Abstract

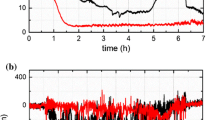

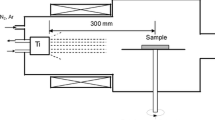

Microtribology experiments were carried out on the W1−x Al x N films, deposited by radio frequency magnetron reactive sputtering on 304 stainless steel substrates and Si(100). Film wear mechanisms were investigated from the evolution of the friction coefficient and scanning electron microscopy observations. The results show that the WAlN films consist of a mixture of face-centered cubic W(Al)N and hexagonal wurtzite structure AlN phases and the preferred orientation changes from (111) to (200). The film damage after sliding test is mainly attributed to the composition and microstructure of the films. The amount of debris generated by friction is linked to the crack resistance. The better tribological properties for W1−x Al x N films (x < 0.4) are mainly determined by the higher toughness.

Similar content being viewed by others

References

S.D. Kim, Microstructural Properties of Plasma-Enhanced Chemical Vapor Deposited WN x Films Using WF6-H2-N2 Precursor System, Curr. Appl. Phys., 2007, 7, p 426–433

M.T. Hosseinnejad, M. Ghoranneviss, G.R. Etaati, M. Shirazi, and Z. Ghorannevis, Deposition of Tungsten Nitride Thin Films by Plasma Focus Device at Different Axial and Angular Positions, Appl. Surf. Sci., 2011, 257, p 7653–7658

J. Zuo, Y. Xie, J. Zhang, Q.P. Wei, B. Zhou, J.Q. Luo, Y.J. Wang, Z.M. Yu, and Z.G. Tang, TiN Coated Stainless Steel Bracket: Tribological, Corrosion Resistance, Biocompatibility and Mechanical Performance, Surf. Coat. Tech., 2015, 277, p 227–233

A.Z. Abidin, R. Kozera, M. Höhn, I. Endler, M. Knaut, A. Boczkowska, A. Czulak, P. Malczyk, N. Sobczak, and A. Michaelis, Preparation and Characterization of CVD-TiN-Coated Carbon Fibers for Applications in Metal Matrix Composites, Thin Solid Films, 2015, 589, p 479–486

S. Veprek and S. Reiprich, A Concept for the Design of Novel Superhard Coatings, Thin Solid Films, 1995, 268, p 64–71

C.Y. Yu, S.B. Wang, X.B. Yin, and B.S. Xu, Study on High-Temperature Oxidation Resistance of CrAlN Coating, Rare Met. Mater. Eng., 2009, 38, p 1015–1018

Z.F. Zhou, P.L. Tam, P.W. Shum, and K.Y. Li, High Temperature Oxidation of CrTiAlN Hard Coatings Prepared by Unbalanced Magnetron Sputtering, Thin Solid Films, 2009, 517, p 5243–5247

J. Lin, B. Mishra, J.J. Moore, and W.D. Sproul, A Study of the Oxidation Behavior of CrN and CrAlN Thin Films in Air Using DSC and TGA Analyses, Surf. Coat. Tech., 2008, 202, p 3272–3283

J.H. Hsieh, L.K. Tana, and X.T. Zeng, Oxidation and Wear Behaviors of Ti-Based Thin Films, Surf. Coat. Tech., 2006, 201, p 4094–4098

X.Z. Ding and X.T. Zeng, Structural, Mechanical and Tribological Properties of CrAlN Coatings Deposited by Reactive Unbalanced Magnetron Sputtering, Surf. Coat. Tech., 2005, 200, p 1372–1376

K.H. Kim and B.H. Park, Mechanical Properties and Oxidation Behavior of TiSiN Films Prepared by Plasma-Assisted CVD, Chem. Vapor Depos., 1999, 5, p 275–279

D. Li, Synthesis of ZrAlN Coatings with Thermal Stability at High Temperature, Sci. China Ser. E, 2006, 49, p 576–581

P. Henry, M.J. Pac, C. Rousselot, and M.H. Tuilier, Wear Mechanisms of Titanium and Aluminium Nitride Coatings: A microtribological Approach, Surf. Coat. Tech., 2013, 223, p 79–86

I.L. Singer, S. Fayeulle, and P.D. Ehni, Friction and Wear Behavior of TiN in Air: The Chemistry of Transfer Films and Debris Formation, Wear, 1991, 149, p 375–394

L.H. Yu, H.J. Zhao, and J.H. Xu, Mechanical, Tribological and Corrosion Performance of WBN Composite Films Deposited by Reactive Magnetron Sputtering, Appl. Surf. Sci., 2014, 315, p 380–386

L.H. Yu, R. Wang, and J.H. Xu, Effects of Negative Bias Voltage on Tribological Properties of W-C-N Thin Films by Magnetron Sputtering, Trans. Mater. Heat Treat., 2013, 34, p 166–171

H.J. Zhao and L.H. Yu, Microstructure and Properties of WAlN Composite Film Fabricated by Magnetron Sputtering, Mater. Sci. Eng. Powder Metal., 2015, 2, p 288–295

J.F. Yang, Y. Jiang, Z.Q. Yuan, X.P. Wang, and Q.F. Fang, Effect of Carbon Content on the Microstructure and Properties of WSiCN Coatings Fabricated by Magnetron Sputtering, Mater. Sci. Eng. B, 2012, 177, p 1120–1125

B. Subramanian, V. Swaminathan, and M. Jayachandran, Micro-structural and Optical Properties of Reactive Magnetron Sputtered Aluminum Nitride (AlN) Nanostructured Films, Curr. Appl. Phys., 2011, 11, p 43–49

H.W. Hugosson, H. Hogberg, M. Algren, M. Rodmar, and T.I. Selinder, Theory of the Effects of Substitutions on the Phase Stabilities of Ti1−xAlxN, J. Appl. Phys., 2003, 93, p 4505–4511

R.A. Kant, B.D. Sartwell, I.L. Singer, and R.G. Vardiman, Adherent TiN films Produced by Ion Beam Enhanced Deposition at Room Temperature, Nucl. Instrum. Methods B, 1985, 7, p 915–919

G.R. Anstis, P. Chantikul, B.R. Lawn, and D.B. Marshall, A Critical Evaluation of Indentation Techniques for Measuring Fracture Toughness: I, Direct Crack Measurements, J. Am. Ceram. Soc., 1981, 64, p 533–538

M. Girleanu, M.J. Pac, P. Louis, O. Ersen, J. Werckmann, C. Rousselot, and M.H. Tuilier, Characterisation of Nano-structured Titanium and Aluminium Nitride Coatings by Indentation, Transmission Electron Microscopy and Electron Energy Loss Spectroscopy, Thin Solid Films, 2011, 519, p 6190–6195

M. Gîrleanu, M.J. Pac, O. Ersen, J. Werckmann, G. Arnold, C. Rousselot, and M.H. Tuilier, The Role of Structural Properties on Damage Behaviour of Titanium and Aluminium Nitride Coatings: An EXAFS and TEM Study, Surf. Coat. Tech., 2010, 204, p 2042–2045

S. Zhang, S. Deen, Y.Q. Fu, and H.J. Du, Recent Advances of Superhard Nanocomposite Coatings: a Review, Surf. Coat. Technol., 2003, 167, p 113–119

Acknowledgment

This work is supported by the Research Innovation Program for College Graduates of Jiangsu Province (CXZZ13_0718).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, H., Mu, C. & Ye, F. Microtribological Mechanisms of Tungsten and Aluminum Nitride Films. J. of Materi Eng and Perform 25, 1446–1452 (2016). https://doi.org/10.1007/s11665-016-2008-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2008-5