Abstract

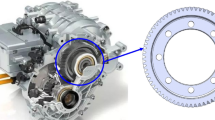

The beneficial effects of using flux concentrators during induction heat treatment process of spur gears made of 4340 high strength steel is demonstrated using 3D finite element model. The model is developed by coupling electromagnetic field and heat transfer equations and simulated by using Comsol software. Based on an adequate formulation and taking into account material properties and process parameters, the model allows calculating temperature distribution in the gear tooth. A new approach is proposed to reduce the electromagnetic edge effect in the gear teeth which allows achieving optimum hardness profile after induction heat treatment. In the proposed method, the principal gear is positioned in sandwich between two other gears having the same geometry that act as flux concentrators. The gap between the gear and the flux concentrators was optimized by studying temperature variation between the tip and root regions of gear teeth. Using the proposed model, it was possible identifying processing conditions that allow for quasi-uniform final temperature profile in the medium and high frequency conditions during induction hardening of spur gears.

Similar content being viewed by others

References

L. Faure, Aspect des dentures d’engrenages après fonctionnement, 2nd ed., Publications CETIM, Paris, France, 1992, p 123

D.W. Dudley, Handbook of Practical Gear Design, CRC Press, Boca Raton, 1994, p 688

D. Tabor, The Hardness of Metals, Clarendon Press, Oxford, 1951, p 423

G.B. Olson and W.S. Owen, Martensite, ASM International, Materials Park, 1992, p 331

J. Grum and J. Mater, A review of the Influence of Grinding Conditions on Resulting Residual Stresses After Induction Surface Hardening and Grinding, Processing Technol. Proc., 2001, 114, p 212–226

N. Barka, A. Chebak, A. El Ouafi, P. Bocher, and J. Brousseau, Study of Induction Heating Process Applied to Internal Gear Using 3D Simulation, Appl. Mech. Mater., 2012, 232, p 730–735

N. Barka, P. Bocher, and J. Brousseau, Sensitivity Study of Hardness Profile of 4340 Specimen Heated by Induction Process Using Axi-symmetric Modeling, Int. J. Adv. Manuf. Technol., 2013, 69, p 2747–2756

N. Barka, A. Chebak, and J. Brousseau, Optimization of Hardness Profile of Bearing Seating Heated by Induction Process Using Axisymmetric Simulation, Piers Online, 2011, 7, p 316–320

V. Rudnev, D. Loveless, R. Cook, and M. Black, Handbook of Induction Heating, Marcell Dekker Inc., New York, 2003

Y. Favennec, V. Labbe, and F. Bay, Induction Heating Processes Optimization a General Optimal Control Approach, J. Comput. Phys., 2003, 187, p 68–94

J. Yuan, J. Kang, Y. Rong, and R.D. Sisson, Jr., FEM Modeling of Induction Hardening Processes in Steel, J. Mater. Eng. Perform., 2003, 12, p 589–596

S. Zinn, Elements of Induction Heating: Design, Control, and Applications, ASM International, Metals Park, OH, 1988

N. Barka, “Étude de sensibilité du profil de dureté des engrenages droits traités thermiquement par induction en fonction des paramètres machines,” École de technologie supérieure de Montréal, Ph.D. Thesis, p. 199, 2011.

W.D. Callister and D.G. Rethwisch, Fundamentals of Materials Science and Engineering, Wiley, New York, 2008, p 879

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Barka, N., Chebak, A., El Ouafi, A. et al. A New Approach in Optimizing the Induction Heating Process Using Flux Concentrators: Application to 4340 Steel Spur Gear. J. of Materi Eng and Perform 23, 3092–3099 (2014). https://doi.org/10.1007/s11665-014-1088-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1088-3