Abstract

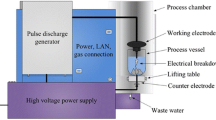

Copper slag is composed of iron silicate obtained by smelting copper concentrate and silica flux. One of the most important criteria for the utilization of this secondary resource is the recovery of iron from the slag matrix to decrease the volume of dumped slag. The molten oxidation process with crushing magnetic separation appears to be a more sustainable approach and is based on directly blowing oxidizing gas onto molten slag after the copper smelting process. In the current study, using an infrared furnace, the crystallization behavior of the slag during molten oxidation was studied to better understand the trade-off between magnetite and hematite precipitations, as assessed by X-ray diffraction (using an internal standard). Furthermore, the crystal morphology was examined using a laser microscope and Raman imaging system to understand the iron oxide transformation, and the distribution of impurities such as Cu, Zn, As, Cr, and Pb were complemented with scanning electron microscopy and energy dispersive spectroscopy. In addition, the reaction mechanism was investigated with a focus on the oxidation processes.

Similar content being viewed by others

References

Alexander, L., Klug, H. P.: Anal. Chem., 1948 20, 886-889.

Fan, Y., Shibata, E., Iizuka, A., Nakamura, T.: J. MMIJ., 2013, vol. 5, 177-184.

Fan, Y., Shibata, E., Iizuka, A., Nakamura, T.: Mater. Trans., 2014, vol. 55, 958-963.

Phase Equilibria Diagrams Database 31, 2004–2014. The American Ceramic Society and the U.S. Secretary of Commerce.

Samsonov, G. V., 1982. The oxide handbook. IFI Plenum, New York, 53.

Sasabe, M., Kinoshita, Y.: Iron Steel Inst., 1979, vol. 12, 1727-1736.

Sasabe, M., Jibiki, M.: Iron Steel Inst., 1982, vol. 7, 767-773.

Sasabe, M., Jibiki, M.: Can. Metall. Q., 1983, vol. 22, 29-36.

Sayadyaghoubi, Y., Sun, S., Jahanshahi, S.: Metall. Mater. Trans. B., 1995, vol. 26, 795-802.

Stumm, W., Morgan, J. J., 2013. World Mineral Production 2007-11, Keyworth. Nottingham.

AcknowledgmentS

The laser microscope and Raman imaging system used in the current study were provided by the High Efficiency Rare Elements Extraction Technology Area under the Tohoku Innovation Materials Technology Initiatives for Reconstruction from the Ministry of Education, Culture, Sports, Science, and Technology in Japan.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 3, 2015.

Rights and permissions

About this article

Cite this article

Fan, Y., Shibata, E., Iizuka, A. et al. Crystallization Behavior of Copper Smelter Slag During Molten Oxidation. Metall Mater Trans B 46, 2158–2164 (2015). https://doi.org/10.1007/s11663-015-0365-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-015-0365-3