Abstract

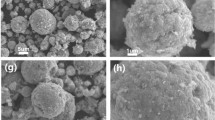

The interfacial structure between the inorganic filler and epoxy resin matrix in epoxy resin (EP) composites has a great influence on the mechanical properties, thermal conductivity, and electrical properties. In this paper, two micro@nanostructured Al2O3 fillers and their epoxy resin composites were prepared, and their morphology, interfacial bond strength, mechanical properties, thermal conductivity, and electrical properties systematically tested and analyzed. The experimental results show that modification by a nano-Al2O3 coating on the surface of micro-Al2O3 can effectively improve the infiltration of Al2O3 filler and epoxy resin, reduce the interfacial defects caused by weak bonding of Al2O3 filler and epoxy resin, and thus synergistically improve the mechanical properties, thermal conductivity, and electrical properties of epoxy resin composites. The thermal conductivity was improved by 22.5% compared with 22.65% when using micro-Al2O3/EP, the tensile and flexural strength were improved by 36.67% and 20.82%, and the alternating-current breakdown strength was improved by 12.88%. In addition, thermally stimulated current experiments were carried out to study the electron transport properties of micro@nano-Al2O3 epoxy resin composites, revealing that filler nanomodification could improve the trap depth, suppress the carrier transport, and improve the dielectric properties of the composites.

Graphic Abstract

Similar content being viewed by others

References

A. Agrawal, and A. Satapathy, Thermal and dielectric behavior of epoxy composites filled with ceramic micro particulates. J. Compos. Mater. 48, 3755 (2014).

S.H. Tzeng, and J.L. Tsai, Size effect on fracture behaviours of epoxy composites with micron and nano alumina particles. Key Eng. Mater. 334–335, 777 (2007).

P. Nisha, K.I. Dhanalekshmi, and C. Ravichandran, Effect of 4-aminobutyltriethoxysilane modified Al2O3 nanoparticles on the dielectric properties of epoxy nanocomposites for high voltage applications. SILICON 13, 1009 (2021).

J.T. Lewis, Nanometric dielectrics. Dielectrics and Electrical Insulation IEEE Transactions on 1, 812 (1994)

J. Yu, R. Huo, C. Wu, X. Wu, G. Wang, and P. Jiang, Influence of interface structure on dielectric properties of epoxy/alumina nanocomposites. Macromol. Res. 20, 816 (2012).

N.H. Rahim, K.Y. Lau, N.A. Muhamad, N. Mohamad, W.A.W.A. Rahman, and A.S. Vaughan, Effects of filler calcination on structure and dielectric properties of polyethylene/silica nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 26, 284 (2019).

R. Mi, Z. Xing, J. Hao, X. Hu, D. Min, S. Li, and Q. Wu, Effect of morphology and traps on DC conductivity and breakdown of polyethylene nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 27, 489 (2020).

J.D. Kim, J. Zhu, H. Peng, J.L. Margrave, V.N. Khabashesku, and E.V. Barrera, Improving the dispersion and integration of single-walled carbon nanotubes in epoxy composites through functionalization. Nano Lett. 3, 1107 (2003).

S. Li, S. Yu, and Y. Feng, Progress in and prospects for electrical insulating materials. High Voltage 1, 122 (2016).

J. Li, Y. Ye, J. Li, and Y. Ye, Densification and grain growth of Al2O3 nanoceramics during pressureless sintering. J. Am. Ceram. Soc. 89, 139 (2010).

A. Heiman, E. Lakin, E. Zolotoy Ab Ko, A. Hoffman, Microstructure and stress in nano-crystalline diamond films deposited by DC glow discharge CVD. Diamond Relat. Mater. 11, 601 (2002).

G.O. Berim, and E. Ruckenstein, Nanodrop on a nanorough hydrophilic solid surface: contact angle dependence on the size, arrangement, and composition of the pillars. J. Colloid Interface Sci. 359, 304 (2011).

P. Adamson, Ellipsometry of anisotropic (sub)nanometric dielectric films on absorbing materials. J. Mod. Opt. 61, 424 (2014).

S. Zhang, X.Y. Cao, Y.M. Ma, Y.C. Ke, J.K. Zhang, and F.S. Wang, The effects of particle size and content on the thermal conductivity and mechanical properties of Al2O3/high density polyethylene (HDPE) composites. Express Polym. Lett. 5, 581 (2011).

W. Karnthidaporn, Hathaikarn, Manuspiya, Nantaya, Yanumet, effective surface treatments for enhancing the thermal conductivity of BN-filled epoxy composite. J. Appl. Polym. Sci. 119, 3234 (2010).

M.Z. Khan, F. Wang, L. He, Z. Shen, and M.A. Mehmood, Influence of treated nano-alumina and gas-phase fluorination on the dielectric properties of epoxy resin/alumina nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 27, 410 (2020).

S.S. Vaisakh, M. Hassanzadeh, R. Metz, S. Ramakrishnan, D. Chappelle, J.D. Sudha, and S. Ananthakumar, Effect of nano/micro-mixed ceramic fillers on the dielectric and thermal properties of epoxy polymer composites. Polym. Adv. Technol. 25, 240 (2014).

Y. Chen, D. Zhang, X. Wu, H. Wang, Y. Xue, R. Wu, Z. Zhang, and Y. Chen, Epoxy/α-alumina nanocomposite with decreased dielectric constant and dielectric loss. Polym. Compos. 39, 2307 (2018).

M.Z. Khan, F. Wang, L. He, Z. Shen, Z. Huang, and M.A. Mehmood, Influence of treated nano-alumina and gas-phase fluorination on the dielectric properties of epoxy resin/alumina nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 27, 410 (2020).

H. Yang, Q. Chen, X. Wang, M. Chi, H. Liu, X. Dielectric and Thermal Conductivity of Epoxy Resin Impregnated Nano-h-BN Modified Insulating Paper Ning. Polymers 11 (2019).

H. Li, L. Li, L. Li, W. Wang, X. Huang, Q. Chen, and F. Lin, Study on the impact of space charge on the lifetime of pulsed capacitors. IEEE Trans. Dielectr. Electr. Insul. 24, 1870 (2017).

T. Tanaka, Dielectric nanocomposites with insulating properties. IEEE Trans. Dielectr. Electr. Insul. 12, 914 (2005).

J.A. Anta, G. Marcelli, M. Meunier, and N. Quirke, Models of electron trapping and transport in polyethylene: current-voltage characteristics. J. Appl. Physiol. 92, 1002 (2002).

P. Pfluger, H.R. Zeller, and J. Bernasconi, Hot-electron transport in polymeric dielectrics. Phys. Rev. Lett. 53, 94 (1984).

Acknowledgments

This work was supported by Science and Technology Project of SGCC (52094020006W).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mai, Y., Du, B., Liu, Q. et al. Influence of Micro@Nano-Al2O3 Structure on Mechanical Properties, Thermal Conductivity, and Electrical Properties of Epoxy Resin Composites. J. Electron. Mater. 51, 232–242 (2022). https://doi.org/10.1007/s11664-021-09283-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-021-09283-y