and 1.9 MPa, whereas the values of GNP-SMPU composites were 3.2, 3.4, and 4.1 MPa corresponding to 0.6 phr GNP reinforcement. The value of storage modulus above the glass transition temperature of SMPU increased from 9.2 to 15.1 MPa on the addition of 0.6 phr GNPs. The peak of the damping factor, tan δ shifted toward higher temperatures with the increased GNP content. The morphological study confirms the uniform dispersion of GNPs in the SMPU matrix. The microwave-induced heating of 0.8 phr GNP composite shows 80% shape recovery in 60 s, which is faster than convectional heating.

Similar content being viewed by others

References

S.A.R. Hashmi, H.C. Prasad, R. Abishera, H.N. Bhargaw, and A. Naik, Improved Recovery Stress in Multi-walled-Carbon-Nanotubes Reinforced Polyurethane, Mater. Des., 2015, 67, p 492. https://doi.org/10.1016/j.matdes.2014.10.062

W.M. Huang, Z. Ding, C.C. Wang, J. Wei, Y. Zhao, and H. Purnawali, Shape Memory Materials, Mater. Today, 2010, 13, p 54. https://doi.org/10.1016/S1369-7021(10)70128-0

Q. Meng and J. Hu, A Review of Shape Memory Polymer Composites and Blends, Compos. A Appl. Sci. Manuf., 2009, 40, p 1661–1672

Y. Wu, J. Hu, C. Zhang, J. Han, Y. Wang, and B. Kumar, A Facile Approach to Fabricate a UV/Heat Dual-Responsive Triple Shape Memory Polymer, J. Mater. Chem. A, 2015, 3, p 97. https://doi.org/10.1039/c4ta04881d

E. Pieczyska, M. Staszczak, M. Maj, H. Tobushi, S. Hayashi, Investigation of Thermal Effects Accompanying Tensile Deformation of Shape Memory Polymer PU-SMP, Meas. Autom. Monit., 2015, 61, p 203–205

T. Hisaaki, H. Hisashi, Y. Etsuko, and H. Shunichi, Thermomechanical Properties in a Thin Film of Shape Memory Polymer of Polyurethane Series, Smart Mater. Struct., 1996, 5, p 483

M. Zarek, M. Layani, I. Cooperstein, E. Sachyani, D. Cohn, and S. Magdassi, 3D Printing of Shape Memory Polymers for Flexible Electronic Devices, Adv. Mater., 2016, 28, p 4449. https://doi.org/10.1002/adma.201503132

W. Wang, D. Liu, Y. Liu, J. Leng, and D. Bhattacharyya, Electrical Actuation Properties of Reduced Graphene Oxide Paper/Epoxy-Based Shape Memory Composites, Compos. Sci. Technol., 2015, 106, p 20

X. Liu, H. Li, Q. Zeng et al., Electro-Active Shape Memory Composites Enhanced by Flexible Carbon Nanotube/Graphene Aerogels, J. Mater. Chem. A, 2015, 3, p 11641

T. Liu, R. Huang, X. Qi, P. Dong, and Q. Fu, Facile Preparation of Rapidly Electro-Active Shape Memory Thermoplastic Polyurethane/Polylactide Blends Via Phase Morphology Control and Incorporation of Conductive Fillers, Polymer, 2017, 114, p 28

F.-P. Du, E.-Z. Ye, and W. Yang et al., Electroactive Shape Memory Polymer Based on Optimized Multi-Walled Carbon Nanotubes/Polyvinyl Alcohol Nanocomposites, Compos. Part B Eng., 2015, 68, p 170

A.M. Schmidt, Electromagnetic Activation of Shape Memory Polymer Networks Containing Magnetic Nanoparticles, Macromol. Rapid Commun., 2006, 27, p 1168

R. Mohr, K. Kratz, T. Weigel, M. Lucka-Gabor, M. Moneke, and A. Lendlein, Initiation of Shape-Memory Effect by Inductive Heating of Magnetic Nanoparticles in Thermoplastic Polymers, Proc. Natl. Acad. Sci. USA, 2006, 103, p 3540

B. Yang, W. Huang, C. Li, and L. Li, Effects of Moisture on the Thermomechanical Properties of a Polyurethane Shape Memory Polymer, Polymer, 2006, 47, p 1348

S. Chen, J. Hu, C.-W. Yuen, and L. Chan, Novel Moisture-Sensitive Shape Memory Polyurethanes Containing Pyridine Moieties, Polymer, 2009, 50, p 4424

X.J. Han, Z.Q. Dong, M.M. Fan et al., pH-Induced Shape-Memory Polymers, Macromol. Rapid Commun., 2012, 33, p 1055

H. Chen, Y. Li, Y. Liu, T. Gong, L. Wang, and S. Zhou, Highly pH-Sensitive Polyurethane Exhibiting Shape Memory and Drug Release, Polym. Chem., 2014, 5, p 5168

C.D. Eisenbach, Isomerization of Aromatic Azo Chromophores in Poly (Ethyl Acrylate) Networks and Photomechanical Effect, Polymer, 1980, 21, p 1175

M.H. Li, P. Keller, B. Li, X. Wang, and M. Brunet, Light-Driven Side-On Nematic Elastomer Actuators, Adv. Mater., 2003, 15, p 569

H. Finkelmann, E. Nishikawa, G. Pereira, and M. Warner, A New Opto-Mechanical Effect in Solids, Phys. Rev. Lett., 2001, 87, p 015501

Y. Fang, Y. Ni, S.-Y. Leo, C. Taylor, V. Basile, and P. Jiang, Reconfigurable Photonic Crystals Enabled by Pressure-Responsive Shape-Memory Polymers, Nat. Commun., 2015, 6, p 7416

Y.-Y. Xiao, X.-L. Gong, Y. Kang, Z.-C. Jiang, S. Zhang, and B.-J. Li, Light-, pH-and Thermal-Responsive Hydrogels with the Triple-Shape Memory Effect, Chem. Commun., 2016, 52, p 10609

C. Liu, H. Qin, and P. Mather, Review of Progress in Shape-Memory Polymers, J. Mater. Chem., 2007, 17, p 1543

J. Hu, Y. Zhu, H. Huang, and J. Lu, Recent Advances in Shape-Memory Polymers: Structure, Mechanism, Functionality, Modeling and Applications. Prog. Polym. Sci., 2012, 37, p 1720

I.A. Rousseau, Challenges of Shape Memory Polymers: A Review of the Progress Toward Overcoming SMP’s Limitations, Polym. Eng. Sci., 2008, 48, p 2075

Y. Liu, K. Gall, M.L. Dunn, and P. McCluskey, Thermomechanics of Shape Memory Polymer Nanocomposites, Mech. Mater., 2004, 36, p 929

K. Gall, M.L. Dunn, Y. Liu, D. Finch, M. Lake, and N.A. Munshi, Shape Memory Polymer Nanocomposites, Acta Mater., 2002, 50, p 5115

F. Cao and S.C. Jana, Nanoclay-Tethered Shape Memory Polyurethane Nanocomposites, Polymer, 2007, 48, p 3790. https://doi.org/10.1016/j.polymer.2007.04.027

C.A. Garcia Rosales, M.F. Garcia Duarte, H. Kim et al., 3D Printing of Shape Memory Polymer (SMP)/Carbon Black (CB) Nanocomposites with Electro-Responsive Toughness Enhancement, Mater. Res. Exp., 2018, 5, p 065704. https://doi.org/10.1088/2053-1591/aacd53

A. Olalla, V. Sessini, E. Torres, and L. Peponi, Multifunctional Polymeric Nanocomposites Based on Cellulosic Reinforcements, Elsevier, Amsterdam, 2016

S.M. Oh, K.M. Oh, T.D. Dao, H.M. H-i Lee, and B.K.Kim Jeong, The Modification of Graphene with Alcohols and Its Use in Shape Memory Polyurethane Composites, Polymer, 2013, 62, p 54. https://doi.org/10.1002/pi.4366

L. Tan, L. Gan, J. Hu, Y. Zhu, and J. Han, Functional Shape Memory Composite Nanofibers with Graphene Oxide Filler, Compos. Part A: Appl. Sci. Manuf., 2015, 76, p 115. https://doi.org/10.1016/j.compositesa.2015.04.015

F. Memarian, A. Fereidoon, and M. Ghorbanzadeh Ahangari, The Shape Memory, and The Mechanical and Thermal Properties of TPU/ABS/CNT: A Ternary Polymer Composite, RSC Adv., 2016, 6, p 101038. https://doi.org/10.1039/c6ra23087c

D.I. Arun, K.S. Santhosh Kumar, B. Satheesh Kumar, P. Chakravarthy, M. Dona, and B. Santhosh, High Glass-Transition Polyurethane-Carbon Black Electro-Active Shape Memory Nanocomposite for Aerospace Systems, Mater. Sci. Technol., 2019, 35, p 596. https://doi.org/10.1080/02670836.2019.1575054

H. Lu, Y. Liu, and J. Leng, Carbon Nanopaper Enabled Shape Memory Polymer Composites for Electrical Actuation and Multifunctionalization, Macromol. Mater. Eng., 2012, 297, p 1138. https://doi.org/10.1002/mame.201200235

H. Lu, Y. Liu, J. Gou, L. Jinsong, and S. Du, Synergistic Effect of Carbon Nanofiber and Carbon Nanopaper on Shape Memory Polymer Composite, Appl. Phys. Lett., 2010, 96, p 084102. https://doi.org/10.1063/1.3323096

S.K. Yadav and J.W. Cho, Functionalized Graphene Nanoplatelets for Enhanced Mechanical and Thermal Properties of Polyurethane Nanocomposites, Appl. Surf. Sci., 2013, 266, p 360. https://doi.org/10.1016/j.apsusc.2012.12.028

Y.C. Jung, J.H. Kim, T. Hayashi et al., Fabrication of Transparent, Tough, Conductive Shape-Memory Polyurethane Films by Incorporating a Small Amount of High-Quality Graphene, Macromol. Rapid Commun., 2012, 33, p 628

H.J. Yoo, S.S. Mahapatra, and J.W. Cho, High-Speed Actuation and Mechanical Properties of Graphene-Incorporated Shape Memory Polyurethane Nanofibers, J. Phys. Chem. C, 2014, 118, p 10408. https://doi.org/10.1021/jp500709m

H. Du, Y. Yu, G. Jiang, J. Zhang, and J. Bao, Microwave-Induced Shape-Memory Effect of Chemically Crosslinked Moist Poly(vinyl alcohol) Networks, Macromol. Chem. Phys., 2011, 212, p 1460. https://doi.org/10.1002/macp.201100149

K. Yu, Y. Liu, and J. Leng, Shape Memory Polymer/CNT Composites and Their Microwave Induced Shape Memory Behaviors, RSC Adv., 2014, 4, p 2961. https://doi.org/10.1039/c3ra43258k

F. Zhang, T. Zhou, Y. Liu, and J. Leng, Microwave Synthesis and Actuation of Shape Memory Polycaprolactone Foams with High Speed, Sci. Rep., 2015, 5, p 11152. https://doi.org/10.1038/srep11152

Acknowledgments

One of the authors (RKG) is highly thankful to CSIR for granting fellowship under which the present work was carried out. The authors are also very thankful to Dr. A. K. Srivastava for his constant encouragement to publish research work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gupta, R.K., Hashmi, S.A.R., Verma, S. et al. Recovery Stress and Storage Modulus of Microwave-Induced Graphene-Reinforced Thermoresponsive Shape Memory Polyurethane Nanocomposites. J. of Materi Eng and Perform 29, 205–214 (2020). https://doi.org/10.1007/s11665-020-04568-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04568-5