Abstract

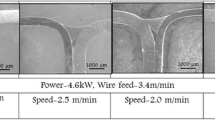

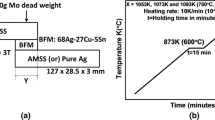

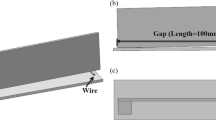

In the present study, a galvanized steel and a AA6082 aluminum alloy sheet of 2 mm thick were weld-brazed by applying laser and using 2-mm-diameter solid Al-12% Si filler wire at 2.5 m/min wire feed rate and 2 m/min laser scan speed at varying laser power (4.0, 3.5, 3.0 kW) in flange configuration. The microstructural investigation of the laser weld-brazed joints revealed the presence of two-layered intermetallic compound at steel/braze seam interface. The corresponding x-ray diffraction analysis of the steel/braze seam interface showed the presence of Al-Fe-Si-based ternary intermetallic phases. SEM and EDS analysis of the braze seam revealed the presence of α-Al grains surrounded by Mg2Si phase in the grain boundary region. Fine intermetallic layer was observed at lower heat-input condition. The corrosion performance of the brazed joints was studied with the help of immersion, salt spray, and electrochemical polarization tests in different electrolytes containing NaCl salt. Brazed joints experienced galvanic corrosion during immersed in corrosive media. From the salt spray test, it was revealed that galvanized steel was highly susceptible to corrosion compared to Al-rich phase. The polarization results showed a substantial change in corrosion resistance from steel interface to the brazed region due to the variation in microstructure. The samples brazed with low heat-input showed better corrosion resistance as compared to the joints made with high heat-input. Post-corrosion microstructure revealed intergranular corrosion at the brazed joint along with pit formation.

Similar content being viewed by others

References

K. Bouche, F. Barbier, and A. Coulet, Intermetallic Compound Layer Growth Between Solid Iron and Molten Aluminium, Mater. Sci. Eng. A, 1998, 249(1), p 67–175

L. Agudo, D. Eyidi, C.H. Schmaranzer, E. Arenholz, N. Jank, J. Bruckner, and A.R. Pyzalla, Intermetallic FexAly-Phases in a STEEL/AL-ALLOY FUSION WELD, J. Mater. Sci., 2007, 42(12), p 4205–4214

I. Bednarczyk, D. Kuc, and G. Niewielski, The Structure of FeAl And Fe3Al-5% Cr Intermetallic Phase-Based Alloys After Hot Deformation Processes, Arch. Mater. Sci. Eng., 2008, 30(1), p 5–8

S. Katayama, Laser Welding of Aluminium Alloys and Dissimilar Metals, Weld. Int., 2004, 18(8), p 618–625

L. Cui, B. Chen, L. Chen, and D. He, Dual Beam Laser Keyhole Welding of Steel/Aluminum Lapped Joints, J. Mater. Process. Technol., 2018, 256, p 87–97

S. Zuniga and S.D. Sheppard, Resistance Spot Weld Failure Loads and Modes in Overload Conditions, Fatigue Fract. Mech., 1997, 27, p 469–489

E. Taban, J.E. Gould, and J.C. Lippold, Dissimilar Friction Welding of 6061-T6 Aluminum and AISI, 1018 Steel: Properties and Microstructural Characterization, Mater. Des., 2010, 31(5), p 2305–2311

R. Roth, J. Clark, and A. Kelkar, Automobile Bodies: Can Aluminum be an Economical Alternative to Steel, JOM, 2001, 53(8), p 28–32

X. Sun, E.V. Stephens, M.A. Khaleel, H. Shao, and M. Kimchi, Resistance Spot Welding of Aluminum Alloy to Steel with Transition Material-from Process to Performance-Part I: Experimental Study, Weld. J., 2004, 83, p 188–195

A. Kouadri-David and P.S.M. Team, Study of Metallurgic and Mechanical Properties of Laser Welded Heterogeneous Joints Between DP600 Galvanised Steel and Aluminium 6082, Mater. Des., 2014, 54(1), p 184–195

J. Sun, Q. Yan, W. Gao, and J. Huang, Investigation of Laser Welding on Butt Joints of Al/Steel Dissimilar Materials, Mater. Des., 2015, 83(15), p 120–128

C. Dharmendra, K.P. Rao, J. Wilden, and S. Reich, Study on Laser Welding-Brazing of Zinc Coated Steel to Aluminum Alloy with a Zinc Based Filler, Mater. Sci. Eng. A, 2011, 528(3), p 1497–1503

J. Wloka, H. Laukant, U. Glatzel, and S. Virtanen, Corrosion Properties of Laser Beam Joints of Aluminium with zinc-Coated Steel, Corros. Sci., 2007, 49(11), p 4243–4258

L.H. Laukant, C. Wallmann, M. Müller, M. Korte, B. Stirn, H.G. Haldenwanger, and U. Glatzel, Fluxless Laser Beam Joining of Aluminium with Zinc Coated Steel, Sci. Technol. Weld. Join., 2005, 10(2), p 219–226

Y. Shi, J. Li, G. Zhang, J. Huang, and Y. Gu, Corrosion Behavior of Aluminum-Steel Weld-Brazing Joint, J. Mater. Eng. Perform., 2016, 25(5), p 1916–1923

M. Mohammadpour, N. Yazdian, H.P. Wang, B. Carlson, and R. Kovacevic, Effect of Filler Wire Composition on Performance of Al/Galvanized Steel Joints by twin Spot Laser Welding-Brazing Method, J. Mater. Process. Technol., 2018, 31(1), p 20–34

J.R. Davis, Corrosion of Aluminum and Aluminum Alloys, ASM International, Almere, 1999, p 173–220

A. Koltsov, N. Bailly, and L. Cretteur, Wetting and Laser Brazing of Zn-Coated Steel Products by Cu–Si Filler Metal, J. Mater. Sci., 2010, 45(8), p 2118–2125

M. Gatzen, T. Radel, C. Thomy, and F. Vollertsen, Wetting and Solidification Characteristics of Aluminium on Zinc Coated Steel in Laser Welding and Brazing, J. Mater. Process. Technol., 2016, 238, p 352–360

D. Narsimhachary, S. Pal, S.M. Shariff, G. Padmanabham, and A. Basu, AA6082 to DX56-Steel Laser Brazing: Process Parameter-Intermetallic Formation Correlation, J. Mater. Process. Technol., 2017, 26(9), p 4274–4281

S. Kou, Welding Metallurgy, 2nd ed., Wiley, London, 2003, p 155–157

S. Zhou, T. Zhang, Z. Xiong, X. Dai, C. Wu, and Z. Shao, Investigation of Cu–Fe-Based Coating Produced on Copper Alloy Substrate by Laser Induction Hybrid Rapid Cladding, Opt. Laser Technol., 2014, 59, p 131–136

W.R. Osório, N. Cheung, L.C. Peixoto, and A. Garcia, Corrosion Resistance and Mechanical Properties of an Al 9wt% Si Alloy Treated by Laser Surface Remelting, Int. J. Electrochem. Sci., 2009, 4(6), p 820–831

L. Liu and R. Xu, Investigation of Corrosion Behavior of Mg-Steel Laser-TIG Hybrid Lap Joints, Corros. Sci., 2012, 54, p 212–218

S. Basak, H. Das, T.K. Pal, and M. Shome, Corrosion Behavior of MIG Brazed and MIG Welded Joints of Automotive DP600-GI, Steel Sheet, J. Mater. Process. Technol., 2016, 25(12), p 5238–5251

F. Lu, B. Lu, X. Tang, and S. Yao, Study of Influencing Factors and Joint Performance of Laser Brazing on Zinc-Coated Steel Plate, Int. J. Adv. Manuf. Technol., 2008, 37(10), p 961–965

Y. Tao, T. Xiong, C. Sun, L. Kong, X. Cui, T. Li, and G.L. Song, Microstructure and Corrosion Performance of a Cold Sprayed Aluminium Coating on AZ91D Magnesium Alloy, Corros. Sci., 2010, 52(10), p 3191–3197

P.K. Rai, S. Shekhar, and K. Mondal, Development of Gradient Microstructure in Mild Steel and Grain Size Dependence of Its Electrochemical Response, Corros. Sci., 2018, 138, p 85–95

D.Q. Zhang, J. Li, H.G. Joo, and K.Y. Lee, Corrosion Properties of Nd: YAG Laser–GMA Hybrid Welded AA6061 Al Alloy and Its Microstructure, Corros. Sci., 2009, 51(6), p 1399–1404

R.G. Buchheit, Compilation of Corrosion Potentials Reported for Intermetallic Phases in Aluminum Alloys, J. Electroanal. Chem., 1995, 142(11), p 3994–3996

K.M. Fleming, A. Zhu, and J.R. Scully, Corrosion of AA6061 Brazed with an Al-Si Alloy: Effects of Si on Metallurgical and Corrosion Behaviour, Corrosion, 2012, 68(12), p 1126–1145

R. Ambat, A.J. Davenport, G.M. Scamans, and A. Afseth, Effect of Iron-Containing Intermetallic Particles on the Corrosion Behaviour of Aluminium, Corros. Sci., 2006, 48(11), p 3455–3471

C. Blanc, Y. Roques, and G. Mankowski, Application of Phase Shifting Interferometric Microscopy to Studies of the Behaviour of Coarse Intermetallic Particles in 6056 Aluminium Alloy, Corros. Sci., 1998, 40(6), p 1019–1035

Acknowledgments

XRD laboratory at Department of Metallurgical and Materials Engineering, NIT Rourkela supported by DST-FIST (Grant No: SR/FST/ETI-344-/2013 C and G) is greatly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Narsimhachary, D., Rai, P.K., Shariff, S.M. et al. Corrosion Behavior of Laser-Brazed Surface Made by Joining of AA6082 and Galvanized Steel. J. of Materi Eng and Perform 28, 2115–2127 (2019). https://doi.org/10.1007/s11665-019-03962-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-03962-y