Abstract

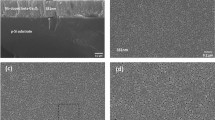

This paper investigates the optimized sputtering conditions for high quality gallium oxide (Ga2O3) thin films while maintaining a strong uniformity within a specific surface area. The research also analyzes the crystal structure and the morphology of gallium oxide (Ga2O3) thin films. We report a comprehensive investigation of two different types of Ga2O3 synthetization processes: (1) direct deposition using radio frequency (RF) magnetron sputter technique and (2) thermal oxidation of gallium nitride (GaN) samples. A detailed comparison is presented in terms of material characterization, surface analysis and electrical performance for each of the synthetization processes. X-ray photoelectron spectroscopy, scanning electron microscopy, atomic force microscopy and x-ray diffraction (XRD) are employed to study the gallium oxide (Ga2O3) epi-layers on each of the samples. Based on the analysis, Ga2O3 compound is found on all samples with a binding energy ranging from 21 eV to 21.38 eV. Depending on the synthetization process, the thickness varied from 20 nm to 100 nm for RF sputtering process and a maximum of ~ 400 nm for thermal oxidation method. Additionally, the observations revealed that Ga2O3 is formed on the surface, as well as inside the gallium nitride (GaN) film after thermal oxidation. Crystal features are observed on the surface of each of the samples after annealing treatment while XRD analysis showed the presence of the beta (β) polymorph for the annealed samples. After thorough characterization, radio frequency sputtering technique proved to be superior due to its higher purity level and ability to create polycrystalline structures by adding temperature during deposition.

Similar content being viewed by others

References

R.F. Pierret, Semiconductor Device Fundamentals (Boston: Addison-Wesley Publishing Company, 1996).

F. Roccaforte, F. Giannazzo, F. Lucolano, J. Eriksson, M.H. Weng, and V. Raineri, Appl. Surf. Sci. 256, 5727 (2010).

H.S. Oon and K.Y. Cheong, Mater. Sci. Semicond. Process. 16, 1217 (2013).

B.G. Svensson, S.J. Pearton, and C. Jagadish, Semicond Semimet 88, 2 (2013).

R.G. Gordon, Mater. Res. Soc. 25, 52 (2000).

P. Irvin, Y. Ma, D.F. Bogorin, C. Cen, C.W. Bark, C.M. Folkman, C.-B. Eom, and J. Levy, Nat. Photonics 4, 849 (2010).

K. Nomura, H. Ohta, K. Ueda, T. Kamiya, M. Hirano, and H. Hosono, Science 300, 5623 (2003).

M. Higashiwaki, K. Sasaki, A. Kuramata, T. Masui, and S. Yamakoshi, Phys. Status Solidi A 211, 21 (2014).

S.-A. Lee, J.-Y. Hwang, J.-P. Kim, S.-Y. Jeong, and C.-R. Cho, Appl. Phys. Lett. 89, 182906 (2006).

D.J. Fu, Y.H. Kwon, T.W. Kang, C.J. Park, K.H. Baek, H.Y. Cho, D.H. Shin, C.H. Lee, and K.S. Chung, Appl. Phys. Lett. 80, 446 (2002).

X.-C. Wang, G.-C. Lim, H.-Y. Zheng, J.-L. Tan, W. Liu, and S.-J. Chua, Jpn. J. Appl. Phys. 42, 5638 (2003).

Y. Kokubun, T. Abe, and S. Nakagomi, Phys. Status Solidi A 207, 1741 (2010).

G.A. Battiston, R. Gerbasi, M. Porchia, R. Bertoncello, and F. Caccavale, Thin Solid Films 279, 115 (1996).

R. Roy, V.G. Hill, and E.F. Osborn, J. Am. Chem. Soc. 74, 719 (1952).

L. Li, W. Wei, and M. Behrens, Solid State Sci. 14, 971 (2012).

S.I. Stepanov, V.I. Nikolaev, V.E. Bougrov, and A.E. Romanov, Rev. Adv. Mater. Sci. 44, 63 (2016).

S.-D. Lee, K. Akaiwa, and S. Fujita, Phys. Status Solidi 10, 1592 (2013).

Y. Zhou, C. Ahyi, T. Isaacs, M. Bozack, C.C. Tin, J. Williams, M. Park, A. Cheng, J.H. Park, D.J. Kim, D. Wang, E.A. Preble, A. Hanser, and K. Evans, Solid State Electron. 52, 756 (2008).

H.S. Oon and K.Y. Cheong, Mater. Chem. Phys. 137, 381 (2012).

H.-D. Xiao, H.-L. Ma, C.-S. Xue, H.-Z. Zhuang, J. Ma, F.-J. Zong, and X.-J. Zhang, Mater. Chem. Phys. 101, 99 (2007).

C.D. Wagner, D.A. Zatko, and R.H. Raymond, Anal. Chem. 52, 1445 (1980).

H. Iwakuro, C. Tatsuyama, and S. Ichimura, Jpn. J. Appl. Phys. 21, 94 (1982).

A. Pashutski and M. Folman, Surf. Sci. 216, 395 (1989).

H.J. Lee, S.M. Kang, T.I. Shin, J.W. Shur, and D.H. Yoon, J. Ceram. Process. Res. 9, 180 (2008).

R. Carli and C.L. Bianchi, Appl. Surf. Sci. 74, 99 (1994).

A. Navarro-Quezada, Z. Galazka, S. Alame, and N. Esser, Appl. Surf. Sci. 349, 368 (2015).

Acknowledgments

The authors gratefully acknowledge the support received from National Science Foundation under PREM Grant No. DMR-1523577 ‘‘UTRGV-UMN Partnership for Fostering Innovation by Bringing Excellence in Research and Student Success’’. Also, to the UTRGV student and faculty Edgar Muñoz and Hilario Cortes for their technical assistant on XPS and SEM characterization. This project is supported in part by the National Science Foundation (NSF) under Grant No. 1229523, and by the US Army Research Office W911NF-14-1-0100.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Castillo, J., Garcia-Perez, R. & Huq, H. Optimized Growth of Gallium Oxide Thin Films Using Different Synthesis Processes. J. Electron. Mater. 48, 536–541 (2019). https://doi.org/10.1007/s11664-018-6746-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-018-6746-z