Abstract

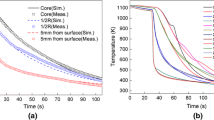

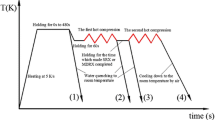

The study of internal stress in quenched AISI 4140 medium carbon steel is of importance in engineering. In this work, the finite element simulation (FES) was employed to predict the distribution of internal stress in quenched AISI 4140 cylinders with two sizes of diameter based on exponent-modified (Ex-Modified) normalized function. The results indicate that the FES based on Ex-Modified normalized function proposed is better consistent with X-ray diffraction measurements of the stress distribution than FES based on normalized function proposed by Abrassart, Desalos and Leblond, respectively, which is attributed that Ex-Modified normalized function better describes transformation plasticity. Effect of temperature distribution on the phase formation, the origin of residual stress distribution and effect of transformation plasticity function on the residual stress distribution were further discussed.

Similar content being viewed by others

Notes

JEOL is a trademark of Japan Electron Optics Ltd., Tokyo.

References

X.W. Zuo, N.L. Chen, F. Gao, and Y.H. Rong: Int. Heat Treat. Surf. Eng., 2014, vol. 8, pp. 15–23.

T. Inoue and K. Arimoto: J. Mater. Eng. Perform., 1997, vol. 6, pp. 51–60.

S. Denis, S. Sjöström, and A. Simon: Metall. Trans. A, 1987, vol. 18A, pp. 1203–12.

C. Şimşir and C.H. Gür: J. Mater. Process. Technol., 2008, vol. 207, pp. 211–21.

M. Jung, M. Kang, and Y.K. Lee: Acta Mater., 2012, vol. 60, pp. 525–36.

S.J. Lee and Y.K. Lee: Acta Mater., 2008, vol. 56, pp. 1482–90.

E.A. Ariza, M.A. Martorano, N.B. de Lima, and A.P. Tschiptschin: ISIJ Int., 2014, vol. 54, pp. 1396–1405.

P. Ferro and F. Bonollo: Modell. Simul. Mater. Sci. Eng., 2014, vol. 22, p. 025019.

B.L. Ferguson, Z. Li, and A.M. Freborg: Comput. Mater. Sci., 2005, vol. 34, pp. 274–81.

D.Y. Ju, R. Mukai, and T. Sakamaki: Int. Heat Treat. Surf. Eng., 2011, vol. 5, pp. 65–68.

DEFORM™-HT: http://www.deform.com/products/deform-ht/.

F.D. Fischer, Q.P. Sun, and K. Tanaka: Appl. Mech. Rev., 1996, vol. 49, pp. 317–64.

F.D. Fischer, G. Reisner, E. Werner, K. Tanaka, G. Cailletaud, and T. Antretter: Int. J. Plast., 2000, vol. 16, pp. 723–48.

S. Denis, E. Gautier, A. Simon, and G. Beck: Mater. Sci. Technol., 1985, vol. 1, pp. 805–14.

X. Yao, L. Zhu, and M.V. Li: Int. J. Microstr. Mater. Prop., 2010, vol. 5, pp. 501–23.

S. Denis, A. Simon, and G. Beck: Trans. Iron Steel Inst. Jpn., 1982, vol. 22, pp. 504–13.

F.G. Rammerstorfer, D.F. Fischer, W. Mitter, K.J. Bathe, and M.D. Snyder: Comput. Struct., 1981, vol. 13, pp. 771–79.

J.B. Leblond, J. Devaux, and J.C. Devaux: Int. J. Plast., 1989, vol. 5, pp. 551–72.

J.B. Leblond: Int. J. Plast., 1989, vol. 5, pp. 573–91.

J. Rohde and A. Jeppsson: Scand. J. Metall., 2000, vol. 29, pp. 47–62.

L. Taleb, N. Cavallo, and F. Waeckel: Int. J. Plast., 2001, vol. 17, pp. 1–20.

A.K. De, J.G. Speer, and D.K. Matlock: Adv. Mater. Process., 2003, vol. 161, pp. 27–30.

Non-Destructive Testing—Test Method for Residual Stress Analysis by X-ray Diffraction, European Standard EN15305, 2008.

D.T. Kang and H. Zhang: Trans. Met. Heat Treatment, 1983, vol. 4, pp. 61–77.

J.B. Leblond, G. Mottet, J. Devaux, and J.C. Devaux: Mater. Sci. Technol., 1985, vol. 1, pp. 815–22.

T.Y. Hsu: Mater. Sci. Eng. A, 2006, vols. 438–440, pp. 64–68.

F.M.B. Fernandes, S. Denis, and A. Simon: Mater. Sci. Technol., 1985, vol. 1, pp. 838–44.

A. Bejan and Allan D. Kraus: Heat Transfer Handbook, John Wiley & Sons, Inc., Hoboken, NJ, 2003, pp. 165–67.

M.E. Kakhki, A. Kermanpur, and M.A. Golozar: Modell. Simul. Mater. Sci. Eng., 2009, vol. 17, p. 045007.

George F. Vander Voort: Atlas of Time-Temperature Diagrams for Irons and Steels, ASM INTERNATIONAL, Materials Park, OH, 1991, p. 140.

J.S. Kirkaldy and D. Venugopalan: in Phase Transformation in Ferrous Alloys, A.R. Marder and J.I. Goldstein, eds., TMS-AIME, Warrendale, PA, 1984, pp. 126–47.

S.J. Lee: Adv. Mater. Res., 2013, vols. 798–799, pp. 39–44.

D.P. Koistinen and R.E. Marburger: Acta Metall., 1959, vol. 7, pp. 59–60.

S.J. Lee and C.J. Van Tyne: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 422–27.

S.J. Lee and K.S. Park: Metall. Mater. Trans. A, 2013, vol. 44A, pp. 3423–27.

Y.K. Lee: J. Mater. Sci. Lett., 2002, vol. 21, pp. 1253–55.

M. Fanfoni and M. Tomellini: Il Nuovo Cimento D, 1998, vol. 20, pp. 1171–82.

G.T. Houlsby and A.M. Puzrin: Principles of Hyperplasticity, Springer London, London, 2007, pp. 13–33.

S. Petit-Grostabussiat, L. Taleb, and J.F. Jullien: Int. J. Plast., 2004, vol. 20, pp. 1371–86.

J.B. Leblond, G. Mottet, and J.C. Devaux: J. Mech. Phys. Solids, 1986, vol. 34, pp. 411–32.

R. Schröder: Mater. Sci. Technol., 1985, vol. 1, pp. 754–64.

W.P. de Oliveira, M.A. Savi, P.M.C.L. Pacheco, and L.F.G. de Souza: Mech. Mater., 2010, vol. 42, pp. 31–43.

H.S. Yu: Plasticity and Geotechnics, Springer US, Boston, MA, 2006, pp. 492–93.

Q.G. Hao, S.W. Qin, Y. Liu, X.W. Zuo, N.L. Chen, W. Huang, and Y.H. Rong: Mater. Sci. Eng. A, 2016, vol. 662, pp. 16–25.

K. Zhang, M.H. Zhang, Z.H. Guo, N.L. Chen, and Y.H. Rong: Mater. Sci. Eng. A, 2011, vol. 528, pp. 8486–91.

S.W. Qin, Y. Liu, Q.G. Hao, Y. Wang, N.L. Chen, X.W. Zuo, and Y.H. Rong: Metall. Mater. Trans. A, 2015, vol. 46A, pp. 4047–55.

Y. Wang, K. Zhang, Z.H. Guo, N.L. Chen, and Y.H. Rong: Mater. Sci. Eng. A, 2012, vol. 552, pp. 288–94.

D. Ivanov and L. Markegard: HTM J. Heat Treat. Mater., 2016, vol. 71, pp. 99–104.

Acknowledgment

This work was financially supported by the National Natural Science Foundation of China (Grant No. 51371117).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 23, 2016.

Rights and permissions

About this article

Cite this article

Liu, Y., Qin, S., Hao, Q. et al. Finite Element Simulation and Experimental Verification of Internal Stress of Quenched AISI 4140 Cylinders. Metall Mater Trans A 48, 1402–1413 (2017). https://doi.org/10.1007/s11661-016-3916-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3916-6