Abstract

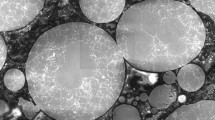

Fabrication of high strength aluminum alloys using laser-based powder bed fusion (L-PBF) encounters challenges, including the occurrence of solidification cracks and the loss of volatile elements, such as Zn and Mg. The current work developed a Si-modified Al7075 alloy aiming at introducing eutectic phases to mitigate the solidification cracking during L-PBF. Based on Kou’s model, the addition of Zn and Mg decreased the crack susceptibility from 6504 °C to 5966 °C, and the addition of 3.74 wt pct of Si further decreased the crack susceptibility to 3960 °C. The Al7075 alloy fabricated by L-PBF exhibited a large amount of solidification cracks extending throughout the sample. Crack-free samples with a relative density of 99.94 pct, as inspected by X-ray microcomputed tomography, were achieved for the developed Si-modified Al7075 alloy. The microstructure showed a transition from a coarse columnar microstructure to a refined mixed columnar + equiaxed microstructure after alloy modification, with a concomitant grain size reduction from 59.0 ± 42.2 to 15.0 ± 9.4 µm. Moreover, Si, Mg2Si, and Al2Cu phases were detected in the Si-modified Al7075 alloy. After a direct ageing heat treatment, the Si-modified Al7075 alloy showed minimal age hardening effect with a peak hardness of (146 ± 3 Hv).

Similar content being viewed by others

References

1 S.D. Nath, H. Irrinki, G. Gupta, M. Kearns, O. Gulsoy, and S. Atre: Powder Technol., 2019, vol. 343, pp. 738–46.

2 D. Herzog, V. Seyda, E. Wycisk, and C. Emmelmann: Acta Mater., 2016, vol. 117, pp. 371–92.

3 L. Xi, D. Gu, K. Lin, S. Guo, Y. Liu, Y. Li, and M. Guo: J. Mater. Res., 2020, vol. 35, pp. 559–70.

P. Rambabu, N. Eswara Prasad, V. V. Kutumbarao, and R.J.H. Wanhill: 2017, pp. 29–52.

5 M. Zuo, M. Sokoluk, C. Cao, J. Yuan, S. Zheng, and X. Li: Sci. Rep., 2019, vol. 9, pp. 1–11.

6 J. Lu, Y. Song, L. Hua, K. Zheng, and D. Dai: J. Alloys Compd., 2018, vol. 767, pp. 856–69.

7 F. Bosio, A. Aversa, M. Lorusso, S. Marola, D. Gianoglio, L. Battezzati, P. Fino, D. Manfredi, and M. Lombardi: Mater. Des., 2019, vol. 181, p. 107949.

K. Nishimoto, K. Saida, K. Kiuchi, and J. Nakayama: Influence of Minor and Impurity Elements on Hot Cracking Susceptibility of Extra High-Purity Type 310 Stainless Steels, 2011.

H. Zhao and T. Debroy: Metall. Mater. Trans. B., 2001, vol. 32, pp. 163–72.

G. Agarwal, A. Kumar, H. Gao, M. Amirthalingam, S.C. Moon, R.J. Dippenaar, I.M. Richardson, and M.J.M. Hermans: Metall. Mater. Trans. A, 2018, vol. 49, pp. 1015–20.

11 A. Aversa, G. Marchese, A. Saboori, E. Bassini, D. Manfredi, S. Biamino, D. Ugues, P. Fino, and M. Lombardi: Materials (Basel)., 2019, vol. 12, p. 1007.

T. Boellinghaus, J.C. Lippold, and C.E.C. Editors: Cracking Phenomena in Welds IV. Springer, Cham, 2016.

13 G. Agarwal, A. Kumar, I.M. Richardson, and M.J.M. Hermans: Mater. Des., 2019, vol. 183, p. 108104.

14 P.A. Hooper: Addit. Manuf., 2018, vol. 22, pp. 548–59.

15 M.L. Montero-Sistiaga, Z. Liu, L. Bautmans, S. Nardone, G. Ji, J.-P. Kruth, J. Van Humbeeck, and K. Vanmeensel: Addit. Manuf., 2020, vol. 31, p. 100995.

16 R. Mertens, S. Dadbakhsh, J. Van Humbeeck, and J.P. Kruth: Procedia CIRP, 2018, vol. 74, pp. 5–11.

17 D. Buchbinder, W. Meiners, N. Pirch, K. Wissenbach, and J. Schrage: J. Laser Appl., 2014, vol. 26, p. 012004.

18 M. Chen, X. Li, G. Ji, Y. Wu, Z. Chen, W. Baekelant, K. Vanmeensel, H. Wang, and J.-P. Kruth: Appl. Sci., 2017, vol. 7, p. 250.

19 P. Wang, C. Gammer, F. Brenne, T. Niendorf, J. Eckert, and S. Scudino: Compos. Part B Eng., 2018, vol. 147, pp. 162–8.

20 D. Carluccio, M.J. Bermingham, Y. Zhang, D.H. StJohn, K. Yang, P.A. Rometsch, X. Wu, and M.S. Dargusch: J. Manuf. Process., 2018, vol. 35, pp. 715–20.

21 M. Sokoluk, C. Cao, S. Pan, and X. Li: Nat. Commun., 2019, vol. 10, pp. 1–8.

22 J.H. Martin, B.D. Yahata, J.M. Hundley, J.A. Mayer, T.A. Schaedler, and T.M. Pollock: Nature, 2017, vol. 549, pp. 365–9.

23 L. Zhou, H. Pan, H. Hyer, S. Park, Y. Bai, B. McWilliams, K. Cho, and Y. Sohn: Scr. Mater., 2019, vol. 158, pp. 24–8.

24 Z. Lei, J. Bi, Y. Chen, X. Chen, X. Qin, and Z. Tian: Powder Technol., 2019, vol. 356, pp. 594–606.

25 H. Hu, M. Zhao, X. Wu, Z. Jia, R. Wang, W. Li, and Q. Liu: J. Alloys Compd., 2016, vol. 681, pp. 96–108.

26 F. Sun, G.L. Nash, Q. Li, E. Liu, C. He, C. Shi, and N. Zhao: J. Mater. Sci. Technol., 2017, vol. 33, pp. 1015–22.

27 G. Bo, F. Jiang, Z. Dong, G. Wang, and H. Zhang: Mater. Sci. Eng. A, 2019, vol. 755, pp. 147–57.

M.L. Montero Sistiaga, R. Mertens, B. Vrancken, X. Wang, B. Van Hooreweder, J.P. Kruth, and J. Van Humbeeck: J. Mater. Process. Technol., 2016, vol. 238, pp. 437–45.

29 C. Huang, G. Cao, and S. Kou: Sci. Technol. Weld. Join., 2004, vol. 9, pp. 149–57.

30 M. Rappaz, J.M. Drezet, and M. Gremaud: Metall. Mater. Trans. A, 1999, vol. 30, pp. 449–55.

31 S. Kou: Acta Mater., 2015, vol. 88, pp. 366–74.

32 J. Liu and S. Kou: Acta Mater., 2017, vol. 125, pp. 513–23.

33 P. Schaffnit, C. Stallybrass, J. Konrad, F. Stein, and M. Weinberg: Calphad Comput. Coupling Phase Diagrams Thermochem., 2015, vol. 48, pp. 184–8.

G.H. Gulliver: The Quantitative Effect of Rapid Cooling upon the Constitution of Binary Alloys, vol. 9, 1913.

35 R. Cohn, B. Fullenwider, K. Ma, and J.M. Schoenung: Adv. Eng. Mater., 2018, vol. 20, pp. 1–7.

36 N.T. Aboulkhair, M. Simonelli, L. Parry, I. Ashcroft, C. Tuck, and R. Hague: Prog. Mater. Sci., 2019, vol. 106, p. 100578.

X. Gong, T. Anderson, and K. Chou: Manuf. Rev., https://doi.org/10.1051/mfreview/2014001.

38 S.M. Gaytan, L.E. Murr, F. Medina, E. Martinez, M.I. Lopez, and R.B. Wicker: Mater. Technol., 2009, vol. 24, pp. 180–90.

39 L. Thijs, K. Kempen, J.P. Kruth, and J. Van Humbeeck: Acta Mater., 2013, vol. 61, pp. 1809–19.

40 T. Böllinghaus, H. Herold, C.E. Cross, and J.C. Lippold: Hot Cracking Phenomena in Welds II, Springer-Verlag Berlin Heidelberg, 2008.

41 J.C. Lippold: Weld. Metall. Weldability, 2014, vol. 9781118230, pp. 1–400.

42 M. Kang and C. Kim: J. Weld. Join., 2017, vol. 35, pp. 79–88.

A.M. Mitrašinović and F.C.R. Hernández: Mater. Sci. Eng. A, 2012, vol. 540, pp. 63–69.

44 Y.J. Liu, Z. Liu, Y. Jiang, G.W. Wang, Y. Yang, and L.C. Zhang: J. Alloys Compd., 2018, vol. 735, pp. 1414–21.

45 L. Zhou, H. Pan, H. Hyer, S. Park, Y. Bai, B. McWilliams, K. Cho, and Y. Sohn: Scr. Mater., 2019, vol. 158, pp. 24–8.

46 K.R. Ramkumar, H. Bekele, and S. Sivasankaran: Adv. Mater. Sci. Eng., 2015, vol. 2015, pp. 1–14.

47 A. Hadadzadeh, B.S. Amirkhiz, and M. Mohammadi: Mater. Sci. Eng. A, 2019, vol. 739, pp. 295–300.

E. Sjölander and S. Seifeddine: Metall. Mater. Trans. A 2014, vol. 45, pp. 1916–27.

49 A.M. Samuel, J. Gauthier, and F.H. Samuel: Metall. Mater. Trans. A, 1996, vol. 27, pp. 1785–98.

50 V.C. Pierre, B. Anthony, T. Lore, V.H. Brecht, and V. Kim: Euro PM 2018 Congr. Exhib., 2020, pp. 1–7.

Acknowledgments

This work was funded by the European Union’s Horizon 2020 Clean Sky 2 research and innovation program under grant agreement No 755610, project AlForAMA. The authors acknowledge the support from the topic manager, Leonardo Aircraft. L-PBF experiments were conducted thanks to the KU Leuven funding under contract number GOA/15/012 - Sustainable Material Processing in Manufacturing. The X-ray computed tomography facilities of KU Leuven is acknowledged for the X-ray µ-CT inspections. G. Li wishes to thank the China Scholarship Council (Grant No. 201706220083) for financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted May 5, 2020; accepted October 17, 2020.

Electronic Supplementary material

Below is the link to the Electronic Supplementary material.

Rights and permissions

About this article

Cite this article

Li, G., Jadhav, S.D., Martín, A. et al. Investigation of Solidification and Precipitation Behavior of Si-Modified 7075 Aluminum Alloy Fabricated by Laser-Based Powder Bed Fusion. Metall Mater Trans A 52, 194–210 (2021). https://doi.org/10.1007/s11661-020-06073-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-06073-9