Abstract

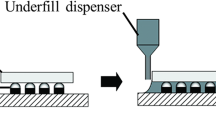

Voids have always been present using the molded underfill (MUF) package process, which is a problem that needs further investigation. In this study, the process was studied using the Moldex3D numerical analysis software. The effects of gas (air vent effect) on the overall melt front were also considered. In this isothermal process containing two fluids, the gas and melt colloid interact in the mold cavity. Simulation enabled an appropriate understanding of the actual situation to be gained, and, through analysis, the void region and exact location of voids were predicted. First, the global flow end area was observed to predict the void movement trend, and then the local flow ends were observed to predict the location and size of voids. In the MUF 518 case study, simulations predicted the void region as well as the location and size of the voids. The void phenomenon in a flip chip ball grid array underfill is discussed as part of the study.

Similar content being viewed by others

References

J.H. Lau, Ball grid array technology (New York: McGraw-Hill, 1994).

K. Chai and L. Wu, in Proceeding of the 1st International IEEE Conference on Polymers and Adhesives in Microelectronics and Photonics (2001), p. 119.

K. Chai, E. Wu, and J.Y. Tong, in Proceeding of the 1st International IEEE Conference on Polymers and Adhesives in Microelectronics and Photonics (2002), p. 221.

C.K. Chee, S.S. Lim, V.A. Rudge, S. Periaman, A.L. Ong, H.W. Chan, and E. Then, in Electronic Components and Technology Conferences (2003), p. 962.

H.T. Ming and L. Khor, in Electronic Manufacturing Technology Symposium, IEEE/CPMT International (2008), p. 1.

M.W. Lee, W.K. Jung, E.S. Sohn, J.Y. Lee, C.H. Hwang, and C.H. Lee, in Electronic Components and Technology Conference (2008), p. 382.

J. Tamil, S.H. Ore, K.Y. Gan, Y.Y. Bo, G. Ng, P.T. Wah, N. Suthiwongsunthorn, and C. Chungpaiboonpatana, in 44th International Symposium on Microelectronics (2011), p. 673.

C.H. Chen, Simulation of Filling and Curing Process in Epoxy Reactive (Hsinchu: National Tsing Hua University, 1995).

L.C. Hong, Study of Warpage Due to P–V–T–C Relation of EMC in IC Packaging (Tainan: Nation Cheng Kung University, 2004).

J. Tamil, S.H. Ore, K.Y. Gan, Y.Y. Bo, G. Ng, P.T. Wah, N. Suthiwongsunthorn, and C. Chungpaiboonpatan, IMAPS. 9, 1 (2012).

R.Y. Chang, Study on the Three-Dimensional Flow Analysis of Viscoelastic Fluids in Injection Molding Process (CHE Projects, NSC-89-2216-E007-018, Taiwan, 2000).

Acknowledgements

The authors wish to thank Mr. Yu-Kai Chen for assistance with the experiments and the Taiwan ASE group for provided the experimental data in the production process.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, KT., Hwang, SJ. & Lee, HH. Mechanism of Void Prediction in Flip Chip Packages with Molded Underfill. J. Electron. Mater. 46, 5094–5106 (2017). https://doi.org/10.1007/s11664-017-5516-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-017-5516-7