Abstract

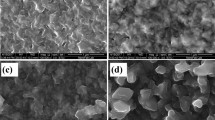

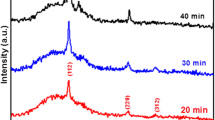

Three samples of copper sulfide Cu2S thin film were deposited on polyimide substrate by spray pyrolysis using deposition temperature of 400°C and deposition time of about 45 min. One of the samples was left as deposited, another was heat treated, while the third was laser treated. The structural, surface morphological, optical, mechanical, and electrical properties of the films were investigated. X-ray diffraction (XRD) analysis showed that the copper sulfide films were close to copper-rich phase (Cu2S). Increased crystallite size after heat and laser treatment was confirmed by XRD analysis and scanning electron microscopy. Vickers hardness measurements showed that the samples’ hardness values were enhanced with increasing crystallite size, representing an inverse Hall–Petch (H–P) effect. The calculated optical bandgap of the treated films was lower than that of the deposited film. Finally, it was found that both heat and laser treatment enhanced the physical properties of the sprayed Cu2S films on polyimide substrate for use in solar energy applications.

Similar content being viewed by others

References

M.A. Rafea, A.A.M. Farag, and N. Roushdy, Mater. Res. Bull. 47, 257 (2012). https://doi.org/10.1016/j.materresbull.2011.11.035.

C.-Y. Su, D.K. Mishra, C.-Y. Chiu, and J.-M. Ting, Surf. Coat. Technol. 231, 517 (2013). https://doi.org/10.1016/j.surfcoat.2012.03.031.

M. Orphanou, E. Leontidis, T. Kyprianidou-Leodidou, P. Koutsoukos, and K.C. Kyriacou, Langmuir 20, 5605 (2004). https://doi.org/10.1021/la036372d.

M. Xin, K. Li, and H. Wang, Appl. Surf. Sci. 256, 1436 (2009). https://doi.org/10.1016/j.apsusc.2009.08.104.

A.A. Sagade and R. Sharma, Sens. Actuators B Chem. 133, 135 (2008). https://doi.org/10.1016/j.snb.2008.02.015.

F. Li, J. Wu, Q. Qin, Z. Li, and X. Huang, Powder Technol. 198, 267 (2010). https://doi.org/10.1016/j.powtec.2009.11.018.

A. Bollero, M. Grossberg, B. Asenjo, and M. Gutiérrez, Surf. Coat. Technol. 204, 600 (2009). https://doi.org/10.1016/j.surfcoat.2009.08.037.

J.H. Rhee, Y.H. Lee, P. Bera, and S.I. Seok, Chem. Phys. Lett. 477, 345 (2009). https://doi.org/10.1016/j.cplett.2009.07.014.

A.E. Lozano, J.D. Abajo, J.G. de la Campa, C. Guillén, J. Herrero, and M.T. Gutierrez, J. Appl. Polym. Sci. 103, 3491 (2007). https://doi.org/10.1002/app.24470.

S. Mu, D. Wu, Y. Wang, Z. Wu, X. Yang, and W. Yang, ACS Appl. Mater. Interfaces 2, 118 (2009). https://doi.org/10.1021/am900620u.

M. Hasegawa and K. Horie, Prog. Polym. Sci. 26, 259 (2001). https://doi.org/10.1016/s00796700(00)00042-3.

R. Rana, J. Chakraborty, S.K. Tripathi, and M. Nasim, J. Nanostructure Chem. 6, 65 (2016). https://doi.org/10.1007/s40097-015-0177-7.

V. Krylova, Mater. Sci. Poland 25, 933 (2007).

V. Janickis, R. Maciulevičiusė, R. Ivanauskas, and I. Ancutienė, Colloid Polym. Sci. 281, 84 (2003). https://doi.org/10.1007/s00396-002-0732-x.

R. Rowe, M. Kunita, M. Porto, E. Muniz, A. Rubira, R. Nery, E. Radovanovic, L. Taylor, and N. Nazem, J. Mater. Res. 16, 3097 (2001). https://doi.org/10.1557/jmr.2001.0427.

F.A. Sabah, N.M. Ahmed, Z. Hassan, and H.S. Rasheed, Procedia Chem. 19, 15 (2016). https://doi.org/10.1016/j.proche.2016.03.005.

X. Wang, S.S. Li, C. Huang, S. Rawal, J. Howard, V. Craciun, T. Anderson, and O. Crisalle, Sol. Energy Mater. Sol. Cells 88, 65 (2005). https://doi.org/10.1016/j.solmat.2004.06.020.

B.J. Simonds, H.J. Meadows, S. Misra, C. Ferekides, P.J. Dale, and M.A. Scarpulla, J. Photon. Energy 5, 050999 (2015). https://doi.org/10.1117/1.jpe.5.050999.

V. Janickis, R. Maciulevičius, R. Ivanauskas, and I. Ancutienė, Mater. Sci. Poland 23, 715 (2005).

F.H. Alsultany, N.M. Ahmed, and M. Matjafri, Soft Nanosci. Lett. 4, 83 (2014). https://doi.org/10.4236/snl.2014.44012.

F. Mahmoud, W. Magdy, A.-S. Gadallah, M. Nasr, and I. Azzouz, J. Mater. Sci.: Mater. Electron. 28, 6284 (2017). https://doi.org/10.1007/s10854-016-6310-7.

A.I. Khudiar, M. Zulfequar, and Z.H. Khan, Chalcogenide Lett. 7, 291 (2010).

P. Shindov, R. Kakanakov, L. Kolaklieva, S. Kaneva, T. Anastasova, 26th International Conference on Microelectronics, MIEL 2008, vol. 243 (IEEE, 2008). https://doi.org/10.1109/icmel.2008.4559269

R. Kale and C. Lokhande, Semicond. Sci. Technol. 20, 1 (2004). https://doi.org/10.1088/0268-1242/20/1/001.

B. Bharathi, S. Thanikaikarasan, P. Kollu, P. Chandrasekar, K. Sankaranarayanan, and X.S. Shajan, J. Mater. Sci.: Mater. Electron. 25, 5338 (2014). https://doi.org/10.1007/s10854-014-2310-7.

R.S. Reddy, A. Sreedhar, A.S. Reddy, and S. Uthanna, Adv. Mater. Lett. 3, 239 (2012). https://doi.org/10.5185/amlett.2012.3329.

S. Thanikaikarasan, K. Sundaram, T. Mahalingam, S. Velumani, and J.-K. Rhee, Mater. Sci. Eng., B 174, 242 (2010). https://doi.org/10.1016/j.mseb.2010.03.054.

T.E. Manjulavalli and A.G. Kannan, Int. J. Chemtech. Res. 8, 607 (2015).

M.A. Meyers, A. Mishra, and D.J. Benson, Prog. Mater Sci. 51, 427 (2006). https://doi.org/10.1016/j.pmatsci.2005.08.003.

M. Dao, L. Lu, R. Asaro, J.T.M. De Hosson, and E. Ma, Acta Mater. 55, 4041 (2007). https://doi.org/10.1016/j.actamat.2007.01.038.

H. Conrad, Metall. Mater. Trans. A 35, 2681 (2004). https://doi.org/10.1007/s11661-004-0214-5.

C. Schuh, T. Nieh, and T. Yamasaki, Scr. Mater. 46, 735 (2002). https://doi.org/10.1016/s13596462(02)00062-3.

A. Giga, Y. Kimoto, Y. Takigawa, and K. Higashi, Scr. Mater. 55, 143 (2006). https://doi.org/10.1016/j.scriptamat.2006.03.047.

J. Schiøtz and K.W. Jacobsen, Science 301, 1357 (2003). https://doi.org/10.1126/science.1086636.

X. Li, Y. Wei, L. Lu, K. Lu, and H. Gao, Nature 464, 877 (2010). https://doi.org/10.1038/nature08929.

D. Wolf, V. Yamakov, S. Phillpot, A. Mukherjee, and H. Gleiter, Acta Mater. 53, 1 (2005). https://doi.org/10.1016/j.actamat.2004.08.045.

C.C. Koch and J. Narayan, Mater. Res. Soc. Symp. Proc. (2000). https://doi.org/10.1557/proc634-b5.1.1.

J. Narayan, J. Nanopart. Res. 2, 91 (2000).

Z. Qi, P. Sun, F. Zhu, Z. Wang, D. Peng, and C. Wu, Surf. Coat. Technol. 205, 3692 (2011). https://doi.org/10.1016/j.surfcoat.2011.01.021.

X. Liu, F. Yuan, and Y. Wei, Appl. Surf. Sci. 279, 159 (2013). https://doi.org/10.1016/j.apsusc.2013.04.062.

M. Adelifard, H. Eshghi, and M.M.B. Mohagheghi, Appl. Surf. Sci. 258, 5733 (2012). https://doi.org/10.1016/j.apsusc.2012.02.079.

L. Isac, L. Andronic, A. Enesca, and A. Duta, J. Photochem. Photobiol. A Chem. 252, 53 (2013). https://doi.org/10.1016/j.jphotochem.2012.11.011.

H. Zhu, D. Yang, G. Yu, H. Zhang, and K. Yao, Nanotechnology 17, 2386 (2006). https://doi.org/10.1088/0957-4484/17/9/052.

N. Rajesh, J. Kannan, T. Krishnakumar, and G. Neri, Acta Phys. Pol., A 125, 1229 (2014). https://doi.org/10.12693/aphyspola.125.1229.

A.I. Khudiar, Siddhartha, M. Zulfequar, and Z.H. Khan, Chalcogenide Lett. 7, 361 (2010).

Z. Alaie, M. Nejad, and M. Yousefi, Int. J. Nanosci. Nanotechnol. 12, 119 (2016).

H. He, F. Zhuge, Z. Ye, L. Zhu, F. Wang, B. Zhao, and J. Huang, J. Appl. Phys. 99, 023503 (2006). https://doi.org/10.1063/1.2161419.

N.K. Allouche, T.B. Nasr, C. Guasch, and N.K. Turki, C. R. Chim. 13, 1364 (2010). https://doi.org/10.1016/j.crci.2010.04.012.

A. Al-Ghamdi, S.A. Khan, S. Al-Heniti, F. Al-Agel, T. Al-Harbi, and M. Zulfequar, J. Alloys Compd. 505, 229 (2010). https://doi.org/10.1016/j.jallcom.2010.06.035.

H. Lee, J.W. Park, and H. Lee, J. Kor. Phys. Soc. 56, 625 (2010). https://doi.org/10.3938/jkps.56.625.

P. More, S. Dhanayat, K. Gattu, S. Mahajan, D. Upadhye, R. Sharma, in AIP Conference Proceedings, vol 020489 (AIP Publishing, 2016). https://doi.org/10.1063/1.4946540

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Magdy, W., Mahmoud, F.A. & Nassar, A.H. Effect of Heat and Laser Treatment on Cu2S Thin Film Sprayed on Polyimide Substrate. J. Electron. Mater. 47, 2640–2647 (2018). https://doi.org/10.1007/s11664-018-6102-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-018-6102-3