Abstract

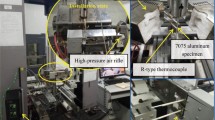

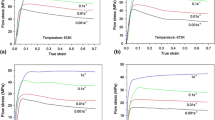

To improve the mechanical properties of aluminum alloy forgings, solution treatment and quenching is necessary. However, it becomes difficult to control the residual stress and deformation after solution treatment and quenching which always results in obtaining a part with an undesirable size, especially for a long stringer forging with an existing rib. Therefore, this paper demonstrates a quenching experiment and residual stress measurements for a ribbed aluminum alloy forging; the calculated results are close to the actual convective heat transfer coefficients. In addition, the heat transfer coefficient is introduced into the quenching simulation of a long stringer forging consisting of rib-web forging and plate forging. The influence of ribs on the residual stress and deformation of the forging is compared and analyzed. The results show that the heat transfer coefficient on the web without a rib is highest and the heat transfer coefficient on the web below the rib is lowest. Compared with the plate forging, the deformation direction of the rib-web forging is opposite, and the deformation of the rib-web forging is obviously increased.

Similar content being viewed by others

References

A.S. Warren, Developments and Challenges for Aluminum—A Boeing Perspective, in Materials Forum, Brisbane, Australia (2004), p. 24–31

T. Dursun and C. Soutis, Recent Developments in Advanced Aircraft Aluminium Alloys, Mater. Des., 2014, 56, p 862–871

Y.L. Deng, L. Wan, Y.Y. Zhang, and X.M. Zhang, Influence of Mg Content on Quench Sensitivity of Al-Zn-Mg-Cu Aluminum Alloys, J. Alloys Compd., 2011, 509, p 4636–4642

A. Deschamps and Y. Brechet, Nature and Distribution of Quench-Induced Precipitation in an Al-Zn-Mg-Cu Alloy, Scr. Mater., 1998, 39, p 1517–1522

N. Chobaut, P. Saelzle, G. Michel, D. Carron, and J.M. Drezet, Quench-Induced Stresses in AA2618 Forgings for Impellers: A Multiphysics and Multiscale Problem, JOM, 2015, 67, p 984–990

D.A. Tanner and J.S. Robinson, Residual Stress Magnitudes and Related Properties in Quenched Aluminium Alloys, Mater. Sci. Technol., 2006, 22, p 77–85

N. Mascarenhas and I. Mudawar, Analytical and Computational Methodology for Modeling Spray Quenching of Solid Alloy Cylinders, Int. J. Heat Mass Transf., 2010, 53, p 5871–5883

S. Denis, P. Archambault, E. Gautier, A. Simon, and G. Beck, Prediction of Residual Stress and Distortion of Ferrous and Non-ferrous Metals: Current Status and Future Developments, J. Mater. Eng. Perform., 2002, 11, p 92–102

J. Zhang, Y.L. Deng, W. Yang, S.S. Hu, and X.M. Zhang, Design of the Multi-Stage Quenching Process for 7050 Aluminum Alloy, Mater. Des., 2014, 56, p 334–344

J.S. Robinson and D.A. Tanner, Reducing Residual Stress in 7050 Aluminum Alloy Die Forgings by Heat Treatment, J. Eng. Mater. Technol. Trans. ASME, 2008, 130, p 1–8

P. Hofer, E. Kaschnitz, and P. Schumacher, Distortion and Residual Stress in High-Pressure Die Castings: Simulation and Measurements, JOM, 2014, 66, p 1638–1646

O. Kessler and M. Reich, Similarities and Differences in Heat Treatment Simulation of Aluminium Alloys and Steels, Materialwissensch. Werkst., 2009, 40, p 473–478

K. Babu and T.S.P. Kumar, Mathematical Modeling of Surface Heat Flux During Quenching, Metall. Mater. Trans. B, 2010, 41, p 214–224

X.W. Yang, J.C. Zhu, Z.S. Nong, Z.H. Lai, and D. He, FEM Simulation of Quenching Process in A357 Aluminum Alloy Cylindrical Bars and Reduction of Quench Residual Stress Through Cold Stretching Process, Comput. Mater. Sci., 2013, 69, p 396–413

R. Kopun, L. Skerget, M. Hribersek, D.S. Zhang, B. Stauder, and D. Greif, Numerical Simulation of Immersion Quenching Process for Cast Aluminium Part at Different Pool Temperatures, Appl. Therm. Eng., 2014, 65, p 74–84

Y.B. Dong, W.Z. Shao, J.T. Jiang, D.Y. Chao, and L. Zhen, Influence of Quenching Rate on Microstructure and Dimensional Stability of Al-Cu-Mg-Si Alloy, Mater. Sci. Technol., 2016, 32, p 1861–1868

B.W. Xiao, Q.G. Wang, P. Jadhav, and K.Y. Li, An Experimental Study of Heat Transfer in Aluminum Castings During Water Quenching, J. Mater. Process. Tech., 2010, 210, p 2023–2028

L. Zhang, X. Feng, Z.G. Li, and C.Y. Liu, FEM Simulation and Experimental Study on the Quenching Residual Stress of Aluminum Alloy 2024, Proc. Inst. Mech. Eng. B J. Eng., 2013, 227, p 954–964

M. Koc, J. Culp, and T. Altan, Prediction of Residual Stresses in Quenched Aluminum Blocks and their Reduction through Cold Working Processes, J. Mater. Process. Technol., 2006, 174, p 342–354

B.H. Nie, P.Y. Liu, and T.T. Zhou, Effect of Compositions on the Quenching Sensitivity of 7050 and 7085 Alloys, Mater. Sci. Eng. A, 2016, 667, p 106–114

D.Q. Shi, K.J. Kang, G.L. Gao, and Z.J. Chen, Effect of Quench Process on Mechanical Properties and Conductivity of 7475 Alloy, Mater. Trans., 2016, 57, p 37–41

C.B. Li, S.L. Wang, D.Z. Zhang, S.D. Liu, Z.J. Shan, and X.M. Zhang, Effect of Zener–Hollomon Parameter on Quench Sensitivity of 7085 Aluminum Alloy, J. Alloys Compd., 2016, 688, p 456–462

M.J. Wang, G. Yang, C.Q. Huang, and B. Chen, Simulation of Temperature and Stress in 6061 Aluminum Alloy During Online Quenching Process, Trans. Nonferrous Met. Soc., 2014, 24, p 2168–2173

N. Jarvstrat and S. Tjotta, Process Model for On-Line Quenching of Aluminium Extrusions, Metall. Mater. Trans. B, 1996, 27, p 501–508

D.H. Ko, D.C. Ko, H.J. Lim, J.M. Lee, and B.M. Kim, Prediction and Measurement of Relieved Residual Stress by the Cryogenic Heat Treatment for Al6061 Alloy: Mechanical Properties and Microstructure, J. Mech. Sci. Technol., 2013, 27, p 1949–1955

H. Gong, Y.X. Wu, and K. Liao, Prediction Model of Residual Stress Field in Aluminum Alloy Plate, J. Cent. South Univ. Technol., 2011, 18, p 285–289

B.W. Xiao, K.Y. Li, Q.G. Wang, and Y.M. Rong, Numerical Simulation and Experimental Validation of Residual Stresses in Water-Quenched Aluminum Alloy Castings, J. Mater. Eng. Perform., 2011, 20, p 1648–1657

N. Xu, Q.N. Song, Y.F. Bao, Y.F. Jiang, and J. Shen, Achieving an Excellent Strength-Ductility Synergy in Zircaloy-4 by FSW with Rapid Cooling, Mater. Sci. Technol., 2018, 34, p 20–28

S. Bikass, B. Andersson, A. Pilipenko, and H.P. Langtangen, Spray Footprint Effect on the Induced Distortion by the Cooling Process in the Aluminum Extrusion Process, Appl. Therm. Eng., 2013, 57, p 14–23

D.A. Lados, D. Apelian, and L.B. Wang, Minimization of Residual Stress in Heat-Treated Al-Si-Mg Cast Alloys Using Uphill Quenching: Mechanisms and Effects on Static and Dynamic Properties, Mater. Sci. Eng. A, 2010, 527, p 3159–3165

J.D. Cui, Y.P. Yi, and G.Y. Luo, Numerical and Experimental Research on Cold Compression Deformation Method for Reducing Quenching Residual Stress of 7A85 Aluminum Alloy Thick Block Forging, Adv. Mater. Sci. Eng., 2017, 2017, p 1–6

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, X., Wang, D., Liang, N. et al. Influences of Ribs on the Residual Stress and Deformation of Long Stringer Aluminum Alloy Forgings During Quenching. J. of Materi Eng and Perform 27, 5350–5359 (2018). https://doi.org/10.1007/s11665-018-3600-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-018-3600-7