Abstract

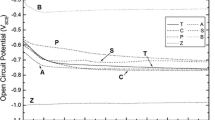

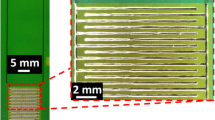

The oxidation behavior of various Sn-Zn(-Bi) alloys during 60°C/90% and 85°C/85% relative humidity (RH) exposure were investigated by microstructure observation and x-ray diffraction analysis. The mechanical property of the joints of resistor chips (1608R) with two kinds of terminations, Sn and Sn-10Pb, soldered on a printed circuit board with Sn-Zn(-Bi) were evaluated by a shear test. The heat/humidity exposure of Sn-Zn alloys promotes segregation into the grain boundary accompanying oxidation of Zn resulting in the ZnO formation. This segregation induces serious degradation of alloys and Sn whisker growth. Heat/humidity exposure of 85°C/85%RH seriously decreases the shear strength of the surface mounted chip joints, especially Sn-Zn-Bi solder, due to the formation of ZnO at the interface between the solder and the reaction layer. The presence of Bi or Pb in Sn-Zn alloys enhances the diffusion, resulting in severe degradation at 85°C/85%RH exposure. In contrast, the exposure at 60°C/90%RH does not influence the joint strength for up to 1000 h. Under this condition, the oxidation of Zn only reaches a few microns in depth from the free surface.

Similar content being viewed by others

References

M. McCormack and S. Jin, JOM 45, 36 (1993).

C. Melton, JOM 45, 33 (1993).

K. Suganuma, Y. Nakamura, and K. Nihara, J. Mater. Res. 13, 2859 (1998).

E.P. Wood and K.L. Nimmo, J. Electron. Mater. 23, 709 (1994).

M.E. Loomans, S. Vaynman, G. Gosh, and M.E. Fine, J. Electron. Mater. 23, 741 (1994).

K. Suganuma, T. Murata, H. Noguchi, and Y. Toyoda, J. Mater. Res. 15, 884 (2000).

K.-S. Kim, Y.-S. Kim, K. Suganuma, and H. Nakajima, J. Jpn. Inst. Electron. Packaging 5, 666 (2002).

S.W. Yoon, W.K. Choi, and H.M. Lee, Scripta Mater. 40, 327 (1999).

T. Kiga, S. Hattori, and Y. Iwanabe, J. Jpn. Inst. Electron. Packaging 6, 420 (2003).

M. Kitajima, T. Shono, T. Ogino, T. Kobayashi, K. Yamazaki, and M. Noguchi, J. Jpn. Inst. Electron. Packaging 6, 433 (2003).

K. Young-Sun, C.W. Hwang, and K. Suganuma, Proc. Int. Conf. on Electronics Packaging (2001 ICEP) (Tokyo, Japan: Japan Institute of Electronics Packaging/IMAPS, 2001), pp. 84–87.

M. Abtew and G. Selvaduray, Mater. Sci. Eng. 27, 95 (2000).

U. Lindborg, Acta Metall. 24, 181 (1976).

K.N. Tu, Phys. Rev. B: Condens. Matter Mater. Phys. 49, 2030 (1994).

K.N. Tu, Mater. Chem. Phys. 46, 217 (1996).

B.Z. Lee and D.N. Lee, Acta Mater. 46, 3701 (1998).

K.W. Moon, M.E. Williams, C.E. Johnson, and G.R. Stafford, C.A. Handwerker, and W.J. Boettinger, Proc. 4th Pacific Rim Int. Conf. on Advanced Materials and Processing (Sendai, Japan: Japan Institute of Metals, 2001), pp. 1115–1118.

R. Schety, Circ. World 27-2, 17 (2001).

T. Nagai, K. Natori, and T. Furusawa, J. Jpn. Inst. Met. 53, 303 (1989).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kim, KS., Matsuura, T. & Suganuma, K. Effects of Bi and Pb on oxidation in humidity for low-temperature lead-free solder systems. J. Electron. Mater. 35, 41–47 (2006). https://doi.org/10.1007/s11664-006-0182-1

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11664-006-0182-1