Abstract

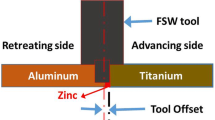

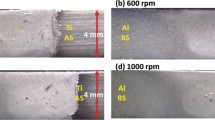

The welding of aluminum (Al) and titanium (Ti) is difficult and challenging due to the differences in their chemical and physical properties, and the formation of brittle intermetallic phases. In the present experiment, a zinc (Zn) interlayer was used during friction stir welding of Al to Ti. The weld was characterized in detail to understand the mechanisms associated with microstructural evolution and improvement in mechanical properties of the weld. X-ray computed tomography results reveal three-dimensional distribution of particles and flakes of titanium in the weld nugget. It was also observed that Ti particles are inhomogeneously distributed in the weld and the distribution depends on their morphology. Such a distribution of Ti was informative in understanding material flow. In addition, the consolidation of Zn in the Al matrix reveals the nature of material flow in the weld nugget as well. The importance of the Zn interlayer and mechanism of phase formation was explored in this study. It was characterized that the mechanical mixing of Zn with Al and Ti alters phase evolution and restricts the formation of conventional Al3Ti intermetallic phase. The presence of zinc homogenizes elemental distribution and inhibits the formation of brittle intermetallic phases, which leads to a substantial improvement in mechanical properties of the weld.

Similar content being viewed by others

References

T. Saeid, A. Abdollah-zadeh, and B. Sazgari, Weldability and Mechanical Properties of Dissimilar Aluminum–Copper Lap Joints Made by Friction Stir Welding, J. Alloys Compd., 2010, 490, p 652–655

Z. Liu, S. Ji, and X. Meng, Improving Joint Formation and Tensile Properties of Dissimilar Friction Stir Welding of Aluminum and Magnesium Alloys by Solving the Pin Adhesion Problem, J. Mater. Eng. Perform., 2018, 27, p 1404–1413

R. Borrisutthekul, Y. Miyashita, and Y. Mutoh, Dissimilar Material Laser Welding Between Magnesium Alloy AZ31B and Aluminum Alloy A5052-O, Sci. Technol. Adv. Mater., 2005, 6, p 199–204

H.-B. Chen, K. Yan, T. Lin, S.-B. Chen, C.-Y. Jiang, and Y. Zhao, The Investigation of Typical Welding Defects for 5456 Aluminum Alloy Friction Stir Welds, Mater. Sci. Eng. A, 2006, 433, p 64–69

P. Liu, Y. Li, H. Geng, and J. Wang, Microstructure Characteristics in TIG Welded Joint of Mg/Al Dissimilar Materials, Mater. Lett., 2007, 61, p 1288–1291

S.-Y. Kim, S.-B. Jung, C.-C. Shur, Y.-M. Yeon, and D.-U. Kim, Mechanical Properties of Copper to Titanium Joined by Friction Welding, J. Mater. Sci., 2003, 38, p 1281–1287

M.K.A. Fuji, T.H. North, K. Ameyama, and M. Aki, Mechanical Properties of Titanium-5083 Aluminum Alloy Friction Joints, Mater. Sci. Technol., 1997, 13, p 673–678

U. Dressler, G. Biallas, and U. Alfaro Mercado, Friction Stir Welding of Titanium Alloy TiAl6V4 to Aluminium Alloy AA2024-T3, Mater. Sci. Eng. A, 2009, 526, p 113–117

Y.C. Chen and K. Nakata, Microstructural Characterization and Mechanical Properties in Friction Stir Welding of Aluminum and Titanium Dissimilar Alloys, Mater. Des., 2009, 30, p 469–474

Q. Zheng, X. Feng, Y. Shen, G. Huang, and P. Zhao, Dissimilar Friction Stir Welding of 6061 Al to 316 Stainless Steel Using Zn as a Filler Metal, J. Alloys Compd., 2016, 686, p 693–701

A. Fuji, K. Ameyama, and T.H. North, Influence of Silicon in Aluminium on the Mechanical Properties of Titanium/Aluminium Friction Joints, J. Mater. Sci., 1995, 30, p 5185–5191

D. Yang, P. Hodgson, and C. Wen, The Kinetics of Two-Stage Formation of TiAl3 in Multilayered Ti/Al Foils Prepared by Accumulative Roll Bonding, Intermetallics, 2009, 17, p 727–732

I. Gunduz, T. Ando, E. Shattuck, P. Wong, and C. Doumanidis, Enhanced Diffusion and Phase Transformations During Ultrasonic Welding of Zinc and Aluminum, Scr. Mater., 2005, 52, p 939–943

V. Maier, H.W. Höppel, and M. Göken, Nanomechanical Behaviour of Al-Ti Layered Composites Produced by Accumulative Roll Bonding, J. Phys. Conf. Ser., 2010, 240, p 012108

G. Çam, G. İpekoğlu, and H. Tarık Serindağ, Effects of Use of Higher Strength Interlayer and External Cooling on Properties of Friction Stir Welded AA6061-T6 Joints, Sci. Technol. Weld. Join., 2014, 19, p 715–720

K.S. Anil Kumar, S.M. Murigendrappa, and H. Kumar, A Bottom-Up Optimization Approach for Friction Stir Welding Parameters of Dissimilar AA2024-T351 and AA7075-T651 Alloys, J. Mater. Eng. Perform., 2017, 26, p 3347–3367

N. Nadammal, S.V. Kailas, and S. Suwas, A Bottom-Up Approach for Optimization of Friction Stir Processing Parameters: A Study on Aluminium 2024-T3 alloy, Mater. Des., 2015, 65, p 127–138

A. Kar, S. Suwas, and S.V. Kailas, Two-Pass Friction Stir Welding of Aluminum Alloy to Titanium Alloy: A Simultaneous Improvement in Mechanical Properties, Mater. Sci. Eng. A, 2018, 733, p 199–210

K.-S. Bang, K.-J. Lee, H.-S. Bang, and H.-S. Bang, Interfacial Microstructure and Mechanical Properties of Dissimilar Friction Stir Welds between 6061-T6 Aluminum and Ti-6%Al-4%V Alloys, Mater. Trans., 2011, 52, p 974–978

H. Uzun, C. Dalle Donne, A. Argagnotto, T. Ghidini, and C. Gambaro, Friction Stir Welding of Dissimilar Al 6013-T4 To X5CrNi18-10 Stainless Steel, Mater. Des., 2005, 26, p 41–46

A. Wu, Z. Song, K. Nakata, J. Liao, and L. Zhou, Interface and Properties of the Friction Stir Welded Joints of Titanium Alloy Ti6Al4V with Aluminum Alloy 6061, Mater. Des., 2015, 71, p 85–92

G. Buffa, L. Donati, L. Fratini, and L. Tomesani, Solid State Bonding in Extrusion and FSW: Process Mechanics and Analogies, J. Mater. Process. Technol., 2006, 177, p 344–347

Z. Song, K. Nakata, A. Wu, J. Liao, and L. Zhou, Influence of Probe Offset Distance on Interfacial Microstructure and Mechanical Properties of Friction Stir Butt Welded Joint of Ti6Al4V and A6061 Dissimilar Alloys, Mater. Des., 2014, 57, p 269–278

P. Cavaliere, F. Panella, Effect of Tool Position on the Fatigue Properties of Dissimilar 2024-7075 Sheets Joined by Friction Stir Welding, J. Mater. Process. Technol., 2008, 206, p 249–255

K.S. Kumar, Positional Dependence of Material Flow in Friction Stir Welding: Analysis of Joint Line Remnant and Its Relevance to Dissimilar Metal Welding, Sci. Technol. Weld. Join., 2010, 15, p 305–311

M. Pourali, A. Abdollah-zadeh, T. Saeid, and F. Kargar, Influence of Welding Parameters on Intermetallic Compounds Formation in Dissimilar Steel/Aluminum Friction Stir Welds, J. Alloys Compd., 2017, 715, p 1–8

Q. Zhang, B.L. Xiao, and Z.Y. Ma, Mechanically Activated Effect of Friction Stir Processing in Al–Ti Reaction, Mater. Chem. Phys., 2013, 139, p 596–602

M. Sujata, S. Bhargava, and S. Sangal, On the Formation of TiAl3 During Reaction Between Solid Ti and Liquid Al, J. Mater. Sci. Lett., 1997, 16, p 1175–1178

M. Sujata, S. Bhargava, S. Suwas, and S. Sangal, On Kinetics of TiAl3 Formation During Reaction Synthesis from Solid Ti and Liquid Al, J. Mater. Sci. Lett., 2001, 20, p 2207–2209

K. Kumar and S.V. Kailas, On the Role of Axial Load and the Effect of Interface Position on the Tensile Strength of a Friction Stir Welded Aluminium Alloy, Mater. Des., 2008, 29, p 791–797

A. Abdollah-Zadeh, T. Saeid, and B. Sazgari, Microstructural and Mechanical Properties of Friction Stir Welded Aluminum/Copper Lap Joints, J. Alloys Compd., 2008, 460, p 535–538

T.U. Seidel and A.P. Reynolds, Two-Dimensional Friction Stir Welding Process Model Based on Fluid Mechanics, Sci. Technol. Weld. Join., 2003, 8, p 175–183

A. Fuji, In Situ Observation of Interlayer Growth During Heat Treatment of Friction Weld Joint Between Pure Titanium and Pure Aluminium, Sci. Technol. Weld. Join., 2002, 7, p 413–416

Y. Wei, J. Li, J. Xiong, F. Huang, F. Zhang, and S.H. Raza, Joining Aluminum to Titanium Alloy by Friction Stir Lap Welding with Cutting Pin, Mater. Charact., 2012, 71, p 1–5

M. Kreimeyer, F. Wagner, and F. Vollertsen, Laser Processing of Aluminum–Titanium-Tailored Blanks, Opt. Lasers Eng., 2005, 43, p 1021–1035

J.L. Murray, The Ti-Zn (Titanium–Zinc) System, Bull. Alloy Phase Diagr., 1984, 5, p 52–56

W.-S. Lee and C.-F. Lin, Plastic Deformation and Fracture Behaviour of Ti-6Al-4V Alloy Loaded with High Strain Rate Under Various Temperatures, Mater. Sci. Eng. A, 1998, 241, p 48–59

A. Kar, S. Suwas, and S.V. Kailas, An Investigation on Friction Stir Welding of Aluminum to Titanium Using a Nickel Interlayer, Indian Institute of Welding-International Congress, 2017

E. Sharghi and A. Farzadi, Simulation of Strain Rate, Material Flow, and Nugget Shape During Dissimilar Friction Stir Welding of AA6061 Aluminum Alloy and Al-Mg2Si Composite, J. Alloys Compd., 2018, 748, p 953–960

X. Sauvage, G. Wilde, S.V. Divinski, Z. Horita, and R.Z. Valiev, Grain Boundaries in Ultrafine Grained Materials Processed by Severe Plastic Deformation and Related Phenomena, Mater. Sci. Eng. A, 2012, 540, p 1–12

V.I. Nizhenko, Free Surface Energy as a Criterion for the Sequence of Intermetallic Layer Formation in Reaction Couples, Powder Metall. Met. Ceram., 2004, 43, p 273–279

Acknowledgments

Authors would like to thank the Defense Research and Development Organization (DRDO), Department of Science and Technology (DST), Ministry of Human Resources Development (MHRD), India, for support and research funding. We would also like to thank Institute X-ray Facility and Advanced Facility for Microscopy and Microanalysis (AFMM) at Indian Institute of Science (IISc), Bangalore, for providing the facilities.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kar, A., Kailas, S.V. & Suwas, S. Effect of Zinc Interlayer in Microstructure Evolution and Mechanical Properties in Dissimilar Friction Stir Welding of Aluminum to Titanium. J. of Materi Eng and Perform 27, 6016–6026 (2018). https://doi.org/10.1007/s11665-018-3697-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3697-8