Abstract

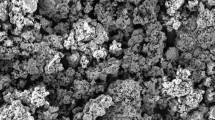

The performance of dry self-lubricating bulk materials is directly related to microstructural aspects such as solid lubricant chemical composition and distribution. In this paper, dry powder mixtures were prepared from iron powder and 9-16.5 vol.% of solid lubricants (graphite and MoS2), both combined and isolated. The results showed that interactions and reactions occurred during processing, either between the solid lubricants or between the lubricants and the matrix, generating carbides and sulfides. On account of that, the lubricant distribution in the microstructure is greatly altered, and the microhardness, friction coefficient and wear rate are increased. The best results were achieved by adequate powder particle size, solid lubricant content and sintering temperature control. In the composite containing 9%MoS2 + 2.5%C, values of friction coefficient and wear rate lower than 0.08 and 8 × 10−6 mm3 N−1 m−1 were reached.

Similar content being viewed by others

References

C. Donnet and A. Erdemir, Historical Developments and New Trends in Tribological and Solid Lubricant Coatings, Surface and Coatings Technology, 2004, 180–181, p 76–84

A. Erdemir, Review of Engineered Tribological Interfaces for Improved Boundary Lubrication, Tribology International, 2005, 38(3), p 249–256

D.A. Lelonis, J.W. Tereshko, and C.M. Andersen, Boron Nitride Powder a High-Performance Alternative for Solid Lubrication, Momentive Performance Materials Inc., New York, 2006

J.P.G. Farr, Molybdenum Disulphide in Lubrication. A Review, Wear, 1975, 35(1), p 1–22

K.R. Campos, P. Kapsa, C. Binder, A.N. Klein, and J.D.B. de Mello, Tribological Evaluation of Self-lubricating Sintered Steels, Wear, 2015, 332, p 932–940

J.D.B. de Mello, C. Binder, G. Hammes, and A.N. Klein, Effect of the Metallic Matrix on the Sliding Wear of Plasma Assisted Debinded and Sintered MIM Self-lubricating Steel, Wear, 2013, 301(1–2), p 648–655

R. Schroeder, A.N. Klein, C. Binder, and J.D.B. de Mello, Internal Lubricant as an Alternative to Coating Steels, Met. Powder Rep., 2010, 65(7), p 24–31

B.S. Ünlü, Tribological and Mechanical Properties of PM Journal Bearings, Powder Metal., 2011, 54(3), p 338–342

V.V. Merie, V.C. Cândea, and C.O. Popa, The Influence of Nickel Content on the Properties of Fe-based Friction Composite Materials, Metal. Int., 2011, 16(4), p 93–96

S.S. Yilmaz, B.S. Ünlü, and R. Varol, Effect of Boronizing and Shot Peening in Ferrous Based FeCu–Graphite Powder Metallurgy Material on Wear, Microstructure and Mechanical Properties, Mater. Des., 2010, 31(9), p 4496–4501

S. Dhanasekaran and R. Gnanamoorthy, Microstructure, Strength and Tribological Behavior of Fe–C–Cu–Ni Sintered Steels Prepared with MoS2 Addition, J. Mater. Sci., 2007, 42(12), p 4659–4666 ((in English))

Y. Watanabe, Sliding Contact Characteristics Between Composite-Materials Containing Layered Solid Lubricants and Carbon, Wear, 1992, 155(2), p 237–249

X.H. Zhang, J.J. Liu, and B.L. Zhu, The Tribological Performance of Ni/MoS2 Composite Brush-Plating Layer in Vacuum, Wear, 1992, 157(2), p 381–387

B. Dubrujeaud, M. Vardavoulias, and M. Jeandin, The Role of Porosity in the Dry Sliding Wear of a Sintered Ferrous Alloy, Wear, 1994, 174(1–2), p 155–161

M. Chandrasekaran and P. Singh, Sintered Iron-Based Antifriction Materials with Added Beta-SiC, Wear, 1997, 206(1–2), p 1–7 ((in English))

Y.X. Wu, F.X. Wang, Y.Q. Cheng, and N.P. Chen, A Study of the Optimization Mechanism of Solid Lubricant Concentration in Ni/MoS2 Self-lubricating Composite, Wear, 1997, 205(1–2), p 64–70

M. Chandrasekaran and P. Singh, Sintered Iron–Copper–Tin–Lead Antifriction Materials—Effect of Temperature, Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process., 2000, 292(1), p 26–33 ((in English))

G. Straelini and A. Molinari, Dry Sliding Wear of Ferrous PM Materials, Powder Metal., 2001, 44(3), p 248–252

S. Dhanasekaran and R. Gnanamoorthy, Dry Sliding Friction and Wear Characteristics of Fe–C–Cu Alloy Containing Molybdenum di Sulphide, Materials & Design, 2007, 28(4), p 1135–1141

S. Dhanasekaran and R. Gnanamoorthy, Gear Tooth Wear in Sintered Spur Gears under Dry Running Conditions, Wear, 2008, 265(1–2), p 81–87

J.L. Li, D.S. Xiong, and M.F. Huo, Friction and Wear Properties of Ni–Cr–W–Al–Ti–MoS2 at Elevated Temperatures and Self-consumption Phenomena, Wear, 2008, 265(3–4), p 566–575

Y. Watanabe, High-Speed Sliding Characteristics of Cu-Sn-based Composite Materials Containing Lamellar Solid Lubricants by Contact Resistance Studies, Wear, 2008, 264(7–8), p 624–631

M. Xue, High Temperature Oxidation and Wear Behaviour of Powder Metallurgically Developed Ni–Cr–W–Al–Ti–MoS2 Composite, Indian J. Eng. Mat. Sci., 2009, 16(2), p 111–115

A.G. Kostornov, O.I. Fushchich, V.F. Gorban, T.M. Chevychelova, M.V. Karpets, and A.Y. Koval, Service Properties of Cu–Sn–CuWO4–MoS2 Composite and Micromechanical Characteristics of its Friction Surface, Powder Metall. Met. Ceram., 2011, 49(11–12), p 647–653

C. Teisanu and S. Gheorghe, Development of New PM Iron-Based Materials for Self-Lubricating Bearings, Adv. Tribol., 2011, 2011, p 11

S.A. Alidokht, A. Abdollah-Zadeh, and H. Assadi, Effect of Applied Load on the Dry Sliding Wear Behaviour and the Subsurface Deformation on Hybrid Metal Matrix Composite, Wear, 2013, 305(1–2), p 291–298

I.N. Popescu, C. Ghita, V. Bratu, and G.P. Navarro, Tribological Behaviour and Statistical Experimental Design of Sintered Iron–Copper Based Composites, Appl. Surf. Sci., 2013, 285, p 72–85

B. Juszczyk, J. Kulasa, S. Malara, M. Czepelak, W. Malec, B. Cwolek, and L. Wierzbicki, Tribological Properties of Copper-Based Composites with Lubricating Phase Particles, Arch. Metall. Mater., 2014, 59(2), p 615–620

X. Shi, W. Zhai, M. Wang, Z. Xu, J. Yao, S. Song, and Y. Wang, Tribological Behaviors of NiAl Based Self-lubricating Composites Containing Different Solid Lubricants at Elevated Temperatures, Wear, 2014, 310(1–2), p 1–11

X. Shi, W. Zhai, Z. Xu, M. Wang, J. Yao, S. Song, and Y. Wang, Synergetic Lubricating Effect of MoS2 and Ti3SiC2 on Tribological Properties of NiAl Matrix Self-Lubricating Composites Over a Wide Temperature Range, Materials & Design, 2014, 55, p 93–103

Z. Xu, X. Shi, Q. Zhang, W. Zhai, X. Li, J. Yao, L. Chen, Q. Zhu, and Y. Xiaov, Effect of Sliding Speed and Applied Load on Dry Sliding Tribological Performance of TiAl Matrix Self-lubricating Composites, Tribol. Lett., 2014, 55(3), p 393–404

S.-X. Chen, Y. Feng, S. Li, and Y.-J. Xie, Influences of MoS2 Contents on Sintering Process and Properties of Cu-MoS2 Composites, J. Mater. Sci. Eng., 2008, 2(12), p 7–12

A.M. Kovalchenko, O.I. Fushchich, and S. Danyluk, The Tribological Properties and Mechanism of Wear of Cu-based Sintered Powder Materials Containing Molybdenum Disulfide and Molybdenum Diselenite Under Unlubricated Sliding Against Copper, Wear, 2012, 290, p 106–123

A.G. Kostornov, O.I. Fushchich, T.M. Chevychelova, and O.D. Kostenko, Sintering of Cu–Sn–P–MoS2 Powder Samples at 780 °C, Powder Metall. Met. Ceram., 2014, 52(11–12), p 651–655

D.S. Xiong, Lubrication Behavior of Ni–Cr-Based Alloys Containing MoS2 at High Temperature, Wear, 2001, 251(1–12), p 1094–1099

J.L. Li and D.S. Xiong, Tribological Properties of Nickel-Based Self-Lubricating Composite at Elevated Temperature and Counterface Material Selection, Wear, 2008, 265(3–4), p 533–539

I.G. Slys’, A.V. Perepelkin, and I.M. Fedorchenko, Structure and Properties of Sintered Stainless Steel Containing Molybdenum Disulfide, Powder Metall. Met. Ceram., 1973, 12(9), p 710–714

S. Raadnui, S. Mahathanabodee, and R. Tongsri, Tribological Behaviour of Sintered 316L Stainless Steel Impregnated with MoS2 Plain Bearing, Wear, 2008, 265(3–4), p 546–553

C. Binder, G. Hammes, R. Schroeder, A.N. Klein, J.D.B. de Mello, R. Binder, and W.R. Junior, ‘Fine tuned’ Steels Point the Way to a Focused Future, Met. Powder Rep., 2010, 65(4), p 29–37

S. Torquato, Random Heterogeneous Materials: Microstructure and Macroscopic Properties, Springer Science & Business Media, Berlin, 2013

C.J. Smithells, Metals Reference Book, 5th ed., Butterworths, London, 1976, p XIV, 1566

Introduction to Quantitative Metallography. http://vacaero.com/information-resources/metallography-with-george-vander-voort/1136-introduction-to-quantitative-metallography.html. Accessed 23-Sept-2015

K.P. Furlan, J.Z. de Assunção, G. Paz, C. Binder, and A.N. Klein, Sintering Studies and Microstructural Evolution of Fe-MoS2 Mixtures, Mater. Res., 2014, 802, p 415–420

K.P. Furlan, C. Binder, A.N. Klein, and J.D.B. de Mello, Thermal Stability of the MoS2 Phase in Injection Moulded 17-4 PH Stainless Steel, J. Mater. Res. Technol., 2012, 1, p 134–140

S.C. Lim, M. Gupta, and W.B. Ng, Friction and Wear Characteristics of Al–Cu/C Composites Synthesized using Partial Liquid Phase Casting Process, Mater. Des., 1997, 18(3), p 161–166

R.M. German, Powder Metallurgy of Iron and Steel, Wiley, New York, 1998

N. Ohmae, Influence of Atomic Oxygen on Space Tribology in a Low-Earth-Orbit, Wear, 1993, 168(1–2), p 99–103

A. Erdemir, Solid Lubricants and Self-Lubricating Films, Modern Tribology Handbook, v. 2 - Materials, Coating, and Industrial Applications, 2nd ed., B. Bhushan, Ed., CRC Press, 2001

J.K. Lancaster, A Review of the Influence of Environmental Humidity and Water on Friction, Lubrication and Wear, Tribol. Int., 1990, 23(6), p 371–389

Acknowledgments

The present work was developed with financial aid from CNPq (Conselho Nacional de Desenvolvimento Científico e Tecnológico—Brazil) Grant No. 163569/2014-2, Whirlpool and BNDES. Special thanks to Höganäs Brazil for powder’s donations. Research was supported by LCME-UFSC.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Furlan, K.P., da Costa Gonçalves, P., Consoni, D.R. et al. Metallurgical Aspects of Self-lubricating Composites Containing Graphite and MoS2 . J. of Materi Eng and Perform 26, 1135–1145 (2017). https://doi.org/10.1007/s11665-017-2563-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2563-4