Abstract

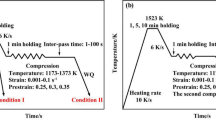

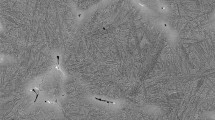

Heavy reduction (HR) is used to implement a large reduction amount to improve the internal quality and refine the microstructure of continuous casting billets with large section sizes. In this paper, microstructural evolution and dynamic recrystallization (DRX) kinetic models for continuous casting slabs under HR were investigated for an experimental temperature range from [1173 K to 1573 K (900 °C) to (1300 °C)] and strain rates of 0.001 to 0.1 s−1. Based on the experimental data, various DRX kinetics models for a continuous casting slab as functions of the strain rate, strain, initial austenite grain size, and temperature were established to predict DRX-induced softening behaviors. A comparison of the new modified model, with Laasraoui and Jonas’s model, the modified Yoda’s model, and Liu’s model, revealed that the new modified model is the most suitable model for a continuous casting slab under HR. Based on this research, constitutive models with the characteristics of DRX and dynamic recovery (DRV) were established to predict the flow stress curve with the parameters of the strain rate (\( \dot{\varepsilon } \)), deformation temperature (T), and the initial austenite grain size (d0). Moreover, the microstructural evolution of a tested slab after hot compression tests was investigated by optical microscopy and a DRX grain size model under different deformation conditions was established.

Similar content being viewed by others

Abbreviations

- HR:

-

Heavy reduction

- SR:

-

Soft reduction

- DRX:

-

Dynamic recrystallization

- DRV:

-

Dynamic recovery

- WH:

-

Work hardening

- Z:

-

Zener–Hollomon parameter \( \left(Z = \dot{\varepsilon }\exp \left( {\frac{Q}{\text{RT}}} \right)\right) \)

- \( \theta \) :

-

WH rate is the derivative of flow stress curves (\( \theta = {\text{d}}\sigma /{\text{d}}\varepsilon \))

- \( \varepsilon_{\text{p}} \), \( \varepsilon_{\text{c}} \) :

-

Peak strain and critical strain, MPa

- \( \varepsilon^{*} \) :

-

Strain when the velocity of DRX is maximum

- \( \varepsilon_{0.5} \) :

-

Strain for 50 pct dynamic recrystallization

- \( \sigma_{\text{DRV}} \), \( \sigma_{\text{DRX}} \) :

-

The flow stress if the DRV and DRX is the main softening mechanism

- Ω:

-

Which is dependent on the deformation temperature and the strain rate, is the coefficient of DRV

- D DRX :

-

Austenite grain size when the dynamic recrystallization occurs completely

- \( \sigma_{\text{p}} \), \( \sigma_{\text{c}} \), \( \sigma_{0} \), \( \sigma_{\text{s}} \) and \( \sigma_{\text{ss}} \) :

-

Peak stress, critical stress, yield stress, saturation stress, and steady-state stress, MPa

- \( \dot{\varepsilon } \) :

-

Strain rate, s−1

- T:

-

Temperature, K

- d 0 :

-

Initial austenite grain size, μm

- σ :

-

Flow stress, MPa

- Q:

-

Deformation activation energy, J mol−1

References

C. Ji, Z.L. Wang, C.H. Wu and M.Y. Zhu: Metall. Mater. Trans. B, 2018, vol. 49, pp. 1-16.

C. Ji, C.H. Wu and M.Y. Zhu: JOM, 2016, vol. 68, pp. 3107-15.

Q.P. Dong, J.M. Zhang, B. Wang and X.K. Zhao: J. Mater. Process. Technol, 2016, vol. 238, pp. 81-8.

Z.G. Xu, X.H. Wang and M. Jiang: Steel Res. Int., 2017, vol. 88, pp. 231-42.

Y.X. Liu, Y.C. Lin, H.B. Li, D.X. Wen, X. M. Chen and M.S. Chen: Mater. Sci. Eng., A, 2015, vol. 626, pp. 432-40.

Y.W. Xu, D. Tang, Y. Song and X.G. Pan: Mater. Des., 2012, vol. 39, pp. 168-74.

A. Momeni, K. Dehghani, H. Keshmiri and G.R. Ebrahimi: Mater. Sci. Eng., A, 2010, vol. 527, pp. 1605-11.

S. Mandal, A.K. Bhaduri and V.S. Sarma: Metall. Mater. Trans. A, 2011, vol. 42, pp. 1062-72.

N. Mortazavi, N. Bonora, A. Ruggiero and M.H. Colliander: Metall. Mater. Trans. A, 2016, vol. 47A, pp. 2555-9.

S. Serajzadeh: Modell. Simul. Mater. Sci. Eng., 2004, vol. 12, pp. 1185-200.

A.I. Fernández, P, Uranga, B, López and J.M. Rodriguez-Ibabe: Mater. Sci. Eng., A, 2003, vol. 361, pp. 367-76.

X. Quelennec and J.J. Jonas: ISIJ Int., 2012, vol. 52, pp. 1145-52.

A. Momeni, S.M. Abbas, M. Morakabati, H. Badri and X. Wang: Mater. Sci. Eng., A, 2014, vol. 615, pp. 51-60.

G.R. Ebrahimi, H. Keshmiri, A.R. Maldar and A. Momeni: J. Mater. Sci. Technol., 2012, vol. 28, pp. 467-73.

X.M. Chen, Y.C. Lin, D.X. Wen, J.L. Zhang and H. Min: Mater. Des., 2014, vol. 57, pp. 568-77.

A.N. Kolmogorov: Izv. Akad. Nauk. SSSR., 1937, vol. 3, pp. 355-59.

W.A. Johnson and R.F. Mehl: Trans. Am. Inst. Min.Metall. Engrs., 1939, vol. 135, pp. 416.

M. Avrami: J. Chem. Phys., 1939, vol. 7, pp. 1103.

M. Avrami: J. Chem. Phys., 1940, vol. 8, pp. 212.

M. Avrami: J. Chem. Phys., 1941, vol. 9, pp. 177.

C.M. Sellars and J.A. Whiteman: Met. Sci., 1979, vol. 13, pp. 187-94.

C.M. Sellars: Mater. Sci. Technol., 1990, vol. 6, pp. 1072-81.

D.X. Wen, Y.C. Lin and Y. Zhou: Vacuum, 2017, vol. 141, pp. 316-27.

G.Z. Quan, D.S.Wu, G.C. Luo, Y.F. Xia, J. Zhou, Q. Liu and L. Gao: Mater. Sci. Eng., A, 2014, vol. 589, pp. 22-33.

H. Yada and T. Senuma: J. Jpn. Soc. Technol. Plast., 1986, vol. 27, pp. 34.

S.I. Kim, Y. Lee, D.L. Lee and Y.C. Yoo: Mater. Sci. Eng., A, 2003, vol. 355, pp. 384-93.

A. Laasraoui and J.J. Jonas: Metall. Trans. A, 1991, vol. 22A, pp. 151-60.

X.K. Zhao, J.M. Zhang, S.W. Lei and Y.N. Wang: Steel Res. Int., 2013, vol. 85, pp. 811-23.

M.N. Gong, H.J. Li, T.X. Li, B. Wang, and Z.D. Wang: Steel Res. Int., 2018, vol. 89, art. no. 1800025.

C. Zener and J.H. Hollomon: J. Appl. Phys., 1944, vol. 15, pp. 22-32.

C.M. Sellars and W.M. Tegart: Acta Metall., 1966, vol. 14, pp. 1136-38.

H.J. Mcqueen, S. Yue, N.D. Ryan and E. Fry: J. Mater. Process. Technol., 1995, vol. 53, pp. 293-310.

Y. Han, H. Wu, W. Zhang, D.N. Zou, G.W. Liu and G.J. Qiao: Mater. Des., 2015, vol. 69, pp. 230-40.

S. Saadatkia and H. Mirzadeh, and J.M. Cabrera: Mater. Sci. Eng., A, 2015, vol. A636, pp. 196-202.

H.L. Wei and G.Q. Liu: Mater. Des., 2014, vol. 56, pp. 437-44.

M. Shaban and B. Eghbali: Mater. Sci. Eng., A, 2010, vol. 527, pp. 4320-25.

Z.X. Xie, Q.Y. Liu, J.H. Yang and G.Y. Gan: J. Iron Steel Res., 2009, vol. 21, pp. 33-6 (in Chinese).

S.L. Zhu, H.Z. Cao, J.S. Ye, W.H. Hu, and G.Q. Zheng: J. Iron Steel Res. Int., 2015, vol. 22, pp. 264-71.

E.I. Poliak and J.J. Jonas: ISIJ Int., 2003, vol. 43, pp. 692-700.

N. D. Ryan and H. J. McQueen: Can. Metall. Q., 1990, vol. 29, pp. 147.

A. Yanagida and J. Yanagimoto: J. Mater. Process. Technol., 2004, vol. 151, pp. 33-8.

Y.C. Lin, M.S. Chen and J. Zhang: Mech. Res. Commun., 2008, vol. 35, pp. 142-50.

A. Najafizadeh and J.J. Jonas: ISIJ Int., 2006, vol. 46, pp. 1679-84.

M. Wahabi, J.M. Cabrera and J.M. Prado: Mater. Sci. Eng., A, 2003, vol. 343, pp. 116-25.

L.X. Kong, P.D. Hodgson and B. Wang: J. Mater. Process. Technol., 1999, vol. 90, pp. 44-50.

Z.Y. Zeng, L.Q. Chen, F.X. Zhu, and X.H. Liu: J. Mater. Sci. Technol., 2011, vol. 27, pp. 913-19.

F. Kocks and H. Mecking: Acta Metall., 1981, vol. 29, pp. 1865-75.

Y. Estrin and H. Mecking: Acta Metall., 1984, vol. 32, pp. 57-70.

Y. Bergström: Mater. Sci. Eng., 1970, vol. 5, pp. 193-200.

S. Serajzadeh and A.K. Taheri: Mech. Res. Commun., 2003, vol. 30, pp. 87-93.

R. Kopp, M.L. Cao and M.D. Souza: in Proceedings of the Second International Conference on Technology of Plasticity, 1987, pp. 1129–34.

J. Liu, Z. Cui and L. Ruan: Mater. Sci. Eng., A, 2011, vol. 529, pp. 300-10.

V. Torabinejad, A. Zarei-Hanzaki, and S. Moemeni: Mater. Manuf. Process., 2012, vol. 28, pp. 36-41.

D.Z. Li, Y.H. Wei, C.Y. Liu, and L.F. Hou: Steel Res. Int., 2013, vol. 84, pp. 740-50.

Y.C. Lin, Y.X. Lin, G. Liu, M.S. Chen and Y.C. Huang: J. Mater. Eng. Perform., 2015, vol. 24, pp. 221-8.

Acknowledgments

The current study was financially supported by the National Natural Science Foundation of China under Grant Nos. 51474058 and U1708259; the Program for Liaoning Excellent Talents in University (LJQ2015036); and the Fundamental Research Funds for the Central Universities of China (N172504024). Special thanks are due to the cooperating company for industrial trials and application.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 14, 2018.

Rights and permissions

About this article

Cite this article

Yang, Q., Ji, C. & Zhu, M. Modeling of the Dynamic Recrystallization Kinetics of a Continuous Casting Slab Under Heavy Reduction. Metall Mater Trans A 50, 357–376 (2019). https://doi.org/10.1007/s11661-018-5005-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-5005-5