Abstract

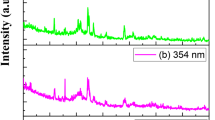

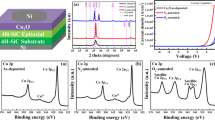

A process for fabrication of kesterite-based Cu2ZnSnS4 (CZTS) thin films from metal-thiourea precursor solution by dip coating is described. As deposited CZTS films were sulphurized at different temperatures to study the effects of sulphurization temperature on structural, optical and electrical properties. Formation of tetragonal CZTS phase was confirmed by x-ray diffraction; phase purity of the films was further studied by Raman spectroscopy. The studies revealed phase pure crystal structure for the films sulphurized at 500°C and 550°C. Larger crystallite size was observed for films sulphurized at 550°C. Scanning electron microscopy studies showed uniform distribution of particles in the film sulphurized at 550°C, and the determined thickness of the films was ∼ 2 μm. Energy dispersive x-ray spectroscopy analysis revealed the effect of sulphurization temperature on elemental compositions of the films. Optical studies suggest that CZTS thin film sulphurized at 550°C has high absorption coefficient (105 cm−1) with an optical energy band gap of 1.43 eV. P-type nature of the films was confirmed from Hall Effect analysis. Carrier concentration, mobility and resistivity of the films sulphurized at 550°C were also calculated. The study optimized fabrication conditions for device quality CZTS thin films from metal-thiourea precursor solution by simple dip coating.

Similar content being viewed by others

References

X. Zeng, K.F. Tai, T. Zhang, C.W. Ho, X. Chen, A. Huan, T. Sum, and L.H. Wong, Sol. Energy Mater. Sol. Cells 124, 55 (2014).

H. Yoo and J. Kim, Sol. Energy Mater. Sol. Cells. 95, 239 (2011).

T.K. Todorov, K.B. Reuter, and D.B. Mitzi, Adv. Mater. 25, 22 (2010).

K. Tanaka, N. Moritake, M. Oonuki, and H. Uchiki, Jpn. J. Appl. Phys. 47, 598 (2008).

P. Prabeesh, I.P. Selvam, and S.N. Potty, Thin Solid Films 606, 94 (2016).

Y. Sun, K. Zong, H. Zheng, H. Wang, J. Liu, H. Yan, and M. Zhu, Mater. Lett. 92, 195 (2013).

J. Ge, J. Chu, J. Jiang, Y. Yan, and P. Yang, ACS Sustain. Chem. Eng. 3, 3043 (2015).

P. Prabeesh, P. Saritha, I.P. Selvam, and S.N. Potty, Mater. Res. Bull. 86, 295 (2017).

S. Siebentritt, Thin Solid Films 535, 1 (2013).

K. Patel, V. Kheraj, D.V. Shah, C.J. Panchal, and N.G. Dhere, J. Alloys Compd. 663, 842 (2016).

D. Dumcenco and Y.S. Huang, Opt. Mater. 35, 419 (2013).

A. Khare, B. Himmetoglu, M. Johnson, D.J. Norris, M. Cococcioni, and E.S. Aydil, J. Appl. Phys. 111, 083707 (2012).

S. Kermadi, S. Sali, F.A. Ameur, L. Zougar, M. Boumaour, A. Toumiat, N.N. Melnik, D.W. Hewak, and A. Duta, Mater. Chem. Phys. 169, 96 (2016).

P.A. Fernandes, P.M. Salomé, and A.F. Cunha, J. Alloys Compd. 509, 7600 (2011).

X. Fontané, L. Calvo-Barrio, V. Izquierdo-Roca, E. Saucedo, A. Pérez-Rodriguez, J.R. Morante, D.M. Berg, P.J. Dale, and S. Siebentritt, Appl. Phys. Lett. 98, 181905 (2011).

W.G. Nilsen, Phys. Rev. 182, 838 (1969).

Hyesun Yoo and JunHo Kim, Sol. Energy Mater. Sol. Cells 95, 239 (2011).

A.E. Rakhshani and S. Thomas, J. Electron. Mater. 44, 4760 (2015).

K. Wang, O. Gunawan, T. Todorov, B. Shin, S.J. Chey, N.A. Bojarczuk, D. Mitzi, and S. Guha, Appl. Phys. Lett. 97, 143508 (2010).

H. Guan, H. Shen, C. Gao, and X. He, J. Mater. Sci. Mater. Electron. 24, 2667 (2013).

M. Dhanasekar and S.V. Bhat, Appl. Surf. Sci. 418, 194 (2016).

B. Long, S. Cheng, Q. Zheng, J. Yu, and H. Jia, Mater. Res. Bull. 73, 140 (2016).

R.M. Patil, D.R. Nagapure, G.S. Mary, G.H. Chandra, M.A. Sunil, Y.V. Subbaiah, P. Prathap, M. Gupta, and R.P. Rao, J. Mater. Sci. Mater. Electron. 28, 18244 (2017).

P. Kevin, M.A. Malik, and P. O’Brien, J. Mater. Chem. C. 3, 5733 (2015).

G.G. Silvena, B. John, R.A. Christinal, M.S. Kumar, S. Chakravarty, and A.L. Rajesh, J. Inorg. Organomet. Polym Mater. 27, 1556 (2017).

F. Aslan, A. Goktaş, and A. Tumbul, Mater. Sci. Semicond. Process. 43, 139 (2016).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Prabeesh, P., Vysakh, K.V., Selvam, I.P. et al. Cu2ZnSnS4 Thin Films by Dip Coating from Metal-Thiourea Precursor Solution: Effect of Sulphurization Temperature on the Formation and Structural, Optical and Electrical Properties. J. Electron. Mater. 47, 5396–5402 (2018). https://doi.org/10.1007/s11664-018-6438-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-018-6438-8