Abstract

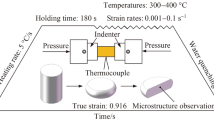

A reasonable constitutive model is the key to achieving the accurate numerical simulation of magnesium alloy extrusion process. Based on the hot compression tests of the as-extruded AZ31 magnesium alloy, the strain-compensated Arrhenius equation, the constitutive equation taking into account dynamic recovery (DRV) and dynamic recrystallization (DRX), and the modified Fields-Backofen equation (FB) are established to describe the deformation behavior of this alloy under large strain condition (strain level greater than 1.0) and wide strain rate range (0.01 to 10 s−1), respectively. Then material parameters in each constitutive model are determined by linear fitting method. The comparison of these three kinds of equations shows that the strain-compensated Arrhenius model provides the best prediction of flow stress, and the calculated value of correlation coefficient (R) is the highest as 0.9945 and the average absolute relative error (AARE) is the lowest as 3.11%. The constitutive equation with DRV + DRX can also predict flow stress accurately, and its values of R and AARE are 0.9920 and 4.41%, respectively. However, compared to the other two constitutive equations, the modified FB equation does not give good description of hot deformation behavior for this magnesium alloy. Finally, the advantages and drawbacks of these three kinds of constitutive models are discussed and compared. Therefore, this work could provide theoretical guidelines for investigating hot deformation behavior of wrought magnesium alloys and determining the appropriate extrusion process parameters under large strain condition.

Similar content being viewed by others

References

Y. Liu, S.L. Cai, and L.H. Dai, A New Method for Grain Refinement in Magnesium Alloy: High Speed Extrusion Machining, Mater. Sci. Eng. A, 2016, 651, p 878–885

C.J. Bettles and M.A. Gibson, Current Wrought Magnesium Alloys: Strengths and Weaknesses, JOM, 2005, 57, p 46–49

L.W. Lu, T.M. Liu, J. Chen, and Z.C. Wang, Microstructure and Corrosion Behavior of AZ31 Alloys Prepared by Dual Directional Extrusion, Mater. Des., 2012, 36, p 687–693

K.S. Choi, E.I. Barker, G. Cheng, X. Sun, J.H. Forsmark, and M. Li, Predicting Stress vs Strain Behaviors of Thin-Walled High Pressure Die Cast Magnesium Alloy with Actual Pore Distribution, SAE Int., 2016, 01, p 0290

G. Cheng, E.I. Barker, E.V. Stephens, K.S. Choi, X. Sun (2016) Quantifying Grain Level Stress-Strain Behavior for AM40 Via Instrumented Microindentation. MRS Adv. p 1–12

A. Jäger, V. Gärtnerova, and K. Tesař, Microstructure and Anisotropy of the Mechanical Properties in Commercially Pure Titanium After Equal Channel Angular Pressing with Back Pressure at Room Temperature, Mater. Sci. Eng. A, 2015, 644, p 114–120

S.R. Kumar, K. Gudimetla, P. Venkatachalam, B. Ravisankar, and K. Jayasankar, Microstructural and Mechanical Properties of Al 7075 Alloy Processed by Equal Channel Angular Pressing, Mater. Sci. Eng. A, 2012, 533, p 50–54

M.H. Shaeri, M.T. Salehi, S.H. Seyyedein, M.R. Abutalebi, and J.K. Park, Characterization of Microstructure and Deformation Texture During Equal Channel Angular Pressing of Al-Zn-Mg-Cu Alloy, J Alloys Compd., 2013, 576, p 350–357

Y.F. Shen, R.G. Guan, Z.Y. Zhao, and R.D.K. Misra, Ultrafine-Grained Al-0.2Sc-0.1Zr Alloy: The Mechanistic Contribution of Nano-sized Precipitates on Grain Refinement During the Novel Process of Accumulative Continuous Extrusion, Acta Mater., 2015, 100, p 247–255

Y.Z. Du, M.Y. Zheng, X.G. Qiao, K. Wu, X.D. Liu, G.J. Wang, X.Y. Lv, M.J. Li, X.L. Liu, Z.J. Wang, and Y.T. Liu, The Effect of Double Extrusion on the Microstructure and Mechanical Properties of Mg-Zn-Ca Alloy, Mater. Sci. Eng. A, 2013, 583, p 69–77

Y.Z. Du, M.Y. Zheng, C. Xu, X.G. Qiao, K. Wu, X.D. Liu, G.J. Wang, and X.Y. Lv, Microstructures and Mechanical Properties of As-Cast and As-Extruded Mg-4.50Zn-1.13Ca (wt%) Alloys, Mater. Sci. Eng. A, 2013, 576, p 6–13

Y.Z. Wu, H.G. Yan, J.H. Chen, S.Q. Zhu, B. Su, and P.L. Zeng, Hot Deformation Behavior and Microstructure Evolution of ZK21 Magnesium Alloy, Mater. Sci. Eng. A, 2010, 527, p 3670–3675

L.F. Liu and H.L. Ding, Study of the Plastic Flow Behaviors of AZ91 Magnesium Alloy During Thermomechanical Processes, J Alloys Compd., 2009, 484, p 949–956

G.Z. Quan, Y. Shi, Y.X. Wang, B.S. Kang, T.W. Ku, and W.J. Song, Constitutive Modeling for the Dynamic Recrystallization Evolution of AZ80 Magnesium Alloy Based on Stress-Strain Data, Mater. Sci. Eng. A, 2011, 528, p 8051–8059

H.Y. Wu, J.C. Yang, F.J. Zhu, and C.T. Wu, Hot Compressive Flow Stress Modeling of Homogenized AZ61 Mg Alloy Using Strain-Dependent Constitutive Equations, Mater. Sci. Eng. A, 2013, 574, p 17–24

D.H. Yu, Modeling High-Temperature Tensile Deformation Behavior of AZ31B Magnesium Alloy Considering Strain Effects, Mater. Des., 2013, 51, p 323–330

Z.W. Cai, F.X. Chen, and J.Q. Guo, Constitutive Model for Elevated Temperature Flow Stress of AZ41M Magnesium Alloy Considering the Compensation of Strain, J Alloys Compd., 2015, 678, p 215–222

Y.J. Qin, Q.L. Pan, Y.B. He, W.B. Li, X.Y. Liu, and X. Fan, Modeling of Flow Stress for Magnesium Alloy During Hot Deformation, Mater. Sci. Eng. A, 2010, 527, p 2790–2797

H. Takuda, T. Morishita, T. Kinoshita, and N. Shirakawa, Modelling of Formula for Flow Stress of a Magnesium Alloy AZ31 Sheet at Elevated Temperatures, J. Mater. Process. Technol., 2005, 164–165, p 1258–1262

L.C. Tsao, Y.T. Huang, and K.H. Fan, Flow Stress Behavior of AZ61 Magnesium Alloy During Hot Compression Deformation, Mater. Des., 2014, 53, p 865–869

X. Shang, J. Zhou, X. Wang, and Y. Luo, Optimizing and Identifying the Process Parameters of AZ31 Magnesium Alloy in Hot Compression on the Base of Processing Maps, J Alloys Compd., 2015, 629, p 155–161

R. Bhattacharya, Y.J. Lan, B.P. Wynne, B. Davis, and W.M. Rainforth, Constitutive Equations of Flow Stress of Magnesium AZ31 Under Dynamically Recrystallizing Conditions, J. Mater. Process. Tech., 2014, 214, p 1408–1417

Y.C. Lin and X.M. Chen, A Critical Review of Experimental Results and Constitutive Descriptions for Metals and Alloys in Hot Working, Mater. Des., 2011, 32, p 1733–1759

P. Changizian, A. Zarei-Hanzaki, and A.A. Roostaei, The High Temperature Flow Behavior Modeling of AZ81 Magnesium Alloy Considering Strain Effects, Mater. Des., 2012, 39, p 384–389

R. Ebrahimi and A. Najafizadeh, A New Method for Evaluation of Friction in Bulk Metal Forming, J. Mater. Process. Technol., 2004, 152, p 136–143

N.Q. Peng, G.B. Tang, and Z.D. Liu, Correcting Method of Flow Stress Curve for Hot Compression, Hot Working Technol., 2012, 41, p 12–15

J.J. Jonas, C.M. Sellars, and W.J.M. Tegart, Strength and Structure Under Hot-Working Conditions, Metall. Rev., 1969, 14, p 1–24

C. Zener and J.H. Hollomon, Effect of Strain Rate Upon Plastic Flow of Steel, J. Appl. Phys., 1944, 15(1), p 22–32

N. Haghdadi, A. Zarei-Hanzaki, and H.R. Abedi, The Flow Behavior Modeling of Cast A356 Aluminum Alloy at Elevated Temperatures Considering the Effect of Strain, Mater. Sci. Eng. A, 2012, 535, p 252–257

Y.Y. Dong, C.S. Zhang, G.Q. Zhao, Y.J. Guan, A.J. Gao, and W.C. Sun, Constitutive Equation and Processing Maps of an Al-Mg-Si Aluminum Alloy: Determination and Application in Simulating Extrusion Process of Complex Profiles, Mater. Des., 2016, 92, p 983–997

Y.C. Lin, D.X. Wen, J. Deng, G. Liu, and J. Chen, Constitutive Models for High-Temperature Flow Behaviors of a Ni-Based Superalloy, Mater. Des., 2014, 59, p 115–123

Y.C. Lin, K.K. Li, H.B. Li, J. Chen, X.M. Chen, and D.X. Wen, New Constitutive Model for High-Temperature Deformation Behavior of Inconel 718 Superalloy, Mater. Des., 2015, 74, p 108–118

Y.C. Lin, M.S. Chen, and J. Zhong, Prediction of 42CrMo Steel Flow Stress at High Temperature and Strain Rate, Mech. Res. Commun., 2008, 35, p 142–150

D.S. Fields and W.A. Bachofen, Determination of Strain Hardening Characteristics by Torsion Testing, ASTM Proc. Am. Soc. Test. Mater., 1957, 57, p 1259–1272

Y.Q. Cheng, H. Zhang, Z.H. Chen, and K.F. Xian, Flow Stress Equation of AZ31 Magnesium Alloy Sheet During Warm Tensile Deformation, J. Mater. Process. Technol., 2008, 208, p 29–34

Acknowledgments

The authors would like to acknowledge the financial support from National Natural Science Foundation of China (51575315), China Postdoctoral Science Foundation (2014M560551), Fund of the State Key Laboratory of Solidification Processing in NWPU (SKLSP201303), and Fundamental Research Funds of Shandong University (2015WLJH29).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dong, Y., Zhang, C., Lu, X. et al. Constitutive Equations and Flow Behavior of an As-Extruded AZ31 Magnesium Alloy Under Large Strain Condition. J. of Materi Eng and Perform 25, 2267–2281 (2016). https://doi.org/10.1007/s11665-016-2092-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2092-6