Abstract

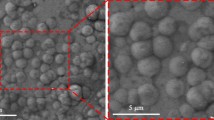

The interfacial microstructures of Sn-3.0Ag-0.5Cu (SAC305) solder systems with thin Ni(P) mono-coatings and Cu-Ni(P) dual-coatings were investigated after reflowing and isothermal aging. The ultrathin mono-Ni(P) plating of the SAC305/Ni(P) solder joint was found to rapidly decompose and then transform into a Ni2SnP phase. An intermetallic compound (IMC) formed at the plating/substrate interface, indicating that the ultrathin mono-Ni(P) plating was not an effective diffusion barrier. However, only a single IMC layer ((Cu,Ni)6Sn5) formed at the solder/plating interface in the SAC305/Cu/Ni(P)/Cu system. The (Cu,Ni)6Sn5 IMC effectively suppressed atomic diffusion, protecting the Ni(P) plating and Cu substrate. Although P-Sn-O pores formed in the root of the (Cu,Ni)6Sn5 IMC layer, the dual-Cu/Ni(P) plating protected the solder system for an extended period. The IMC growth rate constants of the SAC305/Cu, SAC305/Ni(P), and SAC305/Cu/Ni(P)/Cu solder joint systems were 0.180, 0.342, and 0.068 μm/h1/2, respectively. These results indicate that the application of dual-Cu/Ni(P) plating can effectively hinder the growth of IMC.

Similar content being viewed by others

References

J.W. Nah, J.H. Kim, H.M. Lee and K.W. Paik: Acta Mater., 2004, vol. 52, pp. 129-36.

Y. Ding, C.Q. Wang, Y.H. Tian, and B.B. Zhang: Metall. Mater. Trans. A., 2006, vol. 37, pp.1017-25.

V. Kumar, Z. Z. Fang, J. Liang and N. Dariavach: Metall. Mater. Trans. A., 2006, vol. 37, pp. 2505-14

X. Gu, K.C. Yung, Y.C. Chan and D. Yang: J. Mater. Sci. - Mater. Electron., 2011, vol. 22, pp. 217-22

DG Kim, JW Kim, SB Jung (2005) Mater. Sci. Eng. B 121:204-10.

S.R.A. Idris: Ph.D. Dissertation, University Teknologi Malaysia, 2008.

P. Sungkhaphaitoon and T. Plookphol: Metall. Mater. Trans. A, 2018, vol. 49, pp. 652-60.

A Sharif, MN Islam, YC Chan (2004) Mater. Sci. Eng. B 113:184-89.

HT Lee, MH Chen, HM Jao, TL Liao (2003) Mater. Sci. Eng. A 358:134-41.

L. Meinshausen: Ph.D. Dissertation, Electronics. University de Bordeaux, 2014.

J. Yu and K. Kim: Metall. Mater. Trans. A, 2015, vol. 46, pp. 3173-81.

S. Eraslan and M. Ürgen: Surf. Coat. Technol., 2015, vol. 265, pp. 46-52.

Katarzyna N., Braszczyńska-Malik and Jacek Kamieniak: Metall. Mater. Trans. A, 2017, vol. 48, pp. 5649-57.

T.R. Tamilarasan, R. Rajendran, G. Rajagopal and J. Sudagar: Surf. Coat. Technol., 2015, vol. 276, pp. 320-6.

Y.C. Lin and J.G. Duh: Scripta Mater., 2006, vol. 54, pp. 1661-5.

Y.C. Lin, T.Y. Shih, S.K. Tien and J.G. Duh: Scripta Mater., 2007, vol. 56, pp. 49-52.

Y.C. Lin, K.J. Wang and J.G. Duh: J. Electron. Mater., 2010, vol. 39, pp. 283-94.

S.P. Peng, W.H. Wu, C.E. Ho and Y.M. Huang: J. Alloys Compd., 2010, vol. 493, pp. 431-7.

W.H. Wu, C.S. Lin, S.H. Huang and C.E. Ho: J. Electron. Mater., 2010, vol. 39, pp. 2387-96.

C.E. Ho, C.W. Fan and W.Z. Hsieh: Surf. Coat. Technol., 2014, vol. 259, pp. 244-51.

C.Y. Ho, J.G. Duh, C.W. Lin, C.J. Lin and Y.H. Wu: J. Mater. Sci., 2013, vol. 48, pp. 2724-32.

C.Y. Liu and S.J. Wang: J. Electron. Mater., 2003, vol. 32, pp. 1303-9.

S.J. Wang and C.Y. Liu: Scripta Mater., 2003, vol. 49, pp. 813-8.

B Lee, H Jeon, KW Kwon, HJ Lee (2013) Acta Mater. 61: 6736-42.

J. Liang, N. Dariavach, P. Callahan and D. Shangguan: Mater. Trans., 2006, vol. 47, pp. 317-25.

P. Chen, X. Zhao, Y. Wang, Y. Liu, H. Li and Y. Gu: J. Mater. Sci. - Mater. Electron., 2015, vol. 26, pp. 1940-9.

X. Hu, T. Xu, L.M. Keer, Y. Li and X. Jiang: J. Alloys Compd., 2017, vol. 690, pp. 720-9.

M. Haerifar and M. Zandrahimi: Appl. Surf. Sci., 2013, vol. 284, pp. 126-32.

CW Liu, YL Wang, MS Tsai, HP Feng, SC Chang (2005) J. Vac. Sci. Technol. A 23:658-62.

Quéré D: Annu. Rev. Mater. Res., 2008, vol. 38, pp. 71-99.

W. Liu and D.P. Sekulic: Langmuir, 2011, vol. 27, pp. 6720-30.

J.W. Yoon and S.B. Jung: J. Mater. Sci., 2004, vol. 39, pp. 4211-7.

P.T. Vianco, J.A. Rejent and P.F. Hlava: J. Electron. Mater., 2004, vol. 33, pp. 991-1004.

J.Y. Park, C.W. Yang, J.S. Ha, C.U. Kim, E.J. Kwon, S.B. Jung and C.S. Kang: J. Electron. Mater., 2001, vol. 30, pp. 1165-70.

C.Y. Ho, J.G. Duh, C.W. Lin, C.J. Lin, Y.H. Wu, H.C. Hong and T.H. Wang: J. Mater.Sci., 2013, vol. 48, pp. 2724-32.

Y.C Lin, K.J. Wang and J.G. Duh: J .Electron. Mater., 2010, vol. 39, pp. 283-94.

C.Y. Ho, J.G. Duh: Mater. Chem. Phys., 2014, vol. 148, pp. 21-7.

V. Vuorinen, T. Laurila, H. Yu and J.K. Kivilahti: J. Appl. Phys., 2006, vol. 99, pp. 3530-36.

Z. Chen, A. Kumar and M. Mona: J. Electron. Mater., 2006, vol. 35, pp. 2126-34.

C.E. Ho, C.W. Fan, W.H. Wu and T.T. Kuo: Thin Solid Films, 2013, vol. 529, pp. 364-8.

W.M. Chen, S.C. Yang, M.H. Tsai and C.R. Kao: Scripta Mater., 2010, vol. 63, pp. 47-9.

K.N. Tu and K. Zeng: Mater. Sci. Eng. R, 2001, vol. 34, pp. 1-58..

W. Peng, E. Monlevade and M.E. Marques: Microelectron. Reliab., 2007, vol. 47, pp. 2161-8.

J. Shen, M. Zhao, P. He and Y. Pu: J. Alloys Compd., 2013, vol. 574, pp. 451-8.

D.G. Kim and S.B. Jung: J. Alloys Compd., 2005, vol. 386, pp. 151-6.

Acknowledgments

This study was supported by the Nature Science Foundation of China (No. 51465039, 51765040), and the Nature Science Foundation of Jiangxi Province (20161BAB206122).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Manuscript submitted January 15, 2018.

Rights and permissions

About this article

Cite this article

Zhang, Z., Hu, X., Jiang, X. et al. Influences of Mono-Ni(P) and Dual-Cu/Ni(P) Plating on the Interfacial Microstructure Evolution of Solder Joints. Metall Mater Trans A 50, 480–492 (2019). https://doi.org/10.1007/s11661-018-4983-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-4983-7