Abstract

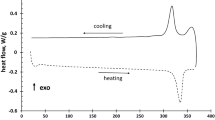

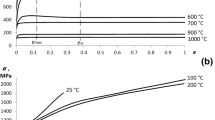

In this work, the ternary Ti-19.7Nb-5.8Ta (at.%) alloy for biomedical applications was studied. The ingot was manufactured by vacuum arc melting with a consumable electrode and then subjected to hot forging. Specimens were cut from the ingot and processed by cold rolling with e = 0.37 of logarithmic thickness reduction and post-deformation annealing (PDA) between 400 and 750 °C (1 h). Selected samples were subjected to aging at 300 °C (10 min to 3 h). The influence of the thermomechanical processing on the alloy’s structure, phase composition, and mechanical and functional properties was studied. It was shown that thermomechanical processing leads to the formation of a nanosubgrained structure (polygonized with subgrains below 100 nm) in the 500-600 °C PDA range, which transforms to a recrystallized structure of β-phase when PDA temperature increases. Simultaneously, the phase composition and the β → α″ transformation kinetics vary. It was found that after conventional cold rolling and PDA, Ti-Nb-Ta alloy manifests superelastic and shape memory behaviors. During aging at 300 °C (1 h), an important quantity of randomly scattered equiaxed ω-precipitates forms, which results in improved superelastic cyclic properties. On the other hand, aging at 300 °C (3 h) changes the ω-precipitates’ particle morphology from equiaxed to elongated and leads to their coarsening, which negatively affects the superelastic and shape memory functional properties of Ti-Nb-Ta alloy.

Similar content being viewed by others

References

I.J. Stevens, J. Alexander, Bone Implant, U.S. Patent 3579831, Issued 1971-05-25

G.C. Leventhal, Titanium: A Metal for Surgery, J. Bone Joint Surg., 1951, 33, p 473–474

C. Baker, The Shape-Memory Effect in a Titanium-35 wt.% Niobium Alloy, Met. Sci. J., 1971, 5, p 92–100

K. Takamura, K. Hayashi, N. Ishinishi, T. Yamasda, and Y. Sugioka, Evaluation of Carcinogenicity and Chronic Toxicity Associated with Orthopedic Implants in Mice, J. Biomed. Mater. Res., 1980, 28(5), p 583–589

M. Long and H.J. Rack, Titanium Alloys in Total Joint Replacement—A Material Science Perspective, Biomaterials, 1998, 19, p 1621–1639

M.I. Petrzhik, S.G. Fedotov, U.K. Kovneristiy, and N.F. Zhebyneva, Bлияниe тepмoциклиpoвaния нa cтpyктypy зaкaлeнныx cплaвoв cиcтeмы Ti-Ta-Nb (Influence of Thermocycling on the Structure of Quenched Ti-Ta-Nb Alloys), Met. Sci. Heat Treat. Met., 1992, 3, p 2–4 (in Russian)

S. Miyazaki, H.Y. Kim, and H. Hosoda, Development and Characterization of Ni-Free Ti-Base Shape Memory and Superelastic Alloys, Mater. Sci. Eng. A, 2006, 438-440, p 18–24

H.Y. Kim, Y. Ikehara, J.I. Kim, H. Hosoda, and S. Miyazaki, Martensitic Transformation, Shape Memory Effect and Superelasticity of Ti-Nb Binary Alloys, Acta Mater., 2006, 54(9), p 2419–2429

V. Brailovski, S. Prokoshkin, M. Gauthier, K. Inaekyan, S. Dubinskiy, M. Petrzhik, and M. Filonov, Bulk and Porous Metastable Beta Ti-Nb-Zr(Ta) Alloys for Biomedical Applications, Mater. Sci. Eng. C, 2011, 31, p 643–657

M. Geetha, A.K. Singh, A.K. Gogia, and R. Asokamani, Effect of Thermomechanical Processing on Evolution of Various Phases in Ti-Nb-Zr Alloys, J. Alloys Compd., 2004, 384, p 131–144

V. Brailovski, Stress-strain Diagrams, Chapter 6, Shape Memory Alloys: Fundamentals, Modeling and Applications, V. Brailovski, S. Prokoshkin, P. Terriault, and F. Trochu, Ed., ÉTS, Montréal, 2003, p 844

V. Brailovski, S. Prokoshkin, K. Inaekyan, S. Dubinskiy, and M. Gauthier, Mechanical Properties of Thermomechanically-Processed Metastable Beta Ti-Nb-Zr Alloys for Biomedical Applications, Mater. Sci. Forum, 2012, 706-709, p 455–460

E.W. Collings, The Physical Metallurgy of Titanium Alloys, ASM, Metals Park, 1984, p 223

K. Otsuka, C.M. Wayman, Mechanism of Shape Memory Effect and Superelasticity, Chapter 2, Shape Memory Materials, K. Otsuka, and C.M. Wayman, Ed., Cambridge University Press, 1998, p 284

S.M. Dubinskiy, S.D. Prokoshkin, V. Brailovski, A.V. Korotitskiy, K.E. Inaekyan, M.R. Filonov, and M.I. Petrzhik, Structure Formation During Thermomechanical Processing of Ti-Nb-Zr(Ta) Alloys and Manifestation of the Shape-Memory Effect, Phys. Met. Metall., 2011, 112, p 529–542

U. Krupp, Fatigue Crack Propagation in Metals and Alloys: Microstructural Aspects and Modeling Concepts, Wiley, New York, 2007, p 287

A. Kreitcberg, V. Brailovski, S. Prokoshkin, Y. Facchinello, K. Inaekyan, and S. Dubinskiy, Microstructure and Functional Fatigue of Nanostructured Ti-50.26at%Ni Alloy After Thermomechanical Treatment with Warm Rolling and Intermediate Annealing, Mater. Sci. Eng. A, 2013, 562, p 118–127

Acknowledgments

The present work was carried out with the financial support of the Natural Science and Engineering Research Council of Canada and of the Ministry of Education and Science of the Russian Federation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dubinskiy, S., Brailovski, V., Prokoshkin, S. et al. Structure and Properties of Ti-19.7Nb-5.8Ta Shape Memory Alloy Subjected to Thermomechanical Processing Including Aging. J. of Materi Eng and Perform 22, 2656–2664 (2013). https://doi.org/10.1007/s11665-013-0555-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-013-0555-6