Abstract

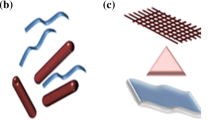

An electrochemical discharge machining process to produce zinc oxide (ZnO) nanoparticles (NPs) under varying voltage and duty factors has been investigated. The morphological and optical characterizations of the generated ZnO NPs were carried out. It was observed that the production rate of NPs and their size increased with an increase in voltage. The ZnO NPs produced at 120 V showed the maximum production rate larger NPs. The field-effect scanning electron microscope images of the NPs revealed a nanorod-like structure, large conical shape rods and hexagonal wurtzite-like structures. The ZnO NPs generated at 120 V and 20% duty factor presented less agglomeration of NPs compared to other NPs generated by varying electrical parameters. The crystal size of the ZnO NPs were found to vary from 31.08 nm to 50.37 nm. The ZnO NPs were also tested for use in a supercapacitor electrode, and the results showed that the specific capacitance of the electrode was 708.75 F/g at a current density of 1 A/g and a retained capacity of 90.42%.

Similar content being viewed by others

References

S. Arya, P.K. Lehana, and B.S. Rana, J. Electron. Mater. 46, 4604 (2017).

A.K. Radzimska and T. Jesionowski, Materials 7, 2833 (2014).

S. Singhal, J. Kaur, T. Namgyal, and R. Sharma, Phys. B Condens. Matter 407, 1223 (2012).

M. Arakha, R. Jyoti, N.S. Parth, M. Bibekanand, and J. Suman, Free Radic. Biol. Med. 42, 110 (2017).

J. Song, J. Bian, E. Zheng, X. Wang, W. Tian, and T. Miyasaka, Chem. Lett. 44, 610 (2015).

J.L. Yang, S.J. An, W. Il Park, G.C. Yi, and W. Choi, Adv. Mater. 16, 1661 (2004).

C. Wang, L. Yin, L. Zhang, D. Xiang, and R. Gao, Sensors 10, 2088 (2010).

A. Tereshchenkoa, M. Bechelany, R. Viter, V. Khranovskyy, V. Smyntyna, N. Starodub, and R. Yakimova, Sens. Actuat. B. Chem. 229, 664 (2016).

K. Zeng, J. Li, Z. Zhang, M. Yan, Y. Liao, X. Zhang, and C. Zhao, J. Mater. Chem. B 3, 5249 (2015).

J.X. Wang, X.W. Sun, A. Wei, Y. Lei, X.P. Cai, C.M. Li, and Z.L. Dong, Appl. Phys. Lett. 88, 233106 (2006).

S. Abdi and D. Dorranian, Opt. Laser Technol. 108, 372 (2018).

V.S. Burakov, N.A. Savastenko, N.V. Tarasenko, and E.A. Nevar, J. Appl. Spectrosc. 75, 114 (2008).

D. Ramimoghadam, S. Bagheri, and S.B.A. Hamid, J. Magn. Magn. Mater. 368, 207 (2014).

O.A. Yildirim and C. Durucan, J. Alloys Compd. 506, 944 (2010).

M. Guo, P. Diao, and S. Cai, Appl. Surf. Sci. 249, 71 (2005).

L. Li, S. Pu, Y. Liu, L. Zhao, J. Ma, and J. Li, Adv. Powder Technol. 29, 2194 (2018).

M.M. Ba-Abbad, A.A.H. Kadhum, A.B. Mohamad, M.S. Takriff, and K. Sopian, J. Alloys. Compd. 550, 63 (2013).

K. Minegishi, Y. Koiwai, Y. Kikuchi, K. Yano, M. Kasuga, and A. Shimizu, Jpn. J. Appl. Phys., Part 2 Lett. 36, 1453 (1997).

A.J. Cheng, Y. Tzeng, Y. Zhou, M. Park, T.H. Wu, C. Shannon, D. Wang, and W. Lee, Appl. Phys. Lett. 92, 92113 (2008).

P.K. Singh, H. Bishwakarma, Shubham, and A.K. Das, J. Electron. Mater. 46, 5715 (2017).

Y. Liu, X. Li, Y. Li, Z. Zhao, and F. Bai, Appl. Phys. A: Mater. Sci. Process. 122, 174 (2016).

A. Ziashahabi, R. Poursalehi, and N. Naseri, Adv. Powder Technol. 29, 1246 (2018).

C.J. Li, X. Cao, W.H. Li, B.W. Zhang, L.Q. Xiao, X. Cao, W.H. Li, B.W. Zhang, and L.Q. Xiao, J. Alloys. Compd. 773, 762 (2018).

R.N. Yadav, Proc. Inst. Mech. Eng. Part B: J. Eng. Manuf. 233, 1037 (2019).

N. Sabahi, M.R. Razfar, and M. Hajian, J. Mater. Process. Technol. 250, 190 (2017).

S.S. Kumar, P. Venkateswarlu, V.R. Rao, and G.N. Rao, Int. Nano Lett. 1, 30 (2013).

H.Y. Lu, S.Y. Chu, and S.S. Tan, J. Cryst. Growth 269, 385 (2004).

H. Sarma and K.C. Sarma, Int. J. Sci. Res. Publ. 4, 1 (2014).

P.K. Gupta, J.P. Bhamu, C.S. Rajoria, N.K. Lautre, and V. Agarwal, in MATEC Web Conf. vol 77 (2016).

B. Jiang, S. Lan, K. Wilt, and J. Ni, Int. J. Mach. Tool. Manuf. 90, 8 (2015).

C.P. Cheng, K.L. Wu, C.C. Mai, C.K. Yang, Y.S. Hsu, and B.H. Yan, Int. J. Mach. Tools Manuf. 50, 689 (2010).

A. Sarić, S. Goran, D. Goran, and G. Marijan, J. Alloys Compd. 652, 99 (2015).

R. Shama, A. Mumtaz, and S.K. Hasanain, J. Nanoparticle Res. 6, 2497 (2011).

S. Phoka, P. Laokul, E. Swatsitang, V. Promarak, S. Seraphin, and S. Maensiri, Mater. Chem. Phys. 115, 423 (2009).

L.C. Nehru and C. Sanjeeviraja, J. Adv. Ceram. 3, 171 (2014).

M.M. Hassan, W. Khan, A. Azam, and A.H. Naqvi, J. Lumin. 145, 160 (2014).

M.J. Chithra, M. Sathya, and K. Pushpanathan, Acta Metall. Sin.-Engl. 28, 394 (2015).

A. De Adhikari, R. Oraon, S.K. Tiwari, N.K. Jena, J.H. Lee, N.H. Kim, and G.C. Nayak, Chem.—Asian J. 12, 900 (2017).

P.K. Singh, A.K. Das, G. Hatui, and G.C. Nayak, Mater. Chem. Phys. 198, 16 (2017).

R.S. Ray, B. Sarma, and M. Misra, Mater. Lett. 155, 102 (2015).

X.Y. Liu, H. Chen, G. Li, J.H. Peng, and Y.X. Zhang, Ceram. Int. 42, 9227 (2016).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bishwakarma, H., Das, A.K. Synthesis of Zinc Oxide Nanoparticles Through Hybrid Machining Process and Their Application in Supercapacitors. J. Electron. Mater. 49, 1541–1549 (2020). https://doi.org/10.1007/s11664-019-07835-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-019-07835-x