Abstract

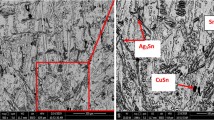

This work investigates the effects of 0.1 wt.% and 0.5 wt.% Al additions on bulk alloy microstructure and tensile properties as well as on the thermal behavior of Sn-1Ag-0.5Cu (SAC105) lead-free solder alloy. The addition of 0.1 wt.% Al reduces the amount of Ag3Sn intermetallic compound (IMC) particles and leads to the formation of larger ternary Sn-Ag-Al IMC particles. However, the addition of 0.5 wt.% Al suppresses the formation of Ag3Sn IMC particles and leads to a large amount of fine Al-Ag IMC particles. Moreover, both 0.1 wt.% and 0.5 wt.% Al additions suppress the formation of Cu6Sn5 IMC particles and lead to the formation of larger Al-Cu IMC particles. The 0.1 wt.% Al-added solder shows a microstructure with coarse β-Sn dendrites. However, the addition of 0.5 wt.% Al has a great effect on suppressing the undercooling and refinement of the β-Sn dendrites. In addition to coarse β-Sn dendrites, the formation of large Sn-Ag-Al and Al-Cu IMC particles significantly reduces the elastic modulus and yield strength for the SAC105 alloy containing 0.1 wt.% Al. On the other hand, the fine β-Sn dendrite and the second-phase dispersion strengthening mechanism through the formation of fine Al-Ag IMC particles significantly increases the elastic modulus and yield strength of the SAC105 alloy containing 0.5 wt.% Al. Moreover, both 0.1 wt.% and 0.5 wt.% Al additions worsen the elongation. However, the reduction in elongation is much stronger, and brittle fracture occurs instead of ductile fracture, with 0.5 wt.% Al addition. The two additions of Al increase both solidus and liquidus temperatures. With 0.5 wt.% Al addition the pasty range is significantly reduced and the differential scanning calorimetry (DSC) endotherm curve gradually shifts from a dual to a single endothermic peak.

Similar content being viewed by others

References

M. Abtew and G. Selvaduray, Mater. Sci. Eng. R 27, 95 (2000).

K.N. Subramanian, A. Lee, S. Choi, and P. Sonje, J. Electron. Mater. 30, 372 (2001).

J.L. Pang, L. Xu, X.Q. Shi, W. Zhou, and S.L. Ngoh, J. Electron. Mater. 33, 1219 (2004).

D. Li, C. Liu, and P.P. Conway, J. Electron. Mater. 35, 388 (2006).

I.E. Anderson, J.C. Foley, B.A. Cook, J. Harringa, R.L. Terpstra, and O. Unal, J. Electron. Mater. 30, 1050 (2001).

S. Terashima, Y. Kariya, T. Hosoi, and M. Tanaka, J. Electron. Mater. 32, 1527 (2003).

D.A. Shnawah, M.F.M. Sabri, and I.A. Badruddin, Microelectron. Reliab. 52, 90 (2012).

A. Syed, J. Scanlan, S. Cha, W. Kang, E. Sohn, T. Kim, and C.G. Ryu, IEEE Proceedings of the 58th Electronic components and technology conference (ECTC’05) (2005), p. 1453.

D. Suh, D.W. Kim, P. Liu, H. Kim, J.A. Weninger, C.M. Kumar, A. Prasad, B.W. Grimsley, and H.B. Tejada, Mater. Sci. Eng. A 460–461, 595 (2007).

D. Kim, D. Suh, T. Millard, H. Kim, C. Kumar, M. Zhu, and Y. Xu, IEEE Proceedings of the 57th Electronic components and technology conference (ECTC’07) (2007), p. 1614.

W. Kittidacha, A. Kanjanavikat, and K. Vattananiyom, IEEE Proceedings of the 10th Electronic components and technology conference (ECTC’08) (2008), p. 1074.

Y. Kariya, T. Hossi, S. Terashima, M. Tanaka, and M. Otsuka, J. Electron. Mater. 33, 321 (2004).

D.A. Shnawah, M.F.M. Sabri, I.A. Badruddin, and S. Said, Microelectron. Int. 29, 47 (2012).

S. Terashima, Y. Kariya, and M. Tanaka, Mater. Trans. 45, 673 (2004).

M. Tanaka, T. Sasaki, T. Kobayashi, and K. Tatsumi, IEEE Proceedings of the 56th Electronic components and technology conference (ECTC’09) (2007), p. 78.

R. Pandher and R. Healey, IEEE Proceedings of the 58th Electronic components and technology conference (ECTC’08) (2008), p. 2018.

W. Liu, P. Bachorik, and N-C. Lee, IEEE Proceedings of the 10th Electronics Packaging Technology Conference (EPTC’08) (2008), p. 1046.

H.Y. Songa, Q.S. Zhua, Z.G. Wanga, J.K. Shanga, and M. Luc, Mater. Sci. Eng. A 527, 1343 (2010).

A.-M. Yu, C.-W. Lee, M.-S. Kim, and J.-H. Lee, Met. Mater. Int. 13, 517 (2007).

A.K. Gain, T. Fouzder, Y.C. Chan, A. Sharif, N.B. Wong, and W.K.C. Yung, J. Alloys Compd. 506, 216 (2010).

Y.-K. Jee, Y.-H. Xia, J. Yu, H.-W. Kang, and T.-Y. Lee, IEEE Proceedings of the 58th Electronic components and technology conference (ECTC’08) (2008), p. 491.

H.R. Kotadia, O. Mokhtari, M. Bottrill, M.P. Clode, M.A. Green, and S.H. Mannan, J. Electron. Mater. 39, 2720 (2010).

B. Huang, H.-S. Hwang, and N.-C. Lee, IEEE Proceedings of the 57th Electronic components and technology conference (ECTC’07) (2007), p. 184.

C. Wei, Y.C. Liu, L.M. Yu, H. Chen, and X. Wang, Microelectron. Reliab. 50, 1142 (2010).

Y.W. Lee, I.H. Kim, E.S. Kim, J.H. Lee, and J.T. Moon, IEEE Proceedings of the 12th Electronics Packaging Technology Conference (EPTC’10) (2010), p. 429.

Y. Kariya, Y. Hirata, and M. Otsuka, J. Electron. Mater. 28, 1263 (1999).

F. Zhang, M. Li, B. Balakrisman, and W.T. Chen, J. Electron. Mater. 31, 1256 (2002).

M. Hanson and K. Anderko, Constitution of Binary Alloys, 2nd ed. (New York: McGraw-Hill, 1985), p. 1.

M. Hanson and K. Anderko, Constitution of Binary Alloys, 2nd ed. (New York: McGraw-Hill, 1985), p. 84.

M. Hanson and K. Anderko, Constitution of Binary Alloys, 2nd ed. (New York: McGraw-Hill, 1985), p. 135.

G.E. Dieter, Mechanical Metallurgy, 2nd ed. (Tokyo: McGraw-Hill, 1976), p. 222.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shnawah, D.AA., Said, S.B.M., Sabri, M.F.M. et al. Microstructure and Tensile Properties of Sn-1Ag-0.5Cu Solder Alloy Bearing Al for Electronics Applications. J. Electron. Mater. 41, 2073–2082 (2012). https://doi.org/10.1007/s11664-012-2135-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-012-2135-1