Abstract

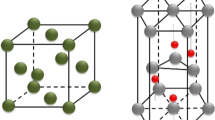

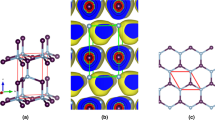

α-Alumina (Al2O3) single crystals with different termination planes were used as heterogeneous nucleation substrates for liquid aluminum to varying lattice misfits at the interface between substrate and newly nucleated aluminum grain. Undercooling during the nucleation process was measured for interface configurations with varied lattice misfit, while the solidified Al/Al2O3 interfaces were directly observed by high-resolution transmission electron microscopy (HRTEM). Based on experimental results, the effect of lattice misfit on nucleation behavior was systematically investigated following previous misfit-interfacial energy models, with clarification being made by the undercooling measurement and HRTEM observations of the interfaces in the Al/Al2O3 system. When the misfit is smaller than 13 pct, both experimental results and theoretical analysis show that the currently existing models through modification and incorporating energy calculation can be used to fit the detected undercooling of investigated system. Beyond 13 pct, a new hypothesis was developed to accommodate lattice misfit with stacking faults such as microtwins according to the HRTEM analysis. The interfacial energy is then replaced by the stacking fault energy accumulated in the strained area. It is shown that the lattice misfit plays an important role in determining the heterogeneous nucleation of liquid aluminum. The nucleation undercooling is then able to be predicted by the theoretically calculated interfacial energy using the integrated models developed in the work. The prediction results were also verified by the HRTEM analysis on the nucleation interface of the Al/Al2O3 systems and detected undercooling on corresponding systems.

Similar content being viewed by others

References

K.F. Kelton, and A.L. Greer: Nucleation in Condensed Matter, Pergamon, Oxford, 2010, pp. 19–28.

B. Cantor: Phil. Trans. R. Soc. Lond. A, 2003, vol. 361, pp. 409–417.

O.M. Magnussen, B.M. Ocko, M.J. Regan, K. Penanen, P.S. Pershan, and M. Deutsch: Phys. Rev. Lett., 1995, vol. 74, no. 22, pp. 4444–4447.

S.H. Oh, Y. Kauffmann, C. Scheu, W.D. Kaplan, and M. Rühle: Science, 2005, vol. 310, no. 5748, pp. 661–663.

S.B. Lee, and Y.M. Kim: Acta Mater., 2011, vol. 59, pp. 1383–1388.

M. Gandman, Y. Kauffmann, C.T. Koch, and W.D. Kaplan: Phys. Rev. Lett., 2013, vol. 110, no. 8, p. 086106.

L. Yang, C.E. Birchenall, G.M. Pound, and M.T. Simnad: Acta Metall., 1954, vol. 2, no. 3, pp. 462–469.

M. Qian: Acta Mater., 2007, vol. 55, pp. 943–953.

M. Qian, and J. Ma: J Cryst. Growth, 2012, vol. 355, no. 1, pp. 73–77.

D. Turnbull, and B. Vonnegut: Ind. Eng. Chem., 1952, vol. 44, no. 6, pp. 1292–1298.

F.C. Frank, and J.H. van der Merwe: Proc. R. Soc. A, 1949, vol. 198, no. 1053, pp. 205–216.

J.W. Matthews, and A.E. Blakeslee: J. Cryst. Growth, 1974, vol. 27, pp. 118–125.

R. People, and J.C. Bean: Appl. Phys. Lett., 1985, vol. 47, no. 3, pp. 322–324.

N.H. Fletcher and K.W. Lodge: Epitaxial Growth, Part B, in ed. J. W. Matthews, Academic Press, New York, 1975, pp. 529-530.

R.W. Vook, and C.T. Horng: Philos. Mag., 1976, vol. 33, no. 5, pp. 843–861.

B.L. Bramfitt: Metall. Trans., 1970, vol. 1, no. 7, pp. 1987–1995.

M. Zarif, B. McKay, J. Li, and P. Schumacher: BHM., 2010, vol. 155, no. 11, pp. 506–511.

M. Zarif, B. Mckay, and P. Schumacher: Metall. Mater. Trans. A, 2011, vol. 42A, no. 6, pp. 1684–1691.

L. Yang, M. Xia, and J.G. Li: Mater. Lett., 2014, vol. 132, pp. 52–54.

P.M. Kelly, and M.-X. Zhang: Metall. Mater. Trans. A, 2006, vol. 37A, pp. 833–839.

G.J. Shiflet, and J.H. Van der Merwer: J. Electron. Mater., 1991, vol. 20, pp. 785–791.

M.-X. Zhang, and P.M. Kelly: Acta Mater., 2005, vol. 53, no. 4, pp. 1073–1084.

M.-X. Zhang, and P.M. Kelly: Acta Mater., 2005, vol. 53, no. 4, pp. 1085–1096.

M.-X. Zhang, S.Q. Chen, H.-P. Ren, and P.M. Kelly: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 1077–1086.

M.-X. Zhang, D. Qiu, and P.M. Kelly: Thin Solid Films, 2008, vol. 516, pp. 5498–5502.

R. Feder, and A.S. Nowick: Phys. Rev., 1958, vol. 109, no. 6, pp. 1959–1963.

W.M. Yim, and R.J. Paff: J. Appl. Phys., 1974, vol. 45, no. 3, pp. 1456–1457.

Y. Wang, H.T. Li, and Z. Fan: Trans. Indian Inst. Met., 2012, vol. 65, no. 6, pp. 653–661.

A.M. Pérez-Sierra, J. Pons, R. Santamarta, P. Vermaut, and P. Ochin: Acta Mater., 2015, vol. 93, pp. 164–174.

J.H. van der Merwe: J. Appl. Phys., 1963. vol. 34, no. 1, pp. 117–122.

R. Peierls: Proc. Phys. Soc., 1940, vol. 52, no. 1, pp. 34–37.

F.R.N. Nabarro: Proc. Phys. Soc., 1947, vol. 59, no. 2, pp. 256–272.

J.H. van der Merwe: J. Appl. Phys., 1963, vol. 34, no. 1, pp. 123–127.

Z. Fan: Metall. Mater. Trans. A, 2013, vol. 44A, no. 3, pp. 1409–1418.

W.A. Jesser, and J.W. Matthews: Philos. Mag., 1967, vol. 15, no. 138, pp. 1097–1106.

J.W. Matthews, and A.E. Blakeslee: J. Cryst. Growth, 1975, vol. 29, pp. 273–280.

K. Shiojima: J. Vac. Sci. Technol. B, 2000, vol. 18, no. 1, pp. 37–40.

L. Lu, Z.Y. Gao, B. Shen, F.J. Xu, S. Huang, Z.L. Miao, Y. Hao, Z.J. Yang, G.Y. Zhang, X.P. Zhang, J. Xu, and D.P. Yu: J. Appl. Phys., 2008, vol. 104, p. 123525.

M.J. Weins, H. Gleiter, and B. Chalmers: J. Appl. Phys., 1971, vol. 42, no. 7, pp. 2639–2645.

R.W. Balluffi, Y. Komem, and T. Schober: Surf. Sci., 1972, vol. 31, pp. 68–103.

R.W. Vook: Thin Solid Films, 1979, vol. 64, pp. 91–102.

R.W. Vook: Int. Met. Rev., 1982, vol. 27, no. 4, pp. 209–245.

D. Cherns, and C.J. Kiely: Mater. Sci. Eng. A, 1989, vol. 113, pp. 43–50.

A. Trampert, and K.H. Ploog: Cryst. Res. Technol., 2000, vol. 35, no. 6–7, pp. 793–806.

K.H.L. Zhang, V.K. Lazarov, P.L. Galindo, F.E. Oropeza, D.J. Payne, H.H.-C. Lai, and R.G. Egdell: Cryst. Growth Des., 2012, vol. 12, no. 2, pp. 1000–1007.

N.H. Fletcher: J. Appl. Phys., 1964, vol. 35, no. 1, pp. 234–240.

N.H. Fletcher: Philos. Mag., 1967, vol. 16, no. 139, pp. 159–164.

S. Kibey, J.B. Liu, D.D. Johnson, and H. Sehitoglu: Acta Mater., 2007, vol. 55, no. 20, pp. 6843–6851.

J.P. Hirth, and J. Lothe: Theory of Dislocations, 2nd ed., Krieger Pub. Co, Malabar, 1982, p. 839.

M.I. Baskes: Phys. Rev. B, 1992, vol. 46, no. 5, pp. 2727–2742.

S. Ogata, J. Li, and S. Yip: Science, 2002, vol. 298, no. 25, pp. 807–811.

A. Tiwari, J. Narayan, C. Jin, and A. Kvit: Appl. Phys. Lett., 2002, vol. 80, no. 8, pp. 1337–1339.

Z. Fan, Y. Wang, Y. Zhang, T. Qin, X.R. Zhou, G.E. Thompson, T. Pennycook, and T. Hashimoto: Acta Mater., 2015, vol. 84, pp. 292–304.

A.L. Greer, A.M. Bunn, A. Tronche, P.V. Evans, and D.J. Bristow: Acta Mater., 2000, vol. 48, pp. 2823–2835.

J. Narayan: Acta Mater., 2013, vol. 61, pp. 2703–2724.

P. Pant, J.D. Budai, and J. Narayan: Acta Mater., 2010, vol. 58, pp. 1097–1103.

H. Zhou, M.F. Chisholm, P. Pant, H.J. Chang, J. Gazquez, S.J. Pennycook, and J. Narayan: Appl. Phys. Lett., 2010, vol. 97, no. 12, p. 121914.

D.L. Medlin, K.F. McCarty, R.Q. Hwang, S.E. Guthrie, and M.I. Baskes: Thin Solid Films, 1997, vol. 299, no. 1–2, pp. 110–114.

W.F. Gale, and T.C. Totemeier: Smithells metals reference book, 8th ed., in ed. E. A. Brandes, Thermochemical data, Butterworths, London, 1983, pp. 8-1–14-1.

Acknowledgments

The authors are grateful for the financial support from NSFC (No. 51174134, No. 51474148), Shanghai STC (No. 11JC1405900), and NBRPC (No. 2011CB012900).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 8, 2016.

Rights and permissions

About this article

Cite this article

Wang, L., Yang, L., Zhang, D. et al. The Role of Lattice Misfit on Heterogeneous Nucleation of Pure Aluminum. Metall Mater Trans A 47, 5012–5022 (2016). https://doi.org/10.1007/s11661-016-3691-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3691-4