Abstract

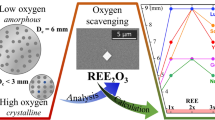

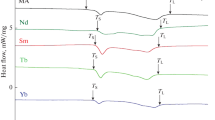

Glass-forming alloys are very sensitive to oxygen contaminations. Here, the oxygen-scavenging effect of five rare-earth elements (REEs) was studied when added to the Zr50Cu40Al10 alloy, synthesized from commercially available zirconium. The effects of precise REEs additions (Y, Sc, Lu, Gd, Nd) with respect to the measured oxygen content, based on the stoichiometric relationship in the M2O3 oxide, are reported. Additionally, the influence of double and triple REE-to-oxygen ratios on the critical diameter (Dc) and other glass-forming ability (GFA) indicators were investigated. To evaluate the GFA and phase transformations during heating, differential thermal analysis was performed along with neutron diffraction. The combination of these two techniques allowed to identify crystallization products and distinguish the differences in phase transformations of low and high-oxygen-content alloys. Microstructural analysis was carried out by means of electron microscopy (SEM, STEM), supported by X-ray diffraction. The best oxygen scavengers were found to be rare earths that form cubic sesquioxides, i.e., Y, Sc, and Lu, allowing to increase Dc in the high-oxygen Zr50Cu40Al10 alloy from 2.5 mm up to 8 mm (double-stoichiometric concentration of Y-to-oxygen). Our results indicate that low-purity alloys can be easily vitrified, highlighting their potential for wide commercialization.

Similar content being viewed by others

References

E.D. Zanotto and J.C. Mauro: J. Non. Cryst. Solids, 2017, vol. 471, pp. 490–95. https://doi.org/10.1016/j.jnoncrysol.2017.05.019.

J. Zhao, Z. Tang, K.F. Kelton, C.T. Liu, P.K. Liaw, A. Inoue, X. Shen, S. Pan, M.L. Johnson, G. Chen, and C. Fan: Intermetallics, 2017, vol. 82, pp. 53–58. https://doi.org/10.1016/j.intermet.2016.11.010.

T. Kozieł, K. Pajor, G. Cios, and P. Bała: Trans. Nonferrous Met. Soc. China, 2019, vol. 29, pp. 1036–45. https://doi.org/10.1016/S1003-6326(19)65012-0.

T. Kozieł, K. Pajor, and Ł Gondek: J. Mater. Res. Technol., 2020, vol. 9, pp. 13502–08. https://doi.org/10.1016/j.jmrt.2020.09.082.

H.S. Chen: Acta Metall., 1974, vol. 22, pp. 1505–11. https://doi.org/10.1016/0001-6160(74)90112-6.

A. Inoue: Acta Mater., 2000, vol. 48, pp. 279–306. https://doi.org/10.1016/S1359-6454(99)00300-6.

M.M. Khan, A. Nemati, Z.U. Rahman, U.H. Shah, H. Asgar, and W. Haider: Crit. Rev. Solid State Mater. Sci., 2018, vol. 43, pp. 233–68. https://doi.org/10.1080/10408436.2017.1358149.

E. Axinte: Mater. Des., 2012, vol. 35, pp. 518–56. https://doi.org/10.1016/j.matdes.2011.09.028.

J. Cheng, G. Chen, Q. Zeng, L. Yun, and F. Xu: J. Iron Steel Res. Int., 2016, vol. 23, pp. 78–82. https://doi.org/10.1016/S1006-706X(16)30016-4.

P. Błyskun, T. Kozieł, K. Pajor, P. Maj, and T. Kulik: J. Non. Cryst. Solids, 2019, vol. 509, pp. 80–87. https://doi.org/10.1016/j.jnoncrysol.2019.01.026.

X.H. Lin, W.L. Johnson, and W.K. Rhim: Mater. Trans. JIM., 1997, vol. 38, pp. 473–77.

Y. Yokoyama, T. Shinohara, K. Fukaura, and A. Inoue: Mater. Trans., 2004, vol. 45, pp. 1819–23. https://doi.org/10.2320/matertrans.45.1819.

V. Keryvin, C. Bernard, J.C. Sanglebœuf, Y. Yokoyama, and T. Rouxel: J. Non. Cryst. Solids, 2006, vol. 352, pp. 2863–68. https://doi.org/10.1016/j.jnoncrysol.2006.02.102.

Z.P. Lu, H. Bei, Y. Wu, G.L. Chen, E.P. George, and C.T. Liu: Appl. Phys. Lett., 2008, vol. 92, pp. 23–25. https://doi.org/10.1063/1.2828981.

K.T. Park, T.H. Lee, N.C. Jo, H.H. Nersisyan, B.S. Chun, H.H. Lee, and J.H. Lee: J. Nucl. Mater., 2013, vol. 436, pp. 130–38. https://doi.org/10.1016/j.jnucmat.2013.01.310.

R.A. Robie, B.S. Hemingway, J.R. Fisher: Thermodynamic Properties of Minerals and Related Substances at 298.15K and 1 Bar Pressure and at Higher Temperatures, UNITED STATES GOVERNMENT PRINTING OFFICE, Washington, 1978. https://doi.org/10.3133/b1452.

M. Zinkevich: Prog. Mater. Sci., 2007, vol. 52, pp. 597–647. https://doi.org/10.1016/j.pmatsci.2006.09.002.

A.A. Kündig, D. Lepori, A.J. Perry, S. Rossmann, A. Blatter, A. Dommann, and P.J. Uggowitzer: Mater. Trans., 2002, vol. 43, pp. 3206–10. https://doi.org/10.2320/matertrans.43.3206.

K. Pajor, T. Kozieł, G. Cios, P. Błyskun, P. Bała, and A. Zielińska-Lipiec: J. Non. Cryst. Solids, 2018, vol. 496, pp. 42–47. https://doi.org/10.1016/j.jnoncrysol.2018.05.034.

Y. Zhang, M.X. Pan, D.Q. Zhao, R.J. Wang, and W.H. Wang: Mater. Trans. JIM, 2000, vol. 41, pp. 1410–14.

J. Luo, H. Duan, C. Ma, S. Pang, and T. Zhang: Mater. Trans., 2006, vol. 47, pp. 450–53. https://doi.org/10.2320/matertrans.47.450.

J. Chen, Y. Zhang, J.P. He, K.F. Yao, B.C. Wei, and G.L. Chen: Scr. Mater., 2006, vol. 54, pp. 1351–55. https://doi.org/10.1016/j.scriptamat.2005.12.002.

J. Zhu, C. Wang, J. Han, S. Yang, G. Xie, H. Jiang, Y. Chen, and X. Liu: Intermetallics, 2018, vol. 92, pp. 55–61. https://doi.org/10.1016/j.intermet.2017.08.018.

K. Zhou, Y. Liu, S. Pang, and T. Zhang: J. Alloys Compd., 2016, vol. 656, pp. 389–94. https://doi.org/10.1016/j.jallcom.2015.09.254.

S. Lu, S. Sun, K. Li, H. Li, X. Huang, and G. Tu: J. Alloys Compd., 2019, vol. 799, pp. 501–12. https://doi.org/10.1016/j.jallcom.2019.05.219.

H.-P. Cui, W.-D. Zhang, and C.-L. Song: Chin. J. Mech. Eng., 2021, https://doi.org/10.21203/rs.3.rs-349393/v1.

F. Jiang, Z.J. Wang, Z.B. Zhang, and J. Sun: Scr. Mater., 2005, vol. 53, pp. 487–91. https://doi.org/10.1016/j.scriptamat.2005.05.003.

K. Zhou, C. Chen, Y. Liu, S. Pang, N. Hua, W. Yang, and T. Zhang: Intermetallics, 2017, vol. 90, pp. 81–89. https://doi.org/10.1016/j.intermet.2017.07.007.

L. Deng, B. Zhou, H. Yang, X. Jiang, B. Jiang, and X. Zhang: J. Alloys Compd., 2015, vol. 632, pp. 429–34. https://doi.org/10.1016/j.jallcom.2015.01.036.

Y. Ke, F. Xinhui, L. Bing, L. Yanhong, and W. Xin: Vacuum, 2021, vol. 187, 110078https://doi.org/10.1016/j.vacuum.2021.110078.

X. Xu, L.Y. Chen, G.Q. Zhang, L.N. Wang, and J.Z. Jiang: Intermetallics, 2007, vol. 15, pp. 1066–70. https://doi.org/10.1016/j.intermet.2006.12.010.

X.I.E. Zhiwei, Z. Yongzhang, Y. Yuanzheng, C. Xianzhao, T.A.O. Pingjun, Z. Xie, Y. Zhang, Y. Yang, X. Chen, and P. Tao: Rare Met., 2010, vol. 29, pp. 444–50. https://doi.org/10.1007/s12598-010-0147-7.

W.H. Wang: Prog. Mater. Sci., 2007, vol. 52, pp. 540–96. https://doi.org/10.1016/j.pmatsci.2006.07.003.

N. Chen, L. Martin, D.V. Luzguine-Luzgin, and A. Inoue: Materials, 2010, vol. 3, pp. 5320–39. https://doi.org/10.3390/ma3125320.

X.Y. Liu: J. Chem. Phys., 2000, vol. 112, pp. 9949–55. https://doi.org/10.1063/1.481644.

K. Pajor, T. Kozieł, B. Rutkowski, G. Cios, P. Błyskun, D. Tyrała, P. Bała, and A. Zielińska-Lipiec: Metall. Mater. Trans. A, 2020, vol. 51A, pp. 4563–71. https://doi.org/10.1007/s11661-020-05875-1.

Z. Long, W. Liu, M. Zhong, Y. Zhang, M. Zhao, G. Liao, and Z. Chen: J. Therm. Anal. Calorim., 2018, vol. 132, pp. 1645–60. https://doi.org/10.1007/s10973-018-7050-0.

Ł Rakoczy, B. Rutkowski, M. Grudzień-Rakoczy, R. Cygan, W. Ratuszek, and A. Zielińska-Lipiec: Materials, 2020, vol. 13, pp. 1–24. https://doi.org/10.3390/ma13194452.

J. Łażewski, M. Sternik, P.T. Jochym, J. Kalt, S. Stankov, A.I. Chumakov, J. Göttlicher, R. Rüffer, T. Baumbach, and P. Piekarz: Inorg. Chem., 2021, vol. 60, pp. 9571–79. https://doi.org/10.1021/acs.inorgchem.1c00708.

K.K. Song, S. Pauly, Y. Zhang, P. Gargarella, R. Li, N.S. Barekar, U. Kühn, M. Stoica, and J. Eckert: Acta Mater., 2011, vol. 59, pp. 6620–30. https://doi.org/10.1016/j.actamat.2011.07.017.

R. Ramachandramoorthy, F. Yang, D. Casari, M. Stolpe, M. Jain, J. Schwiedrzik, J. Michler, J.J. Kruzic, and J.P. Best: J. Mater. Res., 2021, vol. 36, pp. 2325–36. https://doi.org/10.1557/s43578-021-00187-5.

K.J. Laws, B. Gun, and M. Ferry: Metall. Mater. Trans. A, 2009, vol. 40A, pp. 2377–87. https://doi.org/10.1007/s11661-009-9929-7.

P. Błyskun, M. Kowalczyk, G. Cieślak, and T. Kulik: J. Non. Cryst. Solids, 2019, vol. 515, pp. 106–12. https://doi.org/10.1016/j.jnoncrysol.2019.04.018.

C. Suryanarayana and A. Inoue: Bulk Metallic Glasses, 2nd ed. CRC Press, Boca Raton, 2017, pp. 9–34.

Y. Chen, C. Tang, and J.Z. Jiang: Prog. Mater. Sci., 2021, vol. 121, 100799https://doi.org/10.1016/j.pmatsci.2021.100799.

A. Inoue and A. Takeuchi: Acta Mater., 2011, vol. 59, pp. 2243–67. https://doi.org/10.1016/j.actamat.2010.11.027.

W. Zhou, Y. Meng, F. Duan, W. Huang, J. Yao, J. Pan, Y. Wang, and Y. Li: Intermetallics, 2021, vol. 129, 107055https://doi.org/10.1016/j.intermet.2020.107055.

D. Wang, H. Tan, and Y. Li: Acta Mater., 2005, vol. 53, pp. 2969–79. https://doi.org/10.1016/j.actamat.2005.03.012.

Y.F. Xu, L.P.H. Jeurgens, L.C. Lin, S. Ma, S.L. Zhu, Y. Huang, Y.C. Liu, J.W. Qiao, and Z.M. Wang: Corros. Sci., 2021, vol. 183, 109309https://doi.org/10.1016/j.corsci.2021.109309.

O. Baulin, T. Douillard, D. Fabrègue, M. Perez, J.M. Pelletier, and M. Bugnet: Mater. Des., 2019, vol. 168, 107660https://doi.org/10.1016/j.matdes.2019.107660.

The Materials Project. Materials Data on ZrAlCu2 by Materials Project (United States 2020), https://doi.org/10.17188/1207352. Accessed 31 Jan 2022

The Materials Project. Materials Data on Zr6Al7Cu16 by Materials Project (United States 2020), Web. https://doi.org/10.17188/1733902. Accessed 31 Jan 2022

J.L. Soubeyroux, N. Claret, and J.M. Pelletier: Mater. Sci. Forum., 2001, vol. 360–362, pp. 37–42. https://doi.org/10.4028/www.scientific.net/msf.360-362.37.

J. Eckert, N. Mattern, M. Zinkevitch, and M. Seidel: Mater. Trans. JIM, 1998, vol. 39, pp. 623–32. https://doi.org/10.2320/matertrans1989.39.623.

H. Okamoto: J. Phase Equilibria Diffus., 2012, vol. 33, pp. 417–18. https://doi.org/10.1007/s11669-012-0077-1.

S. Zhang, T. Ichitsubo, Y. Yoshihiko, K. Miyagi, and E. Matsubara: Mater. Sci. Forum, 2007, vol. 561, pp. 1391–95.

S. Zhang, T. Ichitsubo, Y. Yokoyama, T. Yamamoto, E. Matsubara, and A. Inoue: Mater. Trans., 2009, vol. 50, pp. 1340–45. https://doi.org/10.2320/matertrans.MBW200833.

K. Kosiba and S. Pauly: Sci. Rep., 2017, vol. 7, p. 2151. https://doi.org/10.1038/s41598-017-02376-x.

Q. Zheng, Y. Zhang, M. Montazerian, O. Gulbiten, J.C. Mauro, E.D. Zanotto, and Y. Yue: Chem. Rev., 2019, vol. 119, pp. 7848–7939. https://doi.org/10.1021/acs.chemrev.8b00510.

Q. Cheng, X. Han, I. Kaban, I. Soldatov, W.H. Wang, Y.H. Sun, and J. Orava: Scr. Mater., 2020, vol. 183, pp. 61–65. https://doi.org/10.1016/j.scriptamat.2020.03.028.

T. Yamamoto, Y. Yokoyama, T. Ichitsubo, H. Kimura, E. Matsubara, and A. Inoue: J. Mater. Res., 2010, vol. 25, pp. 793–800. https://doi.org/10.1557/JMR.2010.0105.

N.D. de Campos Neto, F.S. Pereira, S.G. Antonio, Y. Guo, A.J. Clarke, M.J. Kaufman, and M.F. de Oliveira: Mater. Charact., 2019, vol. 158, pp. 1–7. https://doi.org/10.1016/j.matchar.2019.109932.

Q. Zhang, W. Zhang, and A. Inoue: Mater. Trans., 2006, vol. 47, pp. 2804–07. https://doi.org/10.2320/matertrans.47.2804.

Q. Hu, M.W. Fu, and X.R. Zeng: Mater. Des., 2014, vol. 64, pp. 301–06. https://doi.org/10.1016/j.matdes.2014.07.057.

T. Schleid and G. Meyer: J. Less-Common Met., 1989, vol. 149, pp. 73–80. https://doi.org/10.1016/0022-5088(89)90472-4.

E.R. Andrievskaya, V.V. Kovylyaev, L.M. Lopato, A.V. Ragulya, and A.V. Shevchenko: Inorg. Mater., 2000, vol. 36, pp. 612–19. https://doi.org/10.1007/BF02757964.

A. Shevchenko, L. Lopato, and I. Kiryakova: Inorg. Mater., 1984, vol. 20, pp. 1731–36.

G.T. Adylov, V.G. Voronov, and L. Sigalov: Inorg. Mater., 1987, vol. 23, pp. 1644–46.

D. Taylor: Trans. J. Br. Ceram. Soc., 1984, vol. 83, pp. 92–98.

Acknowledgments

This work was financially supported by the Ministry of Science and Higher Education Republic of Poland under Contract No. 16.16.110.663. K.W. was supported by the EMPAPOSTDOCS-II program that has received funding from the European Union’s Horizon 2020 research and innovation program under the Marie Skłodowska-Curie Grant Agreement Number 754364.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pajor, K., Rutkowski, B., Gondek, Ł. et al. The Scavenging Effect of Different Rare-Earth Elements in the Low-Purity Zr50Cu40Al10 Alloy. Metall Mater Trans A 53, 2902–2925 (2022). https://doi.org/10.1007/s11661-022-06714-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06714-1