Abstract

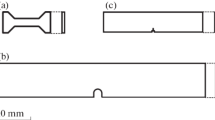

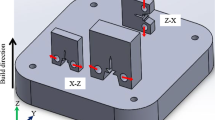

The fracture behavior of commercially pure titanium (CP-Ti) processed by accumulative roll bonding (ARB) was investigated in this study. Monolithic and Ti-SiC composite samples were first produced by ARB process and then subjected to uniaxial tensile testing at room temperature. Two different ductile fracture mechanisms including shear dimple rupture and equiaxed dimple rupture were observed in the initial and final ARB cycles, respectively. The difference in the rupture mechanism was attributed to different stress states at the crack tip and different densities of metallurgical defects. A non-uniform distribution of dimple size was obtained for fracture surfaces of the samples processed by a low number of ARB cycles. This was attributed to the heterogeneity of microstructure in the primary ARB cycles. The fracture surface of the samples processed by high ARB cycles represented more uniform dimples. This was attributed to more homogenous microstructure in the final cycles. Moreover, SiC particles showed a major role in fracture of samples, so that they affected the size and depth of the dimples, as well as the number of ARB cycles in which the transmission of the fracture mechanism occurred.

Similar content being viewed by others

References

Y. Saito, H. Utsunomiya, N. Tsuji, and T. Sakai, Novel Ultra-High Straining Process for Bulk Materials-Development of the Accumulative Roll-Bonding (ARB) Process, Acta Mater., 1999, 47(2), p 579–583

R. Jamaati and M.R. Toroghinejad, Application of ARB Process for Manufacturing High-Strength, Finely Dispersed and highly Uniform Cu/Al2O3 Composite, Mater. Sci. Eng. A, 2010, 527(27), p 7430–7435

M.R. Toroghinejad, R. Jamaati, A. Nooryan, and H. Edris, Hybrid Composites Produced by Anodizing and Accumulative Roll Bonding (ARB) Processes, Ceram. Int., 2014, 40(7), p 10027–10035

P.D. Motevalli and B. Eghbali, Microstructure and Mechanical Properties of Tri-metal Al/Ti/Mg Laminated Composite Processed by Accumulative roll Bonding, Mater. Sci. Eng. A, 2015, 628, p 135–142

V. Yousefi Mehr, A. Rezaeian, and M.R. Toroghinejad, Application of Accumulative Roll Bonding and Anodizing Process to Produce Al-Cu-Al2O3 composite, Mater. Des., 2015, 70, p 53–59

A. Das and S. Tarafder, Geometry of Dimples and its Correlation with Mechanical Properties in Austenitic Stainless Steel, Scr. Mater., 2008, 59(9), p 1014–1017

G.E. Dieter and D. Bacon, Mechanical Metallurgy, McGraw-Hill, New York, 1986

H.M. Tawancy, A. Ul-Hamid, and N.M. Abbas, Practical Engineering Failure Analysis, CRC Press, Boca Raton, 2004

J.P. Bandstra, D.A. Koss, A. Geltmacher, P. Matic, and R.K. Everett, Modeling Void Coalescence During Ductile Fracture of a Steel, Mater. Sci. Eng. A, 2004, 366(2), p 269–281

T.F. Morgeneyer and J. Besson, Flat to Slant Ductile Fracture Transition: Tomography Examination and Simulations Using Shear-Controlled Void Nucleation, Scr. Mater., 2011, 65(11), p 1002–1005

I. Barsoum and J. Faleskog, Rupture Mechanisms in Combined Tension and Shear-Micromechanics, Int. J. Solids Struct., 2007, 44(17), p 5481–5498

S. Roy, B.R. Nataraj, S. Suwas, S. Kumar, and K. Chattopadhyay, Accumulative Roll Bonding of Aluminum Alloys 2219/5086 Laminates: Microstructural Evolution and Tensile Properties, Mater. Des., 2012, 36, p 529–539

L. Su, C. Lu, H. Li, G. Deng, and K. Tieu, Investigation of Ultrafine Grained AA1050 Fabricated by Accumulative Roll Bonding, Mater. Sci. Eng. A, 2014, 614, p 148–155

C.Y. Liu, Q. Wang, Y.Z. Jia, B. Zhang, R. Jing, M.Z. Ma, Q. Jing, and R.P. Liu, Evaluation of Mechanical Properties of 1060-Al Reinforced with WC Particles Via Warm Accumulative Roll Bonding Process, Mater. Des., 2013, 43, p 367–372

R.N. Dehsorkhi, F. Qods, and M. Tajally, Investigation on Microstructure and Mechanical Properties of Al-Zn Composite During Accumulative Roll Bonding (ARB) Process, Mater. Sci. Eng. A, 2011, 530, p 63–72

M.R. Toroghinejad, F. Ashrafizadeh, and R. Jamaati, On the Use of Accumulative Roll Bonding Process to Develop Nanostructured Aluminum Alloy 5083, Mater. Sci. Eng. A, 2013, 561, p 145–151

A. Shabani, M.R. Toroghinejad, and A. Shafyei, Fabrication of Al/Ni/Cu Composite by Accumulative Roll Bonding and Electroplating Processes and Investigation of its Microstructure and Mechanical Properties, Mater. Sci. Eng. A, 2012, 558, p 386–393

M. Rezayat, A. Akbarzadeh, and A. Owhadi, Production of High Strength Al-Al2O3 Composite by Accumulative Roll Bonding, Compos. Part A, Appl. Sci. Manuf., 2012, 43(2), p 261–267

M. Karimi and M.R. Toroghinejad, An Alternative Method for Manufacturing High-Strength CP Ti-SiC Composites by Accumulative Roll Bonding Process, Mater. Des., 2014, 59, p 494–501

D. Terada, M. Inoue, H. Kitahara, and N. Tsuji, Change in Mechanical Properties and Microstructure of ARB Processed Ti during Annealing, Mater. Trans., 2008, 49, p 41–46

M. Karimi, M.R. Toroghinejad, and Kh Farmanesh, Multi-Response Optimization on the Annealing of Accumulative Roll Bonded Monolithic Ti and Ti-SiCp Composites, Mater. Des., 2015, 65, p 34–41

J.L. Milner, F. Abu-Farh, C. Bunget, Th Kurfess, and V.H. Hammond, Grain Refinement and Mechanical Properties of CP-Ti Processed by Warm Accumulative Roll Bonding, Mater. Sci. Eng. A, 2013, 561, p 109–117

J.A. Fellows, Metals Handbook: Fractography and Atlas of Fractographs, American Society for Metals, Cleveland, 1974

I. Barsoum, The Effect of Stress State in Ductile Failure, Diss, KTH, 2008

R.W. Hertzberg, R.P. Vinci, and J.L. Hertzberg, Deformation and Fracture Mechanics of Engineering Materials, Wiley, New York, 1996

R.G. Broadwell, Toughness and Fracture Behavior of Titanium, ASTM International, 1978

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Karimi, M., Toroghinejad, M.R. & Dutkiewicz, J. Fracture Analysis of ARB-Processed CP-Ti Sheets Under Unidirectional Tensile Loading. J. of Materi Eng and Perform 27, 6097–6106 (2018). https://doi.org/10.1007/s11665-018-3680-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3680-4