Abstract

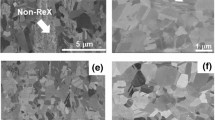

The intermediate temperature transition of the grain size effect on the yield strength of PM 3030 is investigated using compression tests from room temperature to 1200 °C. It is found that grain boundary strengthening is strong at low temperature which is consistent with conventional Hall–Petch hardening. However, the grain boundary contribution to strength diminishes exponentially at intermediate temperature and vanishes at the equicohesion point. Above the equicohesion point, finer grain structure leads to material softening primarily due to grain boundary diffusion and deformation processes. Maximum softening occurs at T soft-max which is about 70% of the melting point, then decreases logarithmically with further increase in temperature, and vanishes at the melting point. This can well be rationalized by the overwhelming dominance of volume diffusion over grain boundary diffusion at temperatures close to the melting point, which decreases the impact of grain size on material strength. An exponential transition from the Hall–Petch behavior to the diffusion-based behavior provides an overall better fit of test data as compared to a linear transition. This study provides a contribution to the understanding of equicohesion and variation of the grain size effect on material strength and can be particularly crucial for components used at intermediate temperature.

Similar content being viewed by others

References

E.O. Hall, The Deformation of Mild Steel: III Discussion of Results, Phys. Soc. B, 64, 1951, p 747–753

N.J. Petch, The Cleavage Strength of Polycrystals, J. Iron Steel Inst., 174, 1953, p 25–28

W.A. Counts, M.V. Braginsky, C.C. Battaile, E.A. Holm, Predicting the Hall-Petch Effect in FCC Metals Using Non-local Crystal Plasticity, Int. J. Plast., 24, 2008, p 1243–1263

R. Raj, M.F. Ashby, On the Grain Boundary Sliding and Diffusional Creep, Metall. Trans., 2, 1971, p 1113–1127

J.R. Spingarn, W.D. Nix, Diffusional Creep and Diffusionally Accommodated Grain Rearrangement, Acta Metall., 26, 1978, p 1389–1398

I.S. Servi and N.J. Grant, Creep and Stress Rupture Behavior of Aluminum as a Function of Purity, J. Metals, 1951, p 909–916

I.S. Servi and N.J. Grant, Structure Observations of Aluminum Deformed in Creep at Elevated Temperature, J. Metals, 1951, p 917–922

G.E. Dieter, Mechanical Metallurgy, SI Metric Editions, McGraw-Hill Book Company, London, 1986

R.L. Cairns, L.R. Curwick, J.S. Benjamin, Grain Growth in Dispersion Strengthened Superalloys by Moving Zone Heat Treatments, Metall. Trans. A, 6, 1975, p 179–188

J.S. Benjamin, Dispersion Strengthened Superalloys by Mechanical Alloying, Metall. Trans., 1, 1970, p 2943–2951

M. Nganbe, M. Heilmaier, High Temperature Strength and Failure of the Ni-base Superalloy PM 3030, Int. J. Plast., 25, 2009, p 822–837

B. deMestral, G. Eggeler, H.-J. Klam, On the Influence of Grain Morphology on the Creep Deformation and Damage Mechanisms in Directionally Solidified and Oxide Dispersion Strengthened Superalloys, Metall. Mater. Trans. A, 27, 1996, p 879–890

J.J. Stevens, W.D. Nix, The Effect of Grain Morphology on Longitudinal Creep Properties of INCONEL MA 754 at Elevated Temperature, Metall. Mater. Trans. A, 16, 1985, p 1307–1324

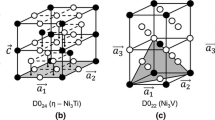

M. Nganbe, M. Heilmaier, Modelling of Particle Strengthening in the γ′ and Oxide Dispersion Strengthened Nickel-base Superalloy PM 3030, Mater. Sci. Eng. A, 387–389, 2004, p 609–612

R.F. Singer, R.C. Benn, and S.K. Kang, Creep Rupture Properties of Inconel Alloy MA 6000, Frontiers of High Temperature Materials, J.S. Benjamin and R.C. Benn, Ed., Inco Alloy Product Company, 1983, Vol. 2, p 336–357

H.J. Frost, M.F. Ashby, Deformation-Mechanism-Maps. The Plasticity and Creep of Metals and Ceramics, Pergamon Press, Oxford, 1982

U. Bayerlein, Zur Ermittlung der Textur- und Gefügeabhängigkeit der Elastischen Eigenschaften Sowie der Einkristallkonstanten von Superlegierungen bei Höheren Temperaturen (on the Determination of the Texture and Grain Structure Dependence of the Elastic Properties and Single Crystal Constants of Superalloys at High Temperatures), VDI Fortschrifttsberichte, 1991, 5(236), Düsseldorf (in German)

M. Nganbe, M. Heilmaier, L. Schultz, Dependence of Mechanical Strength on Grain Structure in the γ′ and Oxide Dispersion Strengthened Nickelbase Superalloy PM 3030, Z. Metallkunde 96(6), 2005, p 625–631

M. Mabuchi, K. Higashi, Strengthening Mechanisms of Mg-Si Alloys, Acta Mater., 44(11), 1996, p 4611–4618

M. Nganbe, “Untersuchung und Optimierung der γ′- und Oxiddispersionsgehärteten (ODS) Nickelbasissuperlegierung PM 3030 (Investigation and Optimization of the γ′- and Oxide Dispersion Strengthened (ODS) Nickel-base Superalloy PM 3030,” Dissertation thesis, Cuviller Verlag, Göttingen, 2002 (in German)

M. Heilmaier, M. Nganbe, and F.E.H. Müller, On the Creep and Superplastic Behavior of the ODS Nickel-based Superalloy PM 3030, Honorary Symposium for Professor Oleg D. Sherby, Deformation, Processing and Properties of Structural Materials, E.M. Taleff et al., Ed. (Warrendale, PA), TMS, 2000, p 287–298

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nganbe, M., Fahim, A. Equicohesion: Intermediate Temperature Transition of the Grain Size Effect in the Nickel-Base Superalloy PM 3030. J. of Materi Eng and Perform 19, 395–400 (2010). https://doi.org/10.1007/s11665-009-9512-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-009-9512-9