Abstract

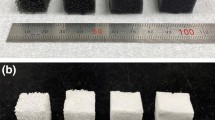

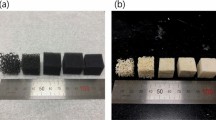

A multiphase reticulated porous ceramic (RPC) as Si3N4–Al2O3–SiO2 was fabricated by replication techniques. Proper volumes of additives and twice sinter- twice immerse process endow the RPC an excellent crack healing and submerging property. The compressive strength and fracture toughness improved owing to the crack bridging behavior. The existence of pores in struts in RPC blunt the crack tip and increased the external force needed to propagate the crack. The mechanisms play a beneficial role in enhancing the compressive strength and fracture strength. Si3N4 RPC with additives of 5%Al and 5% Al2O3 yielded the compressive strength of 9.8 MPa and fracture toughness of 0.3 MPa m1/2.

Similar content being viewed by others

References

R.W. Rice, Summary of porosity and micro-cracking applications, special fabrication, and engineering. Porosity of Ceramics, Chapter 10, Ed., Marcel Dekker, New York, 1998

Williams, E.J.A.E., Evans, J.R.G. (1996). Expanded Ceramic Foam. J. Mater. Sci. 31:559–563

Bhaduri, S.B. (1994). Science and Technology of Ceramic Foams. Adv. Performance Mater. 1:205–220

Sheppard, L.M. (1993). Porous Ceramics: Processing and Application. Ceram. Trans. 31:2–3

K. Schwartzwalder and A.V. Somers, Method of Making Porous Ceramic Articles, U.S. Patent 3090094, 1963

Saggio-Woyaansky, J., Scottetal, C.E. (1992). Processing of Porous Ceramics. Am. Ceram. Soc. Bull. 71(11):1674–1682

Taguchi, S.P., Ribeiro, S. (2004). Silicon Nitride Oxidation Behaviour at 1000 and 1200 ºC. J. Mater. Process. Technol. 147:336–342

Rosenflanz, A., (1999). Silicon Nitride and Sialon Ceramics. Curr. Opin. Solid State Mater. Sci. 4:453–459

Sancho, J.P., Pero-Sanz, J.A., Verdeja, L.F. (2003). Toughness of Si[3]N[4] Ceramics Obtained by Precipitating Sintering Aids as Hydroxides. Materials Character. 50:11–22

Chen, D.Y., Zhang, B.L., Zhang, H.R. (2003). Combustion Synthesis of Network Silicon Nitride Porous Ceramics. Ceram. Int. 29:363–364

Zhu, X., Jiang, D., Tan, S. (2002). The Control Of the Slurry Rheology in the Processing of Reticulated Ceramics. Mater. Res. Bull.. 37:541–553

Deng, Z.Y., Shi, J.L., Zhang, Y.F., Lai, T.R.,Guo, J.K. (1999). Creep and Creep Recovery Behavior on Silicon-Carbide-Particle-Reinforced Alumina. J. Am. Ceram. Soc. 82:944–952

Han, G.W., Feng, D., Yin, M. (1997). Ceramic/Aluminum Co-Continuous Composite Synthesized by Reaction Accelerated Melt Infiltration. Mater. Sci. Eng. A. 225(1–2):204–207

Natansohn, S., Pasto, A.E., Rourke, W.J. (1993). Effect of Powder Surface. Modifications on the Properties of Silicon Nitride Ceramics. J. Am. Ceram. Soc. 76(9):2273–2284

Gibson, L. J., Ashby, M. F. (1999). Cellular Solids, Structure and Properties 2nd ed. University Press,Cambridge

D.J. Green, Fabrication and Mechanical Properties of Lightweight Ceramics Produced by Sintering of Hollow Spheres, Final Report on AFOSR contract No.F49620-83-C0078, 1984

Green, D.J. (1983) J. Am. Ceram. Soc. 66:288–292

Maiti, K., Ashby, M.F., Gibson, L.J. (1984). Fracture Toughness of Brittle Cellular Solids. Scripta Metallurgica. 18:213–217

Deng, Z.Y., She, J., Inagaki, Y., Yang, J.F., Ohji, T., Tanaka, Y. (2004) Re-inforcement by Crack-Tip Blunting in Porous Ceramics. J. Eur. Ceram. Soc. 24:2055–2059

Awaji, H., Sakaida, Y. (1990). V-notch Technique for Single-Edge Notched Beam and Chevron Notch Methods. J. Am. Ceram. Soc. 73:3522–3523

Awaji, H., Choi, S. M., Jayaseelan, D.D. (2001). Indirect Estimation of Critical Frontal Process-Zone Size Using a Single-Edge V-Notched-Beam Technique. J. Ceram. Soc. Japan 109:591–595

Acknowledgments

This work was supported by the Natural Science Foundation of Shandong province (Y2006F03). Part of this research was done at the Institute of Materials Science and Technology of Jinan University. The authors are owing a debt of gratitude to the technical staff of these two institutions for their help.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Sr., Geng, Hr., Hui, Lh. et al. Reticulated Porous Multiphase Ceramics with Improved Compressive Strength and Fracture Toughness. J of Materi Eng and Perform 16, 113–118 (2007). https://doi.org/10.1007/s11665-006-9018-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-006-9018-7