Abstract

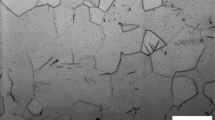

The corrosion behavior of multi-pass friction stir processed (FSP) pure titanium was studied in 0.5 M H2SO4 solutions. Microstructures of treated and untreated samples were characterized using scanning electron microscopy. It was found that the grain size decreased with increasing the number of applied passes of FSP. Electrochemical tests including potentiodynamic polarization measurements and electrochemical impedance spectroscopy showed that three passes of FSP treatments resulted in a Ti sample which exhibited the best passive behavior and had the highest corrosion resistance among all samples in strongly acidic solutions of 0.5 M H2SO4. These improvements can be attributed to the emergence of diverse structural defects and grain refinement induced by FSP treatments. Moreover, Mott–Schottky analysis was performed to investigate the semiconducting properties of passive films. It was found that the semiconducting behavior remained the same after FSP treatments but it reduced donor densities and surprisingly introduced an additional donor level.

Similar content being viewed by others

References

D. W. Shoesmith and J. J. Noël: Non-Ferrous Metals and Alloys, Elsevier Ltd, Amsterdam, 2010.

R. R. Boyer: Mater. Sci. Eng. A, 1996, vol 213 (1-2), pp. 103-114.

V. N. Moiseyev; Titanium Alloys, Taylor & Francis Group, New York, 2006.

M. Yamada: Mater. Sci. Eng. A, 1996, vol. 213 (1-2), pp. 8-15.

J. Komotori, B. Lee, H. Dong, and P. Dearnley: Wear, 2001, vol. 251 (1-12), pp. 1239-1249.

J. Pouilleau, D. Devilliers, F. Garrido, S. Durand-vidal, and E. Mahé: Mater. Sci. Eng. B, 1997, vol. 47 (3), pp. 235-243.

P. D. Bianco, P. Ducheyne, and J. M. Cuckler: J. Biomed. Mater. Res. A, 1996, vol. 31 (2), pp. 227-234.

H. S. Kim, S. J. Yoo, J. W. Ahn, D. H. Kim, and W. J. Kim: Mater. Sci. Eng. A, 2011, vol. 528 (29-30), pp. 8479-8485.

E. K. Sevidova and A. A. Simonova: Surf. Eng. Appl. Electrochem., 2011, vol. 47(2), pp. 162–66.

M. Hoseini, A. Shahryari, S. Omanovic, and J. a. Szpunar: Corros. Sci., 2009, vol. 51(12), pp. 3064–67.

L. Jin, W. Cui, X. Song, G. Liu, and L. Zhou; Trans. Nonferrous Met. Soc. China, 2014, vol. 24(6), pp. 2529-2535.

J. Li, S. J. Li, Y. L. Hao, H. H. Huang, Y. Bai, Y. Q. Hao, Z. Guo, J. Q. Xue, and R. Yang: Acta Biomater., 2014, vol. 10 (6), pp. 2866-2875.

J. Tang, H. Y. Luo, and Y. B. Zhang: Int. J. Adv. Manuf. Technol., 2016, doi:10.1007/s00170-016-9000-y.

S. Mironov, Y. S. Sato, and H. Kokawa: Acta Materialia, 2009, vol. 57 (15), pp. 4519-4528.

W.-B. Lee, C.-Y. Lee, W.-S. Chang, Y.-M. Yeon, and S.-B. Jung: Mater. Lett., 2005, vol. 59 (26), pp. 3315-3318.

F. J. Humphreys and M. Hatherly: Recrystallization and Related Annealing Phenomena, Elsevier Ltd, Amsterdam, 2004.

R.S. Mishra, P. S. De, N. Kumar: Friction Stir Welding and Processing: Science and Engineering, Springer International Publishing, Switzerland, 2014.

M. Nie, C. T. Wang, M. Qu, N. Gao, J. A. Wharton, and T. G. Langdon: J. Mater. Sci., 2014, vol. 49, pp. 2824–31.

K. D. Ralston and N. Birbilis: Corrosion, 2010, vol. 66(7), pp. 075005(1–13).

F. C. Liu, J. Liao, Y. Gao, and K. Nakata: J. Alloys Compd., 2015, vol. 626, pp. 304-308.

Z. Y. Ma: Metall. Mater. Trans. A, 2008, vol. 39 (3), pp. 642-658.

J. A. Petit, G. Chatainier, and F. Dabosi: Corros. Sci., 1981, vol. 21 (4), pp. 279-299.

S. Hrapovic, B. L. Luan, M. D. Amours, G. Vatankhah, and G. Jerkiewicz: Langnuir, 2001, vol. 17 (10), pp. 3051-3060.

H. Garbacz, M. Pisarek, and K. J. Kurzydłowski: Biomol. Eng., 2007, vol. 24 (6), pp. 559-563.

M. Schönleber, D. Klotz, and E. Ivers-Tiffée: Electrochim. Acta, 2014, vol. 131, pp. 20-27.

B.A. Boukamp, Solid State Ionics, 1993, vol. 62 (1-2), pp. 131-141.

A. Fattah-Alhosseini and S. Vafaeian: Appl. Surf. Sci., 2016, vol. 360(B), pp. 921–28.

B. Hirschorn, M.E. Orazem, B. Tribollet, V. Vivier, I. Frateur and M. Musiani: J. Electrochem. Soc., 2010, vol. 157 (12), pp. C452-C457.

L. Hamadou, L. Aïnouche, A. Kadri, S. A. A. Yahia, and N. Benbrahim: Electrochim. Acta, 2013, vol. 113, pp. 99-108.

B. Hirschorn, M. E. Orazem, B. Tribollet, V. Vivier, I. Frateur, and M. Musiani: J. Electrochem. Soc., 2010, vol. 157 (12), pp. C458-C463.

M. E. Orazem, I. Frateur, B. Tribollet, V. Vivier, S. Marcelin, N. Pebere, A. L. Bunge, E. A. White, D. P. Riemer, and M. Musiani: J. Electrochem. Soc., 2013, vol. 160 (6), pp. C215-C225.

E. McCafferty, Introduction to Corrosion Science: Chapter 9, Passivity, pp. 209–262, Springer, New York, 2010.

S. P. Harrington and T. M. Devine: J. Electrochem. Soc., 2008, vol. 155 (8), pp. C381-C386.

R. De Gryse, W. P. Gomes, F. Cardon and J. Vennik: J. Electrochem. Soc., 1975, vol. 122 (5), pp. 711-712.

S. Giménez and J. Bisquert: Photoelectrochemical Solar Fuel Production: chapter 1, Semiconductor Electrochemistry, ed. by L. M. Peter, 2016, pp. 3–40.

M. D. C Belo, N. Hakiki, and M. G. Ferreira: Electrochim. Acta, 1999, vol. 44 (14), pp. 2473-2481.

D. Sazou, K. Saltidou, and M. Pagitsas: Electrochim. Acta, 2012, vol. 76, pp. 48-61.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 25, 2016.

Rights and permissions

About this article

Cite this article

Fattah-Alhosseini, A., Attarzadeh, F.R. & Vakili-Azghandi, M. Effect of Multi-pass Friction Stir Processing on the Electrochemical and Corrosion Behavior of Pure Titanium in Strongly Acidic Solutions. Metall Mater Trans A 48, 403–411 (2017). https://doi.org/10.1007/s11661-016-3854-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3854-3