Abstract

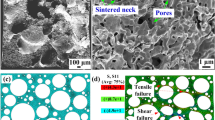

Characterizations of equivalent thermal conductivity (ETC) of sintered silver is an important topic due to the thermal–mechanical reliability requirements of electronic packaging. In this paper, the effect of various types of cracks on the ETC of sintered silver are discussed. A numerical method to simulate the heat transfer behaviors of porous sintered silver containing the crack effect is presented. The results show that the ETC of sintered silver depends significantly on the crack length, crack orientation, porosity, and pore shape. Theoretical formulae to estimate the ETC of sintered silver are also presented, in which the effects of arbitrary crack depth, arbitrary crack orientation, arbitrary porosity, and arbitrary pore shape factor on ETC are included. It has been found that the influence of the side edge crack on the reduction of the ETC of sintered silver is the most obvious compared with the center crack and the upper edge crack. This study presents a quantitative method to evaluate the crack effect on the ETC of porous sintered silver.

Similar content being viewed by others

References

C. Chen, S. Nagao, H. Zhang, J. Jiu, T. Sugahara, K. Suganuma, and K. Tsuruta, J. Electron. Mater. 46, 1576 (2017).

Y.H. Mei, G. Chen, X. Li, G.Q. Lu, and X. Chen, Solder Surf. Mt Tech. 25, 107 (2013).

K.S. Siow, J. Electron. Mater. 43, 947 (2014).

Y. H. Mei, Z. Wang, K.S. Siow, in Die-Attach Materials for High Temperature Applications in Microelectronics Packaging, ed. by Siow and Kim Shyong (Springer, Cham, 2019), p. 125–150.

R. Kimura, Y. Kariya, N. Mizumura and K. Sasaki, Mater Trans, M2017392 (2018).

Y. Tan, X. Li, G. Chen, Y.H. Mei, and X. Chen, J. Electron. Mater. 44, 761 (2015).

R. Shioda, Y. Kariya, N. Mizumura, and K. Sasaki, J. Electron. Mater. 46, 1155 (2017).

P. Agyakwa, J. Dai, J. Li, B. Mouawad, L. Yang, M. Corfield, and C.M. Johnson J Microsc-Oxford. 0(0), 1 (2019).

J. Dai, J. Li, P. Agyakwa, M. Corfield, and C.M. Johnson, IEEE T Device Mater. Reliab. 18, 256 (2018).

T. Herboth, M. Guenther, A. Fix, and J. Wilde in 2013 IEEE 63rd Electronic Components and Technology Conference, 1621 (2013).

C. Chen, S. Nagao, K. Suganuma, J. Jiu, T. Sugahara, H. Zhang, and K. Tsuruta, Acta Mater. 129, 41 (2017).

S. Sakamoto, T. Sugahara, and K. Suganuma, J. Maters. Sci. Mater. Electron. 24, 1332 (2013).

J. Carr, X. Milhet, P. Gadaud, S.A. Boyer, G.E. Thompson, and P. Lee, J. Mater. Process Technol. 225, 19 (2015).

T. Youssef, W. Rmili, E. Woirgard, S. Azzopardi, N. Vivet, D. Martineau, and C. Richard, Microelectron. Reliab. 55, 1997 (2015).

J. Ordonez-Miranda, M. Hermens, I. Nikitin, V.G. Kouznetsova, O. van der Sluis, M.A. Ras, and C.S. Torres, Int. J. Therm. Sci. 108, 185 (2016).

F. Qin, Y.K. Hu, Y.W. Dai, T. An, and P. Chen, Microelectron. Reliab. 108, 113633 (2020).

S.A. Paknejad and S.H. Mannan, Microelectron. Reliab. 70, 1 (2017).

K.S. Siow and S.T. Chua, Met. Mater. Int. (2019). https://doi.org/10.1007/s12540-019-00394-0.

X. Long, B. Hu, Y. Feng, C. Chang, and M. Li, Int. J. Mech. Sci. 161, 105020 (2019).

P. Gadaud, V. Caccuri, D. Bertheau, J. Carr, and X. Milhet, Mater. Sci. Eng. A 669, 379 (2016).

I. Sumirat, Y. Ando, and S. Shimamura, J. Porous. Mater. 13, 439 (2006).

A. El Moumen, T. Kanit, A. Imad, and H. El Minor, Comp. Mater. Sci. 97, 148 (2015).

H.S. Carslaw and J.C. Jaeger, 2nd Edition. (Clarendon, Oxford, 1959), pp. 1–84.

A.A. Wereszczak, D.J. Vuono, H. Wang, M.K. Ferber, and Z. Liang, Properties of Bulk Sintered Silver as a Function of Porosity (No. ORNL/TM-2012/130), Oak Ridge National Lab. (ORNL), Oak Ridge, TN, USA, (2012).

N. Heuck, A. Langer, A. Stranz, G. Palm, R. Sittig, A. Bakin, and A. Waag, IEEE Trans. Compon. Pack Manuf. 1, 1846 (2011).

W. Kaddouri, A.E. Moumen, T. Kanit, S. Madani, and A. Imad, Mech. Mater. 92, 41 (2016).

Acknowledgments

The authors acknowledge the support from the National Natural Science Foundation of China (11902009 and 11672009), the Beijing Natural Science Foundation (2204074), the Scientific Research Common Program of Beijing Municipal Commission of Education (KM202010005034), the China Postdoctoral Science Foundation (2019M650403) and the Chaoyang District Postdoctoral Science Foundation (2019ZZ-47).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Qin, F., Hu, Y., Dai, Y. et al. Crack Effect on the Equivalent Thermal Conductivity of Porously Sintered Silver. J. Electron. Mater. 49, 5994–6008 (2020). https://doi.org/10.1007/s11664-020-08325-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-020-08325-1