Abstract

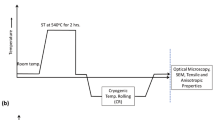

Cryo-cross-rolling (CCR) is a new process that combines the properties of cross-rolling and cryo-rolling. In this study, an Al 1050 sheet was reduced up to 95% of its thickness by rolling in vertical directions for ten passes at cryogenic temperature. This process creates high dislocation density and a nano-subgrain structure. The transmission electron microscopy (TEM) and x-ray diffraction (XRD) analyses show that the grain size is almost 180 nm and the crystallite size is about 47 nm in CCR sample. Scanning electron microscopy observations of fracture surfaces show that the ductility of Al 1050 decreases under the CCR process. The hardness of the sample increased significantly in this process. The results of TEM and XRD performed on crystallite size were in conformity with each other. The strength of specimens was increased and their ductility was decreased by the application of this process.

Similar content being viewed by others

References

Ch Mondal, A.K. Singh, A.K. Mukhopadhyay, and K. Chattopadhyay, Effects of Different Modes of Hot Cross-Rolling in 7010 Aluminium Alloy, Mater. Metals Mater. Soc. ASM Int., 2013, 44A, p 2746–2763

M.Y. Huh, S.Y. Cho, and O. Engler, Randomization of the Annealing Texture in Aluminium 5182 Sheet by Cross-Rolling, Mater. Sci. Eng., 2001, A315, p 35–46

P.S. Bate, Y. Huang, and F.J. Humphreys, Development of the Brass Texture Component During the Hot Deformation of Al-6Cu-0.4Zr, Acta Mater., 2004, 52, p 4281–4289

A. Bocker, H. Klein, and H.J. Bunge, Development of Cross-Rolling Textures in AlMn1, Textures Microstruct., 1990, 12, p 155–174

H. Yu, C. Lu, K. Tieu, X. Liu, Y. Sun, Q. Yu, and C. Kong, Asymmetric Cryorolling for Fabrication of Nanostructural Aluminium Sheets, Sci. Rep. 2012, p 1–5.

D.G. Kim, H.T. Son, D.W. Kim, Y.H. Kim, and K.M. Lee, Effect of Cross-Roll Angle on Microstructures and Mechanical Properties during Cross-Roll Rolling in AZ31 Alloys, Mater. Trans., 2011, 12, p 2274–2277

M.Y. Huh, O. Engler, and D. Raabe, On the Influence of Cross-Rolling on Shear Band Formation and Texture Evolution in Low Carbon Steel Sheets, Textures Microstruct., 1995, 24, p 225–237

Z.L. Xiao, L.F. Shun, and X.H. Bin, Microstructure and Mechanical Properties of Cross-Rolled Ti50Ni47Fe3 Shape Memory Alloy, Chin. J. Aeronaut., 2006, 19, p S224–S227

K.R. Mamaghani and M. Kazemeinezhad, The Effect of Direct and Cross-Rolling on Mechanical Properties and Microstructure of Severely Deformed Aluminium, JMEPEG, 2014, 23, p 115–124

S.H. Kim, H.G. Kang, M.Y. Huh, and O. Engler, Interpretation of the Strain State During Cross-Roll Rolling of Aluminium by Means of Texture Analysis, Mater. Sci. Eng., 2009, 508, p 121–128

Y.W. Tham, M.W. Fu, H.H. Hng, M.S. Yong, and K.B. Lim, Bulk Nanostructured Processing of Aluminium Alloy, J. Mater. Process. Technol., 2007, 192, p 575–581

Q. Lin, X. Huang, D.J. Lloyd, and N. Hansen, Microstructure and Strength of Commercial Purity Aluminium Cold- Rolled to Large Strains, Acta Mater., 2002, 50, p 3789–3802

O.V. Mishin, D.J. Jensn, and N. Hasen, Evolution of Microstructure and Texture During Annealing of Aluminium AA1050 Cold Rolled to High and Ultrahigh Strains, Metall. Mater. Trans A., 2010, 41, p 2936–2948

F.N. Yunusova, R.K. Islamgaliev, M.A. Bardinova, A.R. Kil’mametov, and R.Z. Valiev, Microstructure and Mechanical Properties of Aluminium Alloy 1421 After ECAP and Warm Rolling, Met. Sci. Heat Treat., 2007, 49, p 135–140

K.T. Park, H.J. Lee, C.S. Lee, W.J. Nam, and D.H. Shin, Enhancement of High Strain Rate Superplastic Elongation of a Modified 5154 Al by Subsequent Rolling After Equal Channel Angular Pressing, Scr. Mater., 2004, 51, p 479–483

Sh Malekjani, P.D. Hodgson, N.E. Stanforda, and T.B. Hilditchb, The Role of Shear Banding on the Fatigue Ductility of Ultrafine-Grained Aluminium, Scr. Mater., 2013, 68, p 269–272

Sh Malekjani, P.D. Hodgson, N.E. Stanforda, and T.B. Hilditch, Shear Bands Evolution in Ultrafine-Grained Aluminium Under Cyclic Loading, Scr. Mater., 2013, 68, p 821–824

N.N. Krishna, A.K. Akash, K. Sivaprasad, and R. Narayanasamy, Studies on Void Coalescence Analysis of Nanocrystalline Cryorolled Commercially Pure Aluminium Formed Under Different Stress Conditions, Mater. Des., 2010, 31, p 3578–3584

P.N. Rao and R. Jayaganthan, Effects of Warm Rolling and Ageing After Cryogenic Rolling on Mechanical Properties and Microstructure of Al 6061 Alloy, Mater. Des., 2012, 39, p 226–233

S.K. Panigrahi and R. Jayaganthan, Development of Ultrafine-Grained Al 6063 Alloy by Cryorolling with the Optimized Initial Heat Treatment Conditions, Mater. Des., 2011, 32, p 2172–2180

K.G. Krishnaa, K. Sivaprasad, K. Venkateswarlu, and K.C.H. Kumar, Microstructural Evolution and Aging Behavior of Cryorolled Al–4Zn–2Mg Alloy, Mater. Sci. Eng., 2012, 535, p 129–135

S.K. Panigrahi, R. Jayaganthan, and V. Chawla, Effect of Cryorolling on Microstructure of Al–Mg–Si Alloy, Mater. Lett., 2008, 62, p 2626–2629

S.K. Panigrahi and R. Jayaganthan, Influence of Solutes and Second Phase Particles on Work Hardening Behaviour of Al 6063 Alloy Processed by Cryorolling, Mater. Sci. Eng. A, 2011, 528, p 3147–3160

S.K. Panigrahi and R. Jayaganthan, Effect of Rolling Temperature on Microstructure and Mechanical Properties of 6063 Al Alloy, Mater. Sci. Eng. A, 2008, 492, p 300–305

K.G. Krishnaa, K. Sivaprasad, K. Venkateswarlu, and K.C.H. Kumard, Microstructural Evolution and Aging Behavior of Cryorolled Al–4Zn–2Mg Alloy, Mater. Sci. Eng. A, 2012, 535, p 129–135

S.K. Panigrahi, R. Jayaganthan, and V. Chawla, Effect of Cryorolling on Microstructure of Al–Mg–Si Alloy, Mater. Lett., 2008, 622, p 626–2629

C. Keller, E. Hug, R. Retoux, and X. Feaugas, TEM Study of Dislocation Patterns in Near-Surface and Core Regions of Deformed Nickel Polycrystals with Few Grains Across the Cross Section, Mech. Mater., 2010, 42, p 44–54

Darja Jenko, Stan Mandziej, Caroline Toffolon-Masclet et al., TEM Study of Dislocations in Duplex Stainless Steel, Mater. Technol., 2014, 48(1), p 131–135

P. Landau, R.Z. Shneck, G. Makov, and A. Venkert, In-situ TEM Study of Dislocation Patterning During Deformation in Single Crystal Aluminium, J. Phys., 2010, 241, p 012060

T. UngaÂr, J. Gubicza, G. RibaÂrik, and A. BorbeÂly, Crystallite Size Distribution and Dislocation Structure Determined by Diffraction Profile Analysis: Principles and Practical Application to Cubic and Hexagonal Crystals, J. Appl. Cryst., 2001, 34, p 298–310

I.C. Dragomir, M. Gheorghe, N. Thadhani, and R.L. Snyder, X-Ray Peak Profile Analysis of Crystallite Size Distribution and Dislocation Type and Density Evolution in Nano-structure Cu Obtained by Deformation at Liquid Nitrogen Temperature, Mater. Sci. Eng. A, 2005, 402, p 158–162

Acknowledgment

The authors gratefully acknowledge the financial supports the TEM, SEM, and XRD laboratories of Materials Research School (NSTRI).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Eskandari, M.J., Asadabad, M.A., Tafrishi, R. et al. Evolution of Nanostructure in Al 1050 Sheet Deformed by Cryo-cross-rolling. J. of Materi Eng and Perform 25, 1643–1649 (2016). https://doi.org/10.1007/s11665-016-1971-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-1971-1