Abstract

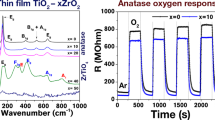

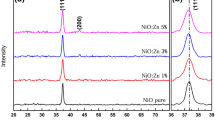

Anatase titanium dioxide (TiO2) thin films were deposited onto cleaned glass substrates by a direct current (DC) reactive magnetron sputtering technique for different deposition times from 10 min to 40 min, which resulted in films of different thicknesses. Characterization techniques, such as x-ray diffraction (XRD) and field emission-scanning electron microscopy (FE-SEM) were used to characterize the structural and morphological properties of the TiO2 thin films. XRD patterns showed the formation of (101) crystal anatase facets. The grain size values of the film increased with increased deposition time, and the films deposited at 40 min exhibited a porous structure. Anatase TiO2 thin films exhibited excellent sensing response, fast response and recovery time, as well as good stability and selectivity towards ammonia (NH3). The enhanced NH3 sensing behavior of anatase TiO2 films is attributed to the porous morphology and oxygen vacancies.

Similar content being viewed by others

References

Y. Zilberman, Y. Chen, and S.R. Sonkusale, Sens. Actuators, B 202, 976 (2014).

Y. Jia, C. Yan, H. Yu, L. Chen, and F. Dong, Sens. Actuators B203, 459 (2014).

G.N. Dar, A. Umar, S.A. Zaidi, S. Baskoutas, S.W. Hwang, M. Abaker, A. Al-Hajry, and S.A. Al-Sayari, Talanta 89, 155 (2012).

S.A. Krutovertsev, S.I. Sorokin, A.V. Zorin, Y.A. Letuchy, and O.Y. Antonova, Sens. Actuators B7, 492 (1992).

S. Sharma, S. Hussain, S. Singh, and S.S. Islam, Sens. Actuators B194, 213 (2014).

A.K. Singh, M.A. Uddin, J.T. Tolson, H. Maire-Afeli, N. Sbrockey, G.S. Tompa, M.G. Spencer, T. Vogt, T.S. Sudarshan, and G. Koley, Appl. Phys. Lett. 102, 043101 (2013).

A. Singh, M.A. Uddin, T. Sudarshan, and G. Koley, Small 10, 1555 (2014).

Y.-F. Sun, S.-B. Liu, F.-L. Meng, J.-Y. Liu, Z. Jin, L.-T. Kong, and J.-H. Liu, Sensors 12, 2610 (2012).

M.E. Franke, T.J. Koplin, and U. Simon, Small 2, 36 (2006).

W. Ong, L. Tan, S. Chai, and S. Yong, Nanoscale 6, 1946 (2014).

P. Dhivya and M. Sridharan, J. Electron. Mater. 43, 3211 (2014).

D.R. Patil, L.A. Patil, and P.P. Patil, Sens. Actuators B 126, 368 (2007).

U.V. Patil, N.S. Ramgir, N. Karmakar, A. Bhogale, A.K. Debnath, D.K. Aswal, S.K. Gupta, and D.C. Kothari, Appl. Surf. Sci. 339, 69 (2015).

S. Mun, Y. Chen, and J. Kim, Sens. Actuators, B 171–172, 1186 (2012).

S.G. Wang, Q. Zhang, D.J. Yang, P.J. Sellin, and G.F. Zhong, Diam. Relat. Mater. 13, 1327 (2004).

P. Dhivya, A.K. Prasad, and M. Sridharan, J. Alloys Compd. 620, 109 (2015).

P. Dhivya, A.K. Prasad, and M. Sridharan, Ceram. Int. 40, 409 (2014).

T. Bora, H. Fallah, M. Chaudhari, and T. Apiwattanadej, Sens. Actuators, B 202, 543 (2014).

P. Dhivya, A.K. Prasad, and M. Sridharan, J. Solid State Chem. 214, 24 (2014).

M. Sharma and R.M. Mehra, Appl. Surf. Sci. 255, 2527 (2008).

M.M.S. Muthukumaran, J. Mater. Sci.: Mater. Electron. 24, 2277 (2013).

P. Dhivya and M. Sridharan, International Conference on Advanced Nanomaterials and Emerging Engineering Technologies (2013), pp. 547–553.

Z. Ting, Y. Jiang, D. Ling-hong, and Z. Wei-feng, Chin. Phys. B 22, 117801 (2013).

M. Ulrich, A. Bunde, and C.D. Kohl, Appl. Phys. Lett. 85, 242 (2004).

M. Ulrich, C.D. Kohl, and A. Bunde, Thin Solid Films 391, 299 (2001).

V. Modafferi, G. Panzera, A. Donato, P.L. Antonucci, C. Cannilla, N. Donato, D. Spadaro, and G. Neri, Sens. Actuators B 163, 61 (2012).

D.E. Williams, Sens. Actuators B57, 1 (1999).

S. Sharma and M. Madou, Philos. Trans. R. Soc. A 370, 2448 (2012).

D.A. Links, CrystEngComm 14, 3283 (2012).

Q. Feng, Y.-X. Yue, W.-H. Wang, and H.-Q. Zhu, Chin. Phys. B 23, 043101 (2014).

J. Huang, H. Ren, P. Sun, C. Gu, Y. Sun, and J. Liu, Sens. Actuators, B 188, 249 (2013).

T. Sato, M. Breedon, and N. Miura, Sensors (Basel) 12, 4706 (2012).

E. Gallego, X. Roca, J.F. Perales, and X. Guardino, J. Environ. Sci. 21, 333 (2009).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ponnusamy, D., Madanagurusamy, S. Porous Anatase TiO2 Thin Films for NH3 Vapour Sensing. J. Electron. Mater. 44, 4726–4733 (2015). https://doi.org/10.1007/s11664-015-4099-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-015-4099-4