Abstract

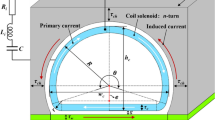

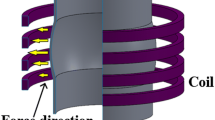

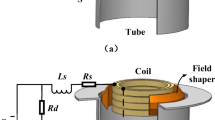

The bulk metallic electromagnetic levitation technique has a promising application prospect in condensed physics and materials science. In order to resolve the problem of weak levitation force and the small size of samples, an optimized solution based on finite element analysis (FEA) is developed to seek the best electromagnetic field distribution in the levitation zone. The influence of material properties on the distribution of magnetic flux density, surface pressure, and the Lorentz force were studied by the FEA method with various sample sizes of titanium and copper balls. The levitation capability of cylindrical coil system which consists of a single-layer coil with an inner diameter of 30 mm and the levitated object with a diameter of 20 mm was analyzed. To keep a balance between the turn number and increment efficiency of force, the best number of 7 turns is confirmed. Then, two types of optimized coils were predicted by numerical simulations, and the levitation force is improved drastically. The double-layer coil displays an outstanding levitation capability owing to the strong electromagnetic field generated by multilayer turns. In addition, 5 to 50 g aluminum, titanium, copper, and nickel are levitated by the above three kinds of coils and the levitation capacities are validated from the recorded data of the minimum operating current that can levitate the samples. The experimental results show good agreements with the simulation results, and the minimum current for optimized coils is reduced efficiently.

Similar content being viewed by others

REFERENCES

J. E. Rodriguez, C. Kreischer, T. Volkmann, and D. M. Matson, Acta Mater., 2017, vol. 122, pp. 431-437.

P. Lü and H. P. Wang, Scr. Mater., 2017, vol. 137, pp. 31-35.

G. Lohofer and S. Schneider, High Temp.-High Press., 2016, vol. 45, pp. 255-271.

A. Schmon, K. Aziz, and G. Pottlacher, Metall. Mater. Trans. A, 2015, vol. 46, pp. 2674-2679.

D. L. Price: High-temperature levitated materials. Cambridge University Press, New York, 2010, p. 94.

A. J. Sangster: Fundamentals of Electromagnetic Levitation: Engineering Sustainability Through Efficiency. The Institution of Engineering and Technology, London, 2012, p. 56.

S. Asai: Electromagnetic Processing of Materials: Materials Processing by Using Electric and Magnetic Functions. Springer Science & Business Media, Dordrecht, 2012, p. 87.

S. I. Bakhtiyarov and D. A. Siginer, Fluid Dyn. Mater. Process., 2008, vol. 4, pp. 163-184.

K. Zhou, H. P. Wang, J. Chang, and B. Wei, Chem. Phys. Lett., 2015, vol. 639, pp. 105-108.

S. I. Bakhtiyarov and D. A. Siginer, Fluid Dyn. Mater. Process., 2009, vol. 5, pp. 1-22.

A. V. Mohammadi and M. Halali, RSC Advances, 2014, vol. 4, pp. 7104-7108.

M. Vaghayenegar, A. Kermanpur, M. H. Abbasi, and H. Ghasemi Yazdabadi, Adv. Powder Technol., 2010, vol. 21, pp. 556-563.

A. Kermanpur, M. Jafari, and M. Vaghayenegar, J. Mater. Process. Technol., 2011, vol. 211, pp. 222-229.

A. Khodaei, M. Hasannasab, N. Amousoltani, and A. Kermanpur, Mater. Res. Bull., 2016, vol. 74, pp. 212-217.

G. Yoshikawa, K. Hirata, and F. Miyasaka, IEEE T. Magn., 2011, vol. 47, pp. 1394-1397.

Y. H. Wu, J. Chang, W. L. Wang, L. Hu, S. J. Yang, and B. Wei, Acta Mater., 2017, vol. 129, pp. 366-377.

A. Bansal, P. Chapelle, Y. Delannoy, E. Waz, P. Le Brun, and J. P. Bellot, Metall. Mater. Trans. B, 2015, vol. 46, pp. 2096-2109.

L. Gao, Z. Shi, D. Li, G. Zhang, Y. Yang, A. McLean, and K. Chattopadhyay, Metall. Mater. Trans. B, 2015, vol. 47, pp. 537-547.

V. Bojarevics, A. A. Roy, and K. Pericleous, Magnetohydrodynamics, 2010, vol. 46, pp. 317-329.

W. H. Sillekens, D. J. Jarvis, A. Vorozhtsov, V. Bojarevics, C. F. Badini, M. Pavese, S. Terzi, L. Salvo, L. Katsarou, and H. Dieringa, Metall. Mater. Trans. A, 2014, vol. 45A, pp. 3349-3361.

V. Bojarevics, G. S. Djambazov, and K. A. Pericleous, Metall. Mater. Trans. A, 2015, vol. 46A, pp. 2884-2892.

S. R. Sagardia and R. Segsworth, IEEE T. Ind. Appl., 1977, vol. IA-13, pp. 49-52.

M. Bullo, F. Dughiero, M. Forzan, and S. Lupi, Magnetohydrodynamics, 2007, vol. 43, pp. 151-159.

L. Feng and W. Y. Shi, Metall. Mater. Trans. B, 2015, vol. 46, pp. 1895-1901.

B. Li and S. Song, Microgravity Sci. Technol., 1998, vol. 11, pp. 134-143.

S. Spitans, E. Baake, B. Nacke, and A. Jakovics, Metall. Mater. Trans. B, 2016, vol. 47, pp. 522-536.

J. Lee, X. Xiao, D. M. Matson, and R. W. Hyers, Metall. Mater. Trans. B, 2015, vol. 46, pp. 199-207.

Z. L. Royer, C. Tackes, R. Lesar, and R. E. Napolitano, J. Appl. Phys., 2013, vol. 113, p. 214901.

S. Roberts, S. Kok, J. Zietsman, and H. Inglis: 11th World Congress on Structural and Multidisciplinary Optimization, Sydney, 2015.

Z. Moghimi, M. Halali, and M. Nusheh, Metall. Mater. Trans. B, 2006, vol. 37, pp. 997-1005.

S. I. Bakhtiyarov and D. A. Siginer, Fluid Dyn. Mater. Process., 2008, vol. 4, pp. 99-112.

K. F. Wang, S. Chandrasekar and Henry T. Y. Yang, J. Mater. Eng. Perform., 1992, vol. 1, pp. 97-112.

W. Brisley and B. S. Thornton, Br. J. Appl. Phys., 1963, vol. 14, pp. 682-686.

L. Gao, Z. Shi, D. Li, A. McLean, and K. Chattopadhyay, Metall. Mater. Trans. B, 2016, vol. 47, pp. 1905-1915.

V. Bojarevics and K. Pericleous, ISIJ international, 2003, vol. 43, pp. 890-898.

A. R. Conn, K. Scheinberg, and L. N. Vicente: Introduction to derivative-free optimization. the Mathematical Programming Society and the Society for Industrial and Applied Mathematics, Philadelphia, 2009, p. 115.

Acknowledgments

The authors are very grateful to Dr. Y.H. Wu and Mr. S.J. Yang for their valuable discussions. They also thank Mr. M.X. Li for his help with the experiments. This work is financially supported by the National Natural Science Foundation of China (Grant Nos. 51327901, 51474175, 51522102 and 51734008) and the Fundamental Research Funds for the Central Universities.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 15, 2018.

Rights and permissions

About this article

Cite this article

Cai, X., Wang, H.P., Lü, P. et al. Optimized Electromagnetic Fields Levitate Bulk Metallic Materials. Metall Mater Trans B 49, 2252–2260 (2018). https://doi.org/10.1007/s11663-018-1333-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-018-1333-5