Abstract

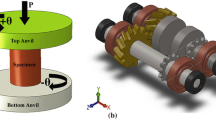

Simultaneous torsion and tension deformation (STTD) modes were applied on commercial pure copper to investigate the influence of stress triaxiality on microstructure evolution and hardness distribution at room temperature. STTD was divided into pure torsion (PT, a special STTD) and general STTD according to tension loading. Microstructure evolution was observed by optical microscopy, electron backscattering diffraction and transmission electron microscopy. The microhardness distribution was measured on the cross section, and the fracture morphology was observed by scanning electron microscopy. Microstructure observations show that ultrafine grains are separated by high-angle grain boundaries. Microhardness measurements exhibit hardness increased more significantly and uniformly in the specimen processed by general STTD mode than PT mode. Additionally, the fracture morphology indicates the fracture mechanism is different between STTD and PT.

Similar content being viewed by others

References

R.Z. Valiev, R.K. Islamgaliev, and I.V. Alexandrov, Bulk Nanostructured Materials From Severe Plastic Deformation, Prog. Mater Sci., 2000, 45(2), p 103–189

M. Zehetbauer and V. Seumer, Cold Work Hardening in Stages IV and V of F.C.C. Metals—I. Experiments and Interpretation, Acta Metallurgica et Materialia, 1993, 41(2), p 577–588

T. Ungár et al., Dislocation Structure and Work Hardening in Polycrystalline ofhc Copper Rods Deformed by Torsion and Tension, Acta Metall., 1986, 34(7), p 1257–1267

A.P. Zhilyaev and T.G. Langdon, Using High-Pressure Torsion for Metal Processing: Fundamentals and Applications, Prog. Mater Sci., 2008, 53(6), p 893–979

S.V. Noor et al., Inhomogeneity in Microstructure and Mechanical Properties During Twist Extrusion, Mater. Sci. Eng. A, 2015, 652, p 186–191

G. Sakai et al., Developing High-Pressure Torsion for Use with Bulk Samples, Mater. Sci. Eng., A, 2005, 406(1), p 268–273

G. Sakai, Z. Horita, and T.G. Langdon, Grain Refinement and Superplasticity in an Aluminum Alloy Processed by High-Pressure Torsion, Mater. Sci. Eng. A, 2005, 393(s 1–2), p 344–351

N. Guo et al., Improving Tensile and Compressive Properties of Magnesium Alloy Rods via a Simple Pre-torsion Deformation, Mater. Des., 2015, 83, p 270–275

N. Guo et al., Enhancing Tensile Strength of Cu by Introducing Gradient Microstructures via a Simple Torsion Deformation, Mater. Des., 2015, 90, p 545–550

K. Rodak and J. Pawlicki, Effect of Compression with Oscillatory Torsion Processing on Structure and Properties of Cu, J. Mater. Sci. Technol., 2011, 27(11), p 1083–1088

K. Rodak and J. Pawlicki, Microstructure Characterization of Cu Processed by Compression with Oscillatory Torsion, Mater. Charact., 2014, 94(8), p 37–45

V. Segal, Slip Line Solutions, Deformation Mode and Loading History During Equal Channel Angular Extrusion, Mater. Sci. Eng. A, 2003, 345(1), p 36–46

J. Li et al., Micro-structural Evolution Subjected to Combined Tension-Torsion Deformation for Pure Copper, Mater. Sci. Eng. A, 2014, 610(29), p 181–187

C. Wang et al., Experimental Microindentation of Pure Copper Subjected to Severe Plastic Deformation by Combined Tension-Torsion, Mater. Sci. Eng. A, 2013, 571(4), p 95–102

Korneva, A., et al. Gradient Microstructure of FeCr30Co8 Hard Magnetic Alloy Subjected to Plastic Deformation by Complex Loading. In: Materials Science Forum. 2011. Trans Tech Publ.

A. Korneva et al., Effect of Deformation Temperature on the Microstructure of Hard Magnetic FeCr22Co15 Alloy Subjected to Tension Combined with Torsion Deformation Modes, Arch. Metall. Mater., 2013, 58(2), p 383–386

A. Korneva, et al. Microstructure of Hard Magnetic FeCr22Co15 Alloy Subjected to Tension Combined with Torsion at High Temperatures. In: Solid State Phenomena. 2013. Trans Tech Publ.

A. Korneva et al., Microstructure Evolution and Magnetic Properties of Hard Magnetic FeCr22Co15 Alloy Subjected to Tension Combined with Torsion, J. Alloys Compd., 2014, 615, p S300–S303

M. Degtyrev, T. Chashuhina, and L. Voronova, VP Pily Ugin, Phys. Met. Metallogr., 2000, 90, p 83–90

C. Zhang, Z. Liu, and G. Wang, Effects of Hot Rolled Shear Bands on Formability and Surface Ridging of an Ultra Purified 21% Cr Ferritic Stainless Steel, J. Mater. Process. Technol., 2011, 211(6), p 1051–1059

A.P. Zhilyaev, S.N. Sergeev, and T.G. Langdon, Electron Backscatter Diffraction (EBSD) Microstructure Evolution in HPT Copper Annealed at a Low Temperature, J. Mater. Res. Technol., 2014, 3(2), p 338–343

A. Hohenwarter, Incremental High Pressure Torsion as a Novel Severe Plastic Deformation Process: Processing Features and Application to Copper, Mater. Sci. Eng. Struct. Mater. Prop. Microstruct. Process., 2015, 626, p 80–85

Y. Ivanisenko et al., High Pressure Torsion Extrusion as a New Severe Plastic Deformation Process, Mater. Sci. Eng. A, 2016, 664, p 247–256

Acknowledgments

The authors are very grateful for the support received from the National Natural Science Foundation of China (Grant No. 51275414), the Fundamental Research Funds for the Central Universities with Grant No. 3102015BJ (II) ZS007, the Aeronautical Science Foundation of China (Grant No. 2011ZE53059), and the Research Fund of the State Key Laboratory of Solidification Processing (NWPU), China (Grant No. 130-QP-2015).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, C., Li, F., Li, J. et al. Influence of Deformation Stress Triaxiality on Microstructure and Microhardness of Pure Copper Processed by Simultaneous Torsion and Tension. J. of Materi Eng and Perform 26, 4104–4111 (2017). https://doi.org/10.1007/s11665-017-2797-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2797-1