Abstract

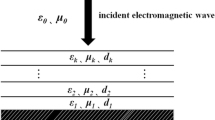

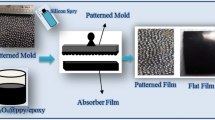

A square frequency-selective surface (FSS) design has been employed to improve the microwave absorption properties of carbon black/silicone rubber (CBSR) composite coating. The FSS is placed on the surface of the CBSR coating. The effects of FSS design parameters on the microwave absorption properties of the CBSR coating have been investigated, including the size and period of the FSS design, and the thickness and permittivity of the coating. Simulation results indicate that the absorption peak for the CBSR coating alone is related to its thickness and electromagnetic parameters, while the combination of the CBSR coating with a FSS can exhibit a new absorption peak in the reflection curve; the frequency of the new absorption peak is determined by the resonance of the square FSS design and tightly depends on the size of the squares, with larger squares in the FSS design leading to a lower frequency of the new absorption peak. The enhancement of the absorption performance depends on achievement of a new absorption peak using a suitable␣size and period of the FSS design. In addition, the FSS design has a stable␣frequency response for both transverse electromagnetic (TE) and transverse magnetic (TM) polarizations as the incident angle varies from 0° to 40°. The optimized results indicate that the bandwidth with reflection loss below −5 dB can encompass the whole frequency range from 8 GHz to 18 GHz for thickness of the CBSR coating of only 1.8 mm. The simulation results are confirmed by experiments.

Similar content being viewed by others

References

D.D.L. Chung, Carbon 39, 279 (2001).

G. Mu, N. Chen, X. Pan, H. Shen, and M. Gu, Mater. Lett. 62, 840 (2008).

Y.B. Feng, T. Qiu, C.Y. Shen, and X.Y. Li, IEEE Trans. Magn. 42, 363 (2006).

N. Joseph, S.K. Singh, R.K. Sirugudu, V.R.K. Murthy, S. Ananthakumar, and M.T. Sebastian, Mater. Res. Bull. 48, 1681 (2013).

W.S. Chin and D.G. Lee, Compos. Struct. 77, 457 (2007).

N. Joseph and M.T. Sebastian, Mater. Lett. 90, 64 (2013).

K.Y. Park, S.E. Lee, C.G. Kim, and J.H. Han, Compos. Sci. Technol. 66, 576 (2006).

S. Vinayasree, M.A. Soloman, V. Sunny, P. Mohanan, P. Kurian, P.A. Joy, and M.R. Anantharaman, J. Appl. Phys. 116, 024902 (2014).

N. Joseph, C. Janardhanan, and M.T. Sebastian, Compos. Sci. Technol. 101, 139 (2014).

L. Zhou, S. Cui, Y. Zhai, F. Luo, and Y. Dong, Ceram. Int. 41, 14908 (2015).

Z. Yang, F. Luo, J. Xu, W. Zhou, and D. Zhu, J. Alloy. Compd. 662, 607 (2016).

N.I. Landy, S. Sajuyigbe, J.J. Mock, D.R. Smith, and W.J. Padilla, Phys. Rev. Lett. 100, 207402 (2008).

H. Tao, N.I. Landy, C.M. Bingham, X. Zhang, R.D. Averitt, and W.J. Padilla, Opt. Express 16, 7181 (2008).

H.T. Liu, H.F. Cheng, Z.Y. Chu, and D.Y. Zhang, Mater. Des. 28, 2166 (2007).

D. Wan, S.W. Bie, J. Zhou, H. Xu, Y. Xu, and J. Jiang, Progr. Electromagn. Res. C 56, 93 (2015).

Z. Yang, F. Luo, M. Sun, J. Xu, W. Zhou, Y. Qing, D. Zhu, and Z. Huang, Mater. Lett. 151, 109 (2015).

J.H. Oh, K.S. Oh, C.G. Kim, and C.S. Hong, Compos. Part B 35, 49 (2004).

A.A. Barba, G. Lamberti, M. d’Amore, and D. Acierno, Polym. Bull. 57, 587 (2006).

S. Vinayasree, M.A. Soloman, V. Sunny, P. Mohanan, P. Kurian, and M.R. Anantharaman, Compos. Sci. Technol. 82, 69–75 (2013).

S.K. Kwon, J.M. Ahn, G.H. Kim, C.H. Chun, J.S. Hwang, and J.H. Lee, Polym. Eng. Sci. 42, 2165 (2002).

H. Sun, R. Che, X. You, Y. Jiang, Z. Yang, J. Deng, L. Qiu, and H. Peng, Adv. Mater. 26, 8120 (2014).

F.L. Traversa, M.D. Ventra, and F. Bonani, Phys. Rev. Lett. 110, 170602 (2013).

A. Ohlan, K. Singh, A. Chandra, and S.K. Dhawan, ACS Appl. Mater. Interfaces 2, 927 (2010).

N.F. Colaneri and L.W. Schacklette, IEEE Trans. Instrum. Meas. 41, 291 (1992).

W.H. Choi, J.H. Shin, T.H. Song, J.B. Kim, C.M. Cho, W.J. Lee, and C.G. Kim, IEEE Trans. Electromagn. Compat. 56, 599 (2014).

S.S. Kim, S.B. Jo, K.I. Gueon, K.K. Choi, J.M. Kim, and K.S. Churn, IEEE Trans. Magn. 27, 5462 (1991).

J. Huo, L. Wang, and H. Yu, J. Mater. Sci. 44, 3917 (2009).

V.K. Singh, A. Shukla, M.K. Patra, L. Saini, R.K. Jani, S.R. Vadera, and N. Kumar, Carbon 50, 2202 (2012).

G.L.R. Araujo, A.L.P.S. Campos, and A.D.M. Martins, Progr. Electromagn. Res. Lett. 55, 67 (2015).

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No.␣51402239), Fundamental Research Funds for the Central Universities (No. 3102014JCY01002), and State Key Laboratory of Solidification Processing (NWPU), China (Grant No. KP201422).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, Z., Luo, F., Gao, L. et al. Enhanced Microwave Absorption Properties of Carbon Black/Silicone Rubber Coating by Frequency-Selective Surface. J. Electron. Mater. 45, 5017–5023 (2016). https://doi.org/10.1007/s11664-016-4671-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-016-4671-6