Abstract

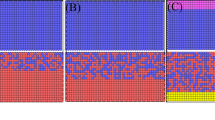

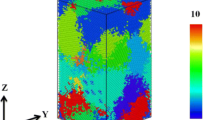

In this paper, molecular dynamics (MD) simulation deformation studies on the Al (metal)–Cu50Zr50 (metallic glass) model interface is carried out based on cohesive zone model. The interface is subjected to mode-I loading at a strain rate of 109 s−1 and temperature of 100 K. The dislocations reactions and evolution of dislocation densities during the deformation have been investigated. Atomic interactions between Al, Cu and Zr atoms are modeled using EAM (embedded atom method) potential, and a timestep of 0.002 ps is used for performing the MD simulations. A circular crack and rectangular notch are introduced at the interface to investigate the effect on the deformation behavior and fracture. Further, scale size effect is also investigated. The structural changes and evolution of dislocation density are also examined. It is found that the dominant deformation mechanism is by Shockley partial dislocation nucleation. Amorphization is observed in the Al regions close to the interface and occurs at a lower strain in the presence of a crack. The total dislocation density is found to be maximum after the first yield in both the perfect and defect interface models and is highest in the case of perfect interface with a density of 6.31 × 1017 m−2. In the perfect and circular crack defect interface models, it is observed that the fraction of Shockley partial dislocation density decreases, whereas that of strain rod dislocations increases with increase in strain.

Similar content being viewed by others

References

M. Lee, Fabrication of Ni–Nb–Ta Metallic Glass Reinforced Al-Based Alloy Matrix Composites by Infiltration Casting Process, Scr. Mater., 2004, 50, p 1367–1371. doi:10.1016/j.scriptamat.2004.02.038

S. Scudino, G. Liu, K.G.G. Prashanth, B. Bartusch, K.B. Surreddi, B.S. Murty et al., Mechanical Properties of Al-Based Metal Matrix Composites Reinforced with Zr-Based Glassy Particles Produced by Powder Metallurgy, Acta Mater., 2009, 57, p 2029–2039. doi:10.1016/j.actamat.2009.01.010

S. Scudino, K.B. Surreddi, S. Sager, M. Sakaliyska, J.S. Kim, W. Löser et al., Production and Mechanical Properties of Metallic Glass-Reinforced Al-Based Metal Matrix Composites, J. Mater. Sci., 2008, 43, p 4518–4526. doi:10.1007/s10853-008-2647-5

R. Zheng, H. Yang, T. Liu, K. Ameyama, and C. Ma, Microstructure and Mechanical Properties of Aluminum Alloy Matrix Composites Reinforced with Fe-Based Metallic Glass Particles, Mater. Des., 2014, 53, p 512–518. doi:10.1016/j.matdes.2013.07.048

D.V. Dudina, K. Georgarakis, M. Aljerf, Y. Li, M. Braccini, A.R. Yavari et al., Cu-Based Metallic Glass Particle Additions to Significantly Improve Overall Compressive Properties of an Al Alloy, Compos. Part A Appl. Sci. Manuf., 2010, 41, p 1551–1557. doi:10.1016/j.compositesa.2010.07.004

S. Ozden, R. Ekici, and F. Nair, Investigation of Impact Behaviour of Aluminium Based SiC Particle Reinforced Metal-Matrix Composites, Compos. Part A Appl. Sci. Manuf., 2007, 38, p 484–494. doi:10.1016/j.compositesa.2006.02.026

W.J. Kim and S.H. Lee, High-Temperature Deformation Behavior of Carbon Nanotube (CNT)-Reinforced Aluminum Composites and Prediction of Their High-Temperature Strength, Compos. Part A Appl. Sci. Manuf., 2014, 67, p 308–315. doi:10.1016/j.compositesa.2014.09.008

S. Li, Y. Su, X. Zhu, H. Jin, Q. Ouyang, and D. Zhang, Enhanced Mechanical Behavior and Fabrication of Silicon Carbide Particles Covered by In-situ Carbon Nanotube Reinforced 6061 Aluminum Matrix Composites, Mater. Des., 2016, 107, p 130–138. doi:10.1016/j.matdes.2016.06.021

Z. Xiong, L. Geng, and C.K. Yao, Investigation of High-Temperature Deformation Behavior of a SiC Whisker Reinforced 6061 Aluminium Composite, Compos. Sci. Technol., 1990, 39, p 117–125. doi:10.1016/0266-3538(90)90050-F

H.S. Kim, On the Rule of Mixtures for the Hardness of Particle Reinforced Composites, Mater. Sci. Eng., A, 2000, 289, p 30–33. doi:10.1016/S0921-5093(00)00909-6

R. Schaller, Metal Matrix Composites, a Smart Choice for High Damping Materials, J. Alloys Compd., 2003, 355, p 131–135. doi:10.1016/S0925-8388(03)00239-1

C.R. Dandekar and Y.C. Shin, Effect of Porosity on the Interface Behavior of an Al2O3–Aluminum Composite: A Molecular Dynamics Study, Compos. Sci. Technol., 2011, 71, p 350–356

C.R. Dandekar and Y.C. Shin, Molecular Dynamics Based Cohesive Zone Law for Describing Al-SiC Interface Mechanics, Compos. Part A Appl. Sci. Manuf., 2011, 42, p 355–363. doi:10.1016/j.compositesa.2010.12.005

A. Needleman, A Continuum Model for Void Nucleation by Inclusion Debonding, J. Appl. Mech., 1987, 54, p 525. doi:10.1115/1.3173064

D.S. Dugdale, Yielding of Steel Sheets Containing Slits, J. Mech. Phys. Solids, 1960, 8, p 100–104

G.I. Barenblatt, The Mathematical Theory of Equilibrium Cracks in Brittle Fracture, Adv. Appl. Mech., 1962, 7, p 55–129

Z.H. Jin and C.T. Sun, Cohesive Zone Modeling of Interface Fracture in Elastic Bi-materials, Eng. Fract. Mech., 2005, 72, p 1805–1817. doi:10.1016/j.engfracmech.2004.09.011

C.T. Sun and Z.H. Jin, Modeling of Composite Fracture Using Cohesive Zone and Bridging Models, Compos. Sci. Technol., 2006, 66, p 1297–1302. doi:10.1016/j.compscitech.2005.10.013

D.E. Spearot, K.I. Jacob, and D.L. McDowell, Non-local Separation Constitutive Laws for Interfaces and Their Relation to Nanoscale Simulations, Mech. Mater., 2004, 36, p 825–847. doi:10.1016/j.mechmat.2003.08.002

W.-P. Wu, N.-L. Li, and Y.-L. Li, Molecular Dynamics-Based Cohesive Zone Representation of Microstructure and Stress Evolutions of Nickel Intergranular Fracture Process: Effects of Temperature, Comput. Mater. Sci., 2016, 113, p 203–210. doi:10.1016/j.commatsci.2015.12.001

A.P. Awasthi, D.C. Lagoudas, and D.C. Hammerand, Modeling of Graphene–Polymer Interfacial Mechanical Behavior Using Molecular Dynamics, Model. Simul. Mater. Sci. Eng., 2009, 17, p 15002. doi:10.1088/0965-0393/17/1/015002

P. Gupta, S. Pal, and N. Yedla, Molecular Dynamics Based Cohesive Zone Modeling of Al (Metal)–Cu50Zr50 (Metallic Glass) Interfacial Mechanical Behavior and Investigation of Dissipative Mechanisms, Mater. Des., 2016, 105, p 41–50

S. Plimpton, Fast Parallel Algorithms for Short-Range Molecular Dynamics. J. Comput. Phys. 117, 1–19 (1995). file:///D:/ash/aswin-new/files/715/Plimpton - 1995 - Fast Parallel Algorithms for Short-Range Molecular.pdf

S. Plimpton, LAMMPS: Molecular Dynamics Simulator (2011), http://Lammps.sandia.gov/

R. Komanduri, N. Chandrasekaran, and L.M. Raff, Molecular Dynamics (MD) Simulation of Uniaxial Tension of Some Single-Crystal Cubic Metals at Nanolevel, Int. J. Mech. Sci., 2001, 43, p 2237–2260. doi:10.1016/S0020-7403(01)00043-1

Z.S. Pereira and E.Z. Da Silva, Cold Welding of Gold and Silver Nanowires: A Molecular Dynamics Study, J. Phys. Chem. C, 2011, 115, p 22870–22876

X.W. Zhou, R.A. Johnson, and H.N.G. Wadley, Misfit-Energy-Increasing Dislocations in Vapor-Deposited CoFe/NiFe Multilayers, Phys. Rev. B, 2004, 69, p 144113

L. Yang, G.-Q. Guo, L.-Y. Chen, S.-H. Wei, J.-Z. Jiang, and X.-D. Wang, Atomic Structure in Al-Doped Multicomponent Bulk Metallic Glass, Scr. Mater., 2010, 63, p 879–882

K. Gall, M.F. Horstemeyer, M. Van Schilfgaarde, and M.I. Baskes, Atomistic Simulations on the Tensile Debonding of an Aluminum-Silicon Interface, J. Mech. Phys. Solids, 2000, 48, p 2183–2212. doi:10.1016/S0022-5096(99)00086-1

S. Nosé, A Molecular Dynamics Method for Simulations in the Canonical Ensemble, Mol. Phys., 1984, 52, p 255–268

W.G. Hoover, Canonical Dynamics: Equilibrium Phase-Space Distributions, Phys. Rev. A, 1985, 31, p 1695

V.K. Sutrakar and D.R. Mahapatra, Effects of Isothermal and Adiabatic Thermal Loadings on Size and Strain Rate Dependence of Copper Nanowire, Def. Sci. J., 2009, 59, p 252

J. Diao, K. Gall, M.L. Dunn, and J.A. Zimmerman, Atomistic Simulations of the Yielding of Gold Nanowires, Acta Mater., 2006, 54, p 643–653

C.L. Kelchner, S.J. Plimpton, and J.C. Hamilton, Dislocation Nucleation and Defect Structure During Surface Indentation, Phys. Rev. B Condens. Matter Mater. Phys., 1998, 58, p 11085–11088. doi:10.1103/PhysRevB.58.11085

A. Stukowski, Visualization and Analysis of Atomistic Simulation Data with OVITO–the Open Visualization Tool, Model. Simul. Mater. Sci. Eng., 2010, 18, p 15012. doi:10.1088/0965-0393/18/1/015012

A. Stukowski, V.V. Bulatov, and A. Arsenlis, Automated Identification and Indexing of Dislocations in Crystal Interfaces, Model. Simul. Mater. Sci. Eng., 2012, 20, p 85007

L. Yuan, D. Shan, and B. Guo, Molecular Dynamics Simulation of Tensile Deformation of Nano-Single Crystal Aluminum, J. Mater. Process. Technol., 2007, 184, p 1–5. doi:10.1016/j.jmatprotec.2006.10.042

S.J.A. Koh, H.P. Lee, C. Lu, and Q.H. Cheng, Molecular Dynamics Simulation of a Solid Platinum Nanowire Under Uniaxial Tensile Strain: Temperature and Strain-Rate Effects, Phys. Rev. B, 2005, 72, p 85414

P. Wang, W. Chou, A. Nie, Y. Huang, H. Yao, and H. Wang, Molecular Dynamics Simulation on Deformation Mechanisms in Body-Centered-Cubic Molybdenum Nanowires, J. Appl. Phys., 2011, 110, p 93521. doi:10.1063/1.3660251

P. Yu, K.B. Kim, J. Das, F. Baier, W. Xu, and J. Eckert, Fabrication and Mechanical Properties of Ni–Nb Metallic Glass Particle-Reinforced Al-Based Metal Matrix Composite, Scr. Mater., 2006, 54, p 1445–1450. doi:10.1016/j.scriptamat.2006.01.001

A.P. Divecha, S.G. Fishman, and S.D. Karmarkar, Silicon Carbide Reinforced Aluminum—A Formable Composite, JOM, 1981, 33, p 12–17

Y. Zhou, W. Yang, M. Hu, and Z. Yang, The Typical Manners of Dynamic Crack Propagation Along the Metal/Ceramics Interfaces: A Molecular Dynamics Study, Comput. Mater. Sci., 2016, 112, p 27–33

K.J. Zhao, C.Q. Chen, Y.P. Shen, and T.J. Lu, Molecular Dynamics Study on the Nano-Void Growth in Face-Centered Cubic Single Crystal Copper, Comput. Mater. Sci., 2009, 46, p 749–754

G.E. Dieter and D.J. Bacon, Mechanical Metallurgy, Vol. 3, McGraw-hill, New York, 1986

V. Yamakov, D. Wolf, S.R. Phillpot, A.K. Mukherjee, and H. Gleiter, Dislocation Processes in the Deformation of Nanocrystalline Aluminium by Molecular-Dynamics Simulation, Nat. Mater., 2002, 1, p 45–48. doi:10.1038/nmat700

G. Sainath and B.K. Choudhary, Molecular Dynamics Simulation of Twin Boundary Effect on Deformation of Cu Nanopillars, Phys. Lett. A, 2015, 379, p 1902–1905. doi:10.1016/j.physleta.2015.05.027

V. Yamakov, D. Wolf, S.R. Phillpot, and H. Gleiter, Dislocation–Dislocation and Dislocation–Twin Reactions In Nanocrystalline Al by Molecular Dynamics Simulation, Acta Mater., 2003, 51, p 4135–4147. doi:10.1016/S1359-6454(03)00232-5

M. Chen, E. Ma, K.J. Hemker, H. Sheng, Y. Wang, and X. Cheng, Deformation Twinning in Nanocrystalline Aluminum, Science, 2003, 300, p 1275–1277. doi:10.1126/science.1083727

T. Kadoyoshi, H. Kaburaki, F. Shimizu, H. Kimizuka, S. Jitsukawa, and J. Li, Molecular Dynamics Study on the Formation of Stacking Fault Tetrahedra and Unfaulting of Frank Loops in fcc Metals, Acta Mater., 2007, 55, p 3073–3080. doi:10.1016/j.actamat.2007.01.010

E. Martínez, J. Marian, A. Arsenlis, M. Victoria, and J.M. Perlado, Atomistically Informed Dislocation Dynamics in fcc Crystals, J. Mech. Phys. Solids, 2008, 56, p 869–895. doi:10.1016/j.jmps.2007.06.014

K. Sieradzki, A. Rinaldi, C. Friesen, and P. Peralta, Length Scales in Crystal Plasticity, Acta Mater., 2006, 54, p 4533–4538. doi:10.1016/j.actamat.2006.05.041

T. Zhu, J. Li, A. Samanta, A. Leach, and K. Gall, Temperature and Strain-Rate Dependence of Surface Dislocation Nucleation, Phys. Rev. Lett., 2008, 100, p 1–4. doi:10.1103/PhysRevLett.100.025502

S.H. Oh, M. Legros, D. Kiener, and G. Dehm, In Situ Observation of Dislocation Nucleation and Escape in a Submicrometre Aluminium Single Crystal, Nat. Mater., 2009, 8, p 95–100. doi:10.1038/nmat2370

P. Li, Y. Yang, X. Luo, N. Jin, G. Liu, and Z. Feng, Effect of Rate Dependence of Crack Propagation Processes on Amorphization in Al, Mater. Sci. Eng., A, 2017, 684, p 71–77

S. Huang, S. Zhang, T. Belytschko, S.S. Terdalkar, and T. Zhu, Mechanics of Nanocrack: Fracture, Dislocation Emission, and Amorphization, J. Mech. Phys. Solids, 2009, 57, p 840–850

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gupta, P., Yedla, N. Dislocation and Structural Studies at Metal–Metallic Glass Interface at Low Temperature. J. of Materi Eng and Perform 26, 5694–5704 (2017). https://doi.org/10.1007/s11665-017-3026-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-3026-7