Abstract

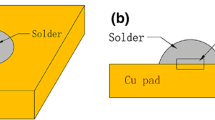

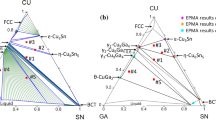

The growth of intermetallic compounds (IMCs) on the free surface of 99Sn-1Cu solder joints perpendicular to the interdiffusion direction has been investigated in this work. The specimens were specifically designed and polished to reveal a flat free surface at the solder/Cu interface for investigation. After aging at 175°C for progressively increased durations, the height of the perpendicular IMCs was examined and found to follow a parabolic law with aging duration that could be expressed as \(y = 0.11\sqrt t\), where t is the aging duration in hours and y is the height of the perpendicular IMCs in μm. For comparison, the planar growth of IMCs along the interdiffusion direction was also investigated in 99Sn-1Cu/Cu solder joints. After prolonged aging at 175°C, the thickness of the planar interfacial IMC layers also increased parabolically with aging duration and could be expressed as \(h_{\rm{IMC}} = 0.27\sqrt t + 4.6\), where h is the thickness in μm and t is the time in hours. It was found that both the planar and perpendicular growth of the IMCs were diffusion-controlled processes, but the perpendicular growth of the IMCs was much slower than their planar growth due to the longer diffusion distance. It is proposed that Cu3Sn forms prior to the formation of Cu6Sn5 in the perpendicular IMCs, being the reverse order compared with the planar IMC growth.

Similar content being viewed by others

References

Y. Ping-Feng, L. Yi-Shao, S.-R. Jian, and C. Jiunn, 8th International Conference on Electronic Packaging Technology, Shanghai, 14–17 August, 2007, pp. 1–5.

L. Jiang, H. Jiang, and N. Chawla, J. Electron. Mater. 41, 2083 (2012).

Q.K. Zhang, J. Tan, and Z.F. Zhang, J. Appl. Phys. 110, 014502 (2011).

S.W.R. Lee and S. Fubin, International Microsystems, Packaging, Assembly Conference Taiwan 2006, Taipei, 18–20 October, 2006, pp. 105–108.

J.H.L. Pang, T.H. Low, B.S. Xiong, X. Luhua, and C.C. Neo, Thin Solid Films 462–463, 370 (2004).

J.-W. Yoon, S.-W. Kim, and S.-B. Jung, Mater. Trans. 45, 727 (2004).

Y. Liu and F. Sun, J. Mater. Sci. Mater. Electron. 24, 290 (2013).

C. Chen, H.-Y. Hsiao, Y.-W. Chang, F. Ouyang, and K.N. Tu, Mater. Sci. Eng. R. 73, 85 (2012).

T.Y. Lee, K.N. Tu, and D.R. Frear, J. Appl. Phys. 90, 4502 (2001).

C.-M. Chen and C.-H. Chen, J. Electron. Mater. 36, 1363 (2007).

Y.S. Kaganovskii, L.N. Paritskaya, V.V. Bogdanov, and A.O. Grengo, Acta Mater. 45, 3927 (1997).

J. Gong, C. Liu, P.P. Conway, and V.V. Silberschmidt, Scripta Mater. 60, 333 (2009).

C.Y. Liu and K.N. Tu, J. Mater. Res. 13, 37 (1998).

Y.S. Kaganovskii, L.N. Paritskaya, and V.V. Bogdanov, Powder Metall. Met. C+ 47, 652 (2008).

Y.C. Chan, A.C.K. So, and J.K.L. Lai, Mater. Sci. Eng. B 55, 5 (1998).

W. Peng, E. Monlevade, and M.E. Marques, Microelectron. Reliab. 47, 2161 (2007).

X. Li, F. Li, F. Guo, and Y. Shi, J. Electron. Mater. 40, 51 (2011).

Z. Huijing, Q. Lin, L. Hua, Z. Ning, and M. HaiTao, 14th International Conference on Electronic Packaging Technology, Dalian, 11–14 August, 2013, pp. 372–376.

H. Xiao, X.Y. Li, Y.X. Zhu, J.L. Yang, J. Chen, and F. Guo, J. Mater. Sci. Mater. Electron. 24, 2527 (2013).

T.-T. Luu, A. Duan, K. Aasmundtveit, and N. Hoivik, J. Electron. Mater. 42, 3582 (2013).

H.K. Kim, H.K. Liou, and K.N. Tu, J. Mater. Res. 10, 497 (1995).

X. Chen, Z. Yun, F. Chonglun, and J.A. Abys, IEEE Trans. Electron. Packag. Manuf. 28, 31 (2005).

M.Y. Tsai, S.C. Yang, Y.W. Wang, and C.R. Kao, J. Alloys Compd. 494, 123 (2010).

T. Laurila, V. Vuorinen, and J.K. Kivilahti, Mater. Sci. Eng. R. 49, 1 (2005).

K.N. Tu and R.D. Thompson, Acta Metall. Mater. 30, 947 (1982).

B.-J. Lee, N.M. Hwang, and H.M. Lee, Acta Mater. 45, 1867 (1997).

R.A. Gagliano, G. Ghosh, and M.E. Fine, J. Electron. Mater. 31, 1195 (2002).

X. Deng, G. Piotrowski, J.J. Williams, and N. Chawla, J. Electron. Mater. 32, 1403 (2003).

Z. Kejun, R. Stierman, C. Tz-Cheng, D. Edwards, K. Ano, and K.N. Tu, J. Appl. Phys. 97, 024508 (2005).

C.-C. Pan, C.-H. Yu, and K.-L. Lin, Appl. Phys. Lett. 93, 061912 (2008).

Y. Wu, J. Sees, C. Pouraghabagher, L.A. Foster, J. Marshall, E. Jacobs, and R. Pinizzotto, J. Electron. Mater. 22, 769 (1993).

H.L.J. Pang, K.H. Tan, X.Q. Shi, and Z.P. Wang, Mater. Sci. Eng. A 307, 42 (2001).

C. Yu, Y. Yang, J. Chen, J. Xu, J. Chen, and H. Lu, Mater. Lett. 128, 9 (2014).

J.Y. Song, J. Yu, and T.Y. Lee, Scripta Mater. 51, 167 (2004).

K.N. Tu, C. Chen, and A. Wu, J. Mater. Sci. Mater. Electron. 18, 269 (2007).

M. Kawano, S. Uchiyama, Y. Egawa, N. Takahashi, Y. Kurita, K. Soejima, M. Komuro, S. Matsui, K. Shibata, J. Yamada, M. Ishino, H. Ikeda, Y. Saeki, O. Kato, H. Kikuchi, and T. Mitsuhashi, International Electron Devices Meeting 2006, San Francisco, 11–13 December, 2006, pp. 1–4.

Y. Seung Wook, K. Jae Hoon, N. Suthiwongsunthorn, P.C. Marimuthu, and F. Carson, IEEE International Conference on 3D System Integration 2009, San Francisco, 28–30 September, 2009, pp. 1–5.

J. Brusse, G. Ewell, and J. Siplon, 22nd Capacitor and Resistor Technology Symposium, New Orleans, 25–29 March, 2002, pp. 67–80.

C.Y. Khor, M.Z. Abdullah, Z.M. Ariff, and W.C. Leong, Int. Commun. Heat Mass. 39, 670 (2012).

Acknowledgements

Z.C. would like to acknowledge the joint PhD programme between Loughborough University (UK) and Huazhong University of Science and Technology (China). This research was also supported by a Marie Curie International Research Staff Exchange Scheme Project within the 7th European Community Framework Programme, No. PIRSES-GA-2010-269113, entitled “Micro-Multi-Material Manufacture to Enable Multifunctional Miniaturised Devices (M6),” as well as the National Natural Science Foundation of China (No. 60976076).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, Z., Liu, C., Wu, Y. et al. Perpendicular Growth Characteristics of Cu-Sn Intermetallic Compounds at the Surface of 99Sn-1Cu/Cu Solder Interconnects. J. Electron. Mater. 44, 4836–4845 (2015). https://doi.org/10.1007/s11664-015-4043-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-015-4043-7