Abstract

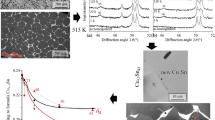

Cu6(Sn, In)5 phase intermetallic compounds (IMCs) were generated by In doping in Sn-Ag-Cu(SAC) solders. First, the optimum site of the In atom replacing the Sn atom was determined. Subsequently, the elastic constants of the IMCs were calculated based on the determined structure. All calculations were performed using first-principles calculations. The results show that Cu24Sn19In1 is a new IMC, and its structural stability is better than that of Cu6Sn5. Moreover, the anisotropy of Cu24Sn19In1 is stronger than that of Cu6Sn5. Based on first-principles calculations and VRH methods, the bulk modulus, shear modulus, Young’s modulus, and Poisson's ratio of polycrystalline Cu6Sn5 are 78.31 GPa, 39.00 GPa, 100.35 GPa, and 0.2864 GPa, respectively, and 88.08 GPa, 41.42 GPa, 107.43 GPa, and 0.2967 GPa of Cu24Sn19In1, respectively. All elastic moduli of the latter are larger than those of the former. The formation of a Cu24Sn19In1 IMC can improve the mechanical properties of the IMC layer.

Similar content being viewed by others

References

M. Zhao, L. Zhang, Z.Q. Liu, M.Y. Xiong, and L. Sun, Sci. Technol. Adv. Mater. 20, 421 (2019).

M.Y. Xiong, and L. Zhang, J. Mater. Sci. 54, 1741 (2018).

A.K. Gain, Y.C. Chan, and W.K.C. Yung, Microelectron. Reliab. 51, 975 (2011).

A.S.M.A. Haseeb, M.M. Arafat, and M.R. Johan, Mater. Charact. 64, 27 (2012).

J.F. Li, P.A. Agyakwa, and C.M. Johnson, J. Alloy. Compd. 545, 70 (2012).

N. Dariavach, P. Callahan, J. Liang, and R. Fournelle, J. Electron. Mater. 35, 1581 (2006).

F.J. Cheng, F. Gao, H. Nishikawa, and T. Takemoto, J. Alloy. Compd. 472, 530 (2009).

V.M.F. Marques, C. Johnston, and P.S. Grant, Acta Mater. 61, 2460 (2013).

W.B. Zhu, W.W. Zhang, W. Zhou, and P. Wu, J. Alloy. Compd. 789, 805 (2019).

J. Wu, S.B. Xue, J.W. Wang, J.X. Wang, and D. Yangbao, J. Mater. Sci. Mater. Electron. 29, 19663 (2018).

V. Jayaram, S. McCann, B. Singh, R. Pulugurtha, V. Smet, R. Tummala, H. Matsuura, and Y. Takagi, in: 67th Electronic Components and Technology Conference (ECTC) (2017), pp. 1405–1412.

S. Tian, S.P. Li, J. Zhou, and F. Xue, J. Alloy. Compd. 742, 835 (2018).

M. Qu, T.Z. Cao, Y. Cui, F.B. Liu, Z.W. Jiao, and C. Li, in: IOP Conference Series: Materials Science and Engineering, (2018).

K. Kanlayasiri, M. Mongkolwongrojn, and T. Ariga, J. Alloy. Compd. 485, 225 (2009).

J.X. Wang, M. Yin, Z.M. Lai, and X. Li, Trans. China Weld. Inst. 32, 69 (2011).

S. Chantaramanee, P. Sungkhaphaitoon, and T. Plookphol, Solid State Phenom. 266, 196 (2017).

K.S. Kim, S.H. Huh, and K. Suganuma, J. Alloy. Compd. 352, 226 (2003).

A. Sharif, and Y.C. Chan, J. Alloy. Compd. 390, 67 (2005).

P. Šebo, Z. Moser, P. Švec, D. Janičkovič, E. Dobročka, W. Gasior, and J. Pstruś, J. Alloy. Compd. 480, 409 (2009).

N.T.S. Lee, V.B.C. Tan, and K.M. Lim, Appl. Phys. Lett. 88, 031913 (2006).

W.W. Zhang, Y. Ma, W. Zhou, and P. Wu, J. Electron. Mater. 48, 4533 (2019).

X.Y. Bi, X.W. Hu, X.X. Jiang, and Q.L. Li, Vacuum 164, 7 (2019).

M.D. Segall, P.J.D. Lindan, M.J. Probert, C.J. Pickard, P.J. Hasnip, S.J. Clark, and M.C. Payne, J. Phys.-Condes. Matter. 14, 2717 (2002).

J.P. Perdew, K. Burke, and M. Ernzerhof, Phys. Rev. Lett. 77, 4 (1996).

A. Jain, S.P. Ong, G. Hautier, W. Chen, W.D. Richards, S. Dacek, S. Cholia, D. Gunter, D. Skinner, G. Ceder, and K.A. Persson, Apl. Mater. 1, 011002 (2013).

R. Hill, Proc. Phys. Soc. A. 65, 349 (1952).

G. Ghosh, and M. Asta, J. Mater. Res 20, 3102 (2005).

Z. Chen, C. Liu, B. An, Y. Wu, and L. Liu, J. Mater. Sci. Mater. Electron. 28, 17461 (2017).

S.F. Pugh, Philos. Mag. 45, 823 (1954).

M.T. Zarmai, and C.F. Oduoza, Microelectron. Reliab. 116, 114008 (2021).

A.A. El-Daly, and A.E. Hammad, J. Alloy. Compd. 509, 8554 (2011).

Acknowledgments

The authors would like to acknowledge the generous support from the National Natural Science Foundation of China (NSFC 61474032) and National Defense Basic Scientific Research Program of China under Grant JSZL2018204B003. The authors also would like to thank Editage (www.editage.cn) for English language editing.

Funding

This study was sponsored by the National Natural Science Foundation of China (NSFC 61474032) and the National Defense Basic Scientific Research Program of China under Grant (JSZL2018204B003).

Author information

Authors and Affiliations

Contributions

WH performed the simulation, analyzed the data, and wrote the draft; KP guided the simulation and provided the funding; JZ edited the paper; YG reviewed the paper and provided the funding.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Huang, W., Pan, K., Zhang, J. et al. Effect of In-Doping on Mechanical Properties of Cu6Sn5-Based Intermetallic Compounds: A First-Principles Study. J. Electron. Mater. 50, 4164–4171 (2021). https://doi.org/10.1007/s11664-021-08929-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-021-08929-1